I'm sure I'm not the first e30 owner to hate the amount of shifter slop you get with a 260 trans. I'm a previous S2000 owner, and once you experience that shifter feel it is hard to be satisfied with anything else. Inspired by Jordan's post on eliminating shifter slop, I decided to try it myself, albeit with a few tweaks.

First, you need to remove the carrier itself from the car. This means dropping whatever is in the way - exhaust, ect. Rejoice, for this is the last time you will have to deal with the bitch clip!

Note that you should NOT need to drop the trans with this method, but until I toss the car on the lift I can't say for certain.

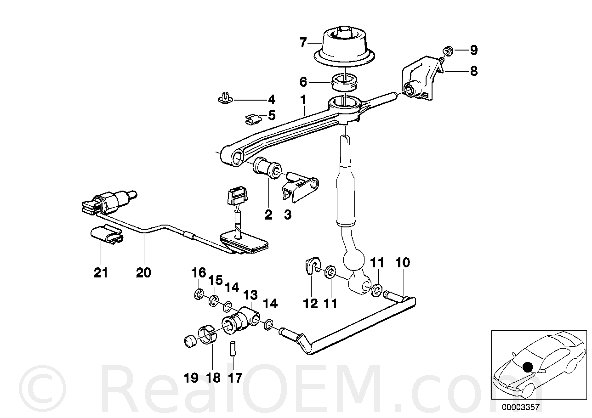

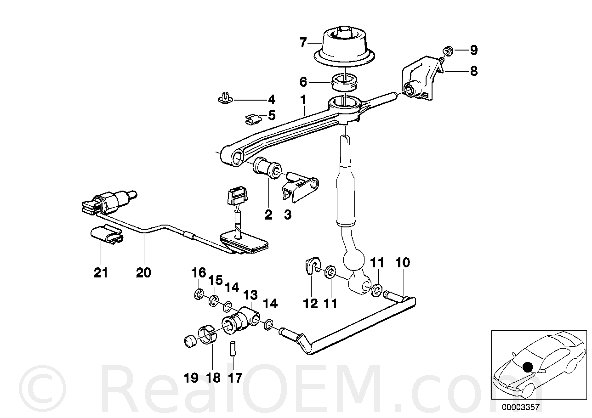

Shifter slop comes from #2 and #8 allowing the carrier itself to move around too much, and from a little bit of play in #13 and the horrible single shear selector rod. This writeup is going to focus on improving #2, #8, and #13.

To improve #2 and eliminate the bitch clip, you'll need to head to a hardware store. Take the bitch clip and carrier with you. I selected a bolt that was the same diameter as the bitch clip so I wouldn't need to do any grinding on the trans itself. I measured the carrier bushing, #2, to be ~3/8" ID and ~5/8" OD, so I picked up a brass sleeve bushing that was 11/16" and found a steel sleeve that allowed the bolt to fit snugly. The brass bushing will likely need to be cut down to fit in where #2 goes, and the carrier itself will need to be ground out (particularly the mold line) to allow it to rotate on the bushing.

When everything is bolted up, the brass bushing should be held in place and kept from rotating as the "ears" on the trans flex enough to clamp it in place. The hole in the carrier should be ground out just large enough that it rotates freely on the brass bushing.

#8 is stupid, and I hate it. Instead of drilling short sheet metal screws around the bushing itself to make it rock solid, I just filled it with the best silicone gasket stuff ever - Honda Bond.

Here's everything all bolted together.

While I was at it I got new clips for the selector rod. I hate this thing. I called Rob over at UUC about the DSSR but he doesn't have one for a 24v swap running the 260 trans :(

Hopefully before the end of the summer I'll be making my own dual shear rod, or find some other solution. Shifter feels great, though!

First, you need to remove the carrier itself from the car. This means dropping whatever is in the way - exhaust, ect. Rejoice, for this is the last time you will have to deal with the bitch clip!

Note that you should NOT need to drop the trans with this method, but until I toss the car on the lift I can't say for certain.

Shifter slop comes from #2 and #8 allowing the carrier itself to move around too much, and from a little bit of play in #13 and the horrible single shear selector rod. This writeup is going to focus on improving #2, #8, and #13.

To improve #2 and eliminate the bitch clip, you'll need to head to a hardware store. Take the bitch clip and carrier with you. I selected a bolt that was the same diameter as the bitch clip so I wouldn't need to do any grinding on the trans itself. I measured the carrier bushing, #2, to be ~3/8" ID and ~5/8" OD, so I picked up a brass sleeve bushing that was 11/16" and found a steel sleeve that allowed the bolt to fit snugly. The brass bushing will likely need to be cut down to fit in where #2 goes, and the carrier itself will need to be ground out (particularly the mold line) to allow it to rotate on the bushing.

When everything is bolted up, the brass bushing should be held in place and kept from rotating as the "ears" on the trans flex enough to clamp it in place. The hole in the carrier should be ground out just large enough that it rotates freely on the brass bushing.

#8 is stupid, and I hate it. Instead of drilling short sheet metal screws around the bushing itself to make it rock solid, I just filled it with the best silicone gasket stuff ever - Honda Bond.

Here's everything all bolted together.

While I was at it I got new clips for the selector rod. I hate this thing. I called Rob over at UUC about the DSSR but he doesn't have one for a 24v swap running the 260 trans :(

Hopefully before the end of the summer I'll be making my own dual shear rod, or find some other solution. Shifter feels great, though!

Comment