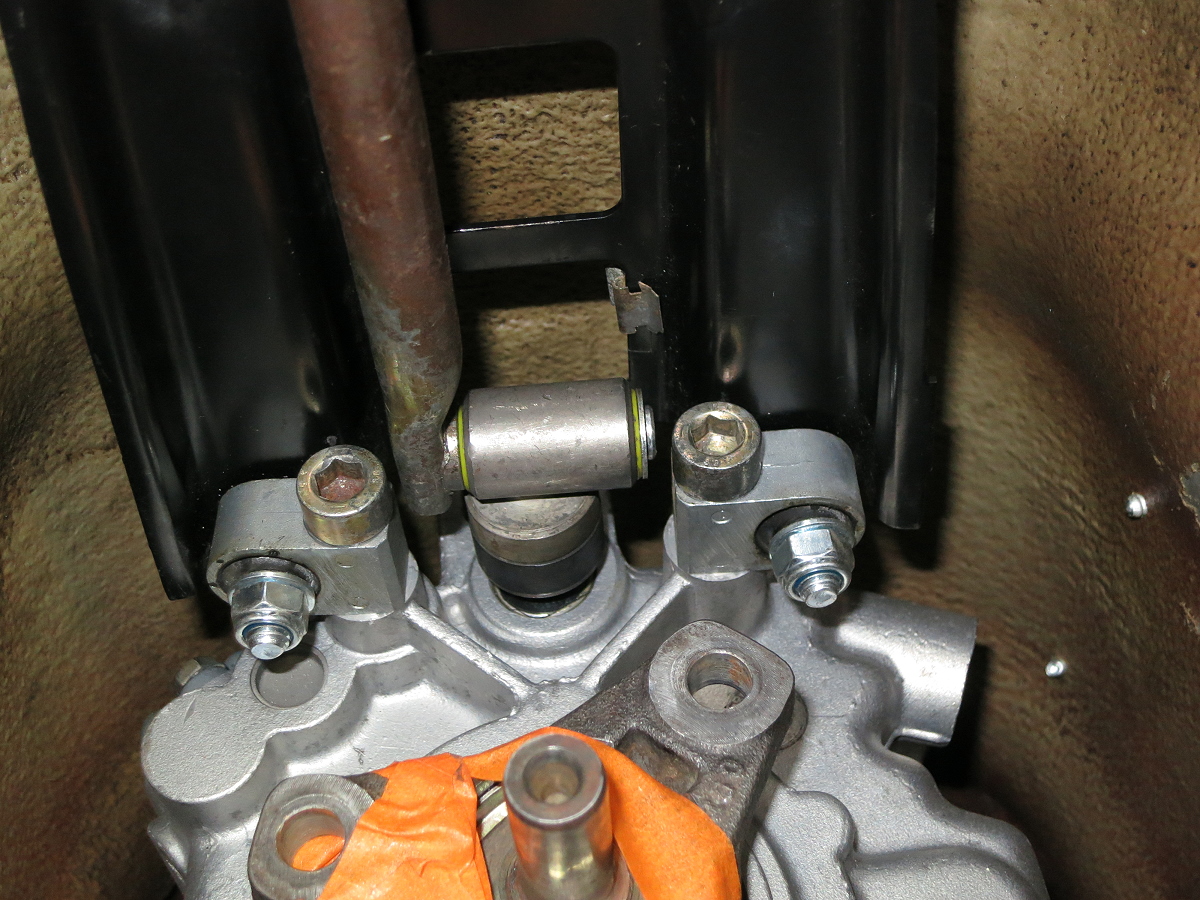

This is what you need to look for mounted on the top of the underside of the tunnel. This is for the aft mount.

Announcement

Collapse

No announcement yet.

Getrag 260 shifter linkage question

Collapse

X

-

Thanks!

I will take a closer look this weekend to see how it currently looks like on my E30 323i -85.

@Steve Corbett : So that thing in the picture is supposed to be bolted into the chassis?

And then you are supposed to bolt item #8 (see link below) into that thing in the picture?

Like this - or?

[item #8] => [thing in the picture] => [chassis]

If anyone have pictures of how it looks, please post!

I've only have how it looks like for an E34 535i with Getrag 260/6, and it looks different. Here you simply bolt item #8 directly into the chassis - see pictures below.

Comment

-

The mount on the car is spot welded in place. Then the shifter arm bearing, then the shifter arm. So visually the car mount will bolt up between part 8 and nut 9.sigpic

Steve Corbett

1983 528E Scrapped

1983 528E Sold

1984 745I

1984 325E - Sold

1989 325I Bronzit-Sold

1989 325I Zinno

1988 635CSI

Comment

-

Due to a numerous circumstances, background and conditions and requirements

I went for the solution to try to convert the new style gearbox into old style.

I compared and measured and realized this would be possible. The casting is

there, but it's not drilled and tipped. But there is one big drawback, the left

one is a through hole.

The right hole was no problem, I simply drilled it deep enough to be able to

tap it with a bottoming tap and still able to use the ordinary bolt.

Picture below shows that hole after drilling, but before tapping.

The left hole was more worrying.

I drilled just until it started to break through. Then I used huge

amount of really sticky grease and drilled a very short distance,

cleaned the drill, added new grease, drilled a very short distance,

cleaned the drill and so on.

Used the same procedure with the tap.

I was able to keep the metal chips into the gearbox to an absolute

minimum, but a few of them went probably into the gearbox.

However due to the reasons mentioned in the beginning this was

the most appropriate thing to do. Yeah, I have a magnetic drain

plug but no use for aluminium...

Nevertheless, the gearbox is now in place and the shifting

mechanism is in place exactly as before and works just as

before.

So problem solved! :-)

Comment

Comment