Metal working in the rain

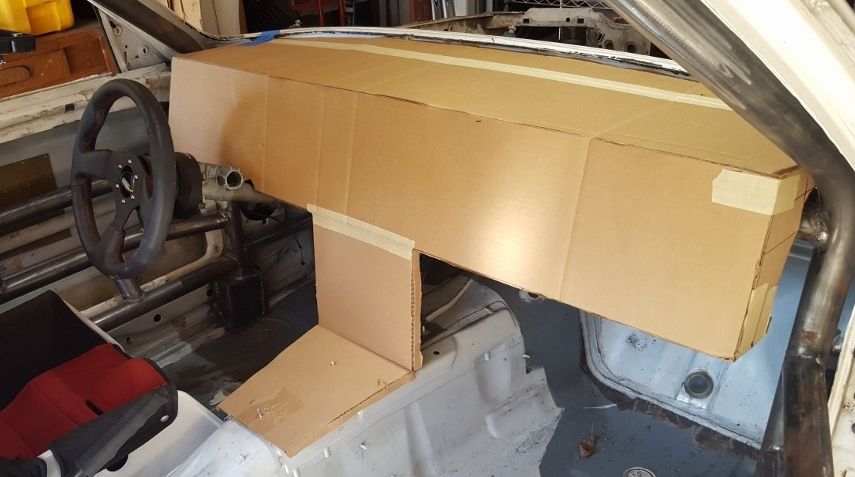

Getting started converting cardboard templates to metal parts. Here's the tool of choice: $40 electric shear from Harbor Freight. Forget the air nibblers. They are useless without a very serious air tank.

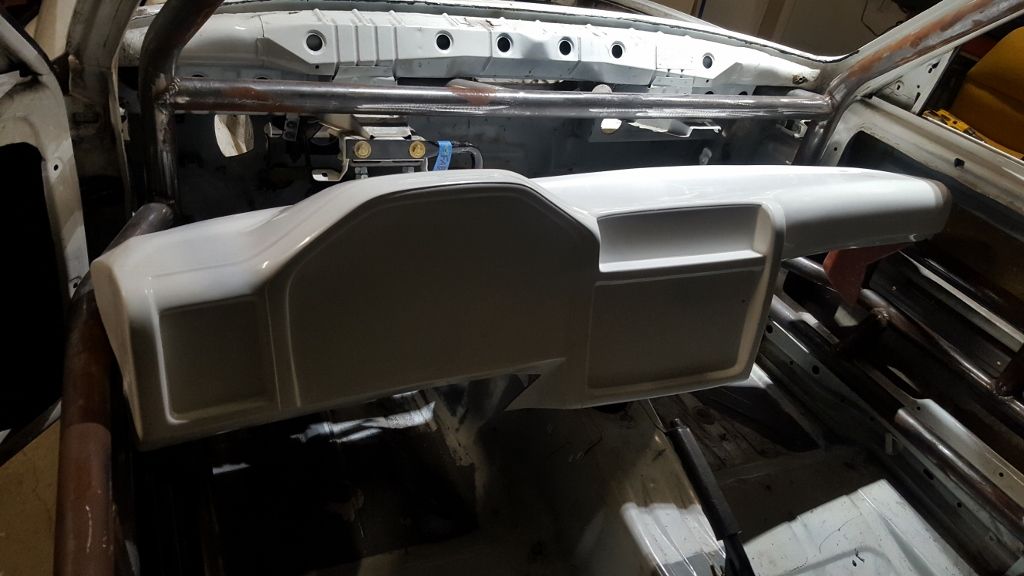

Here's the back deck taking shape. It conveniently started pouring rain.

Impressive results so far.

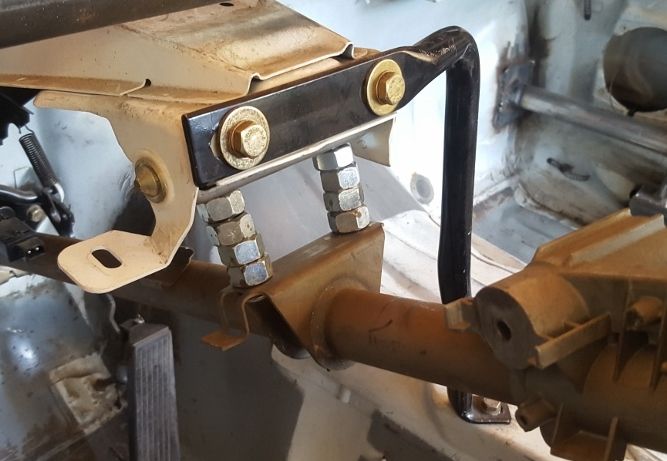

Forming the upper inside piece

Fits nicely

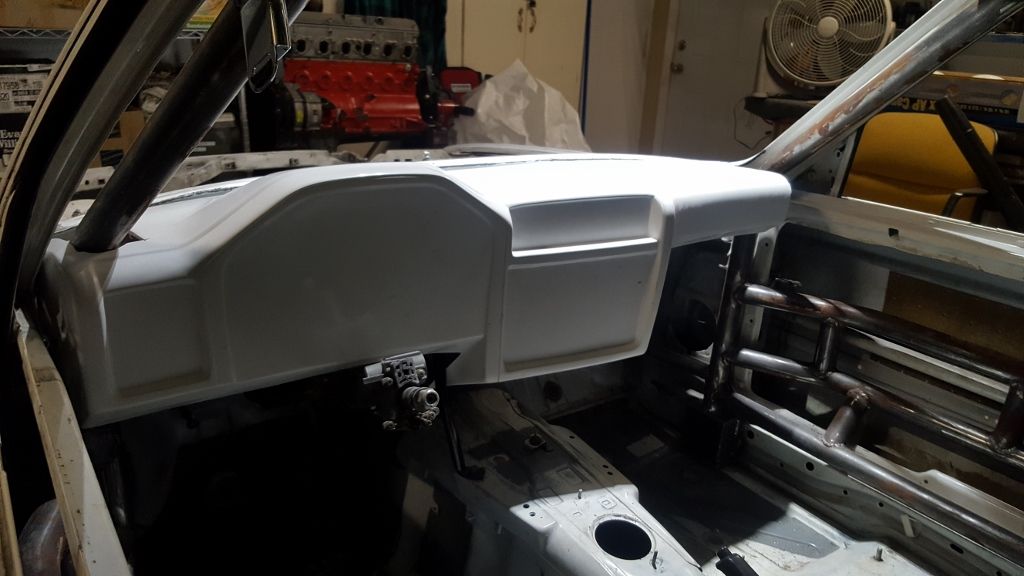

Forming the lower piece

Our ghetto metal break using 2x4s and clamps

Excellent results given the available tools. Needs a bit of trimming.

Final product looks great.

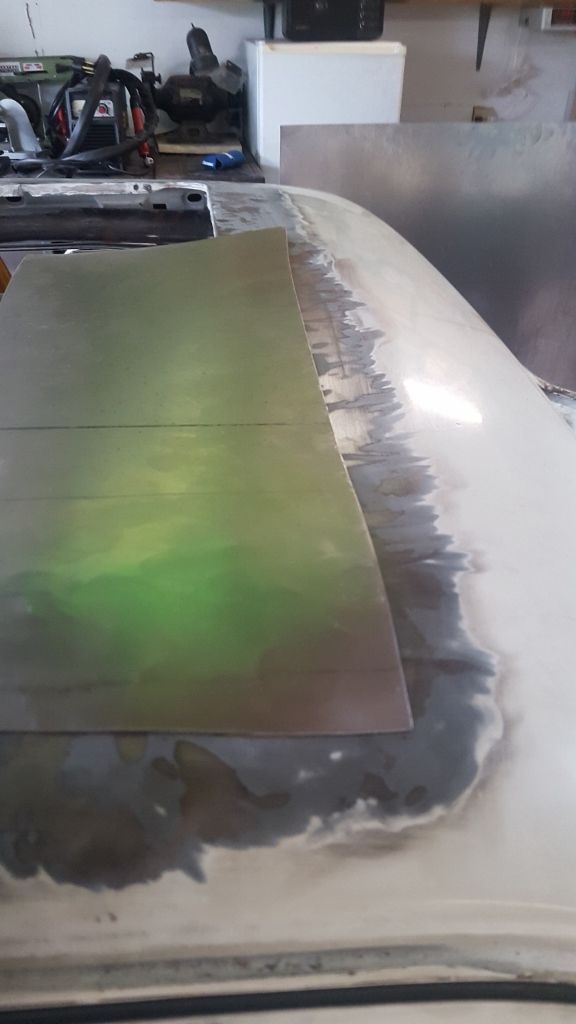

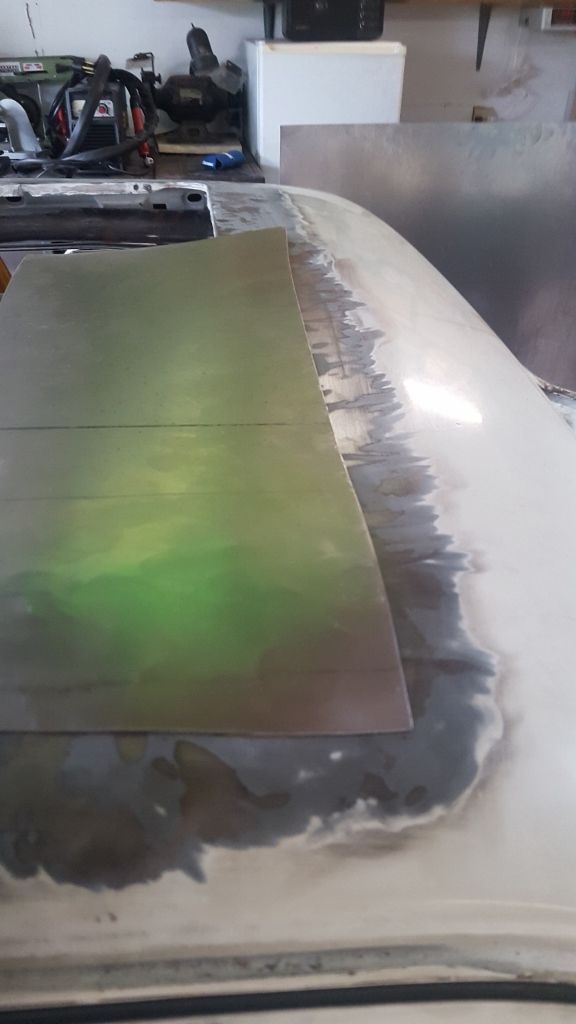

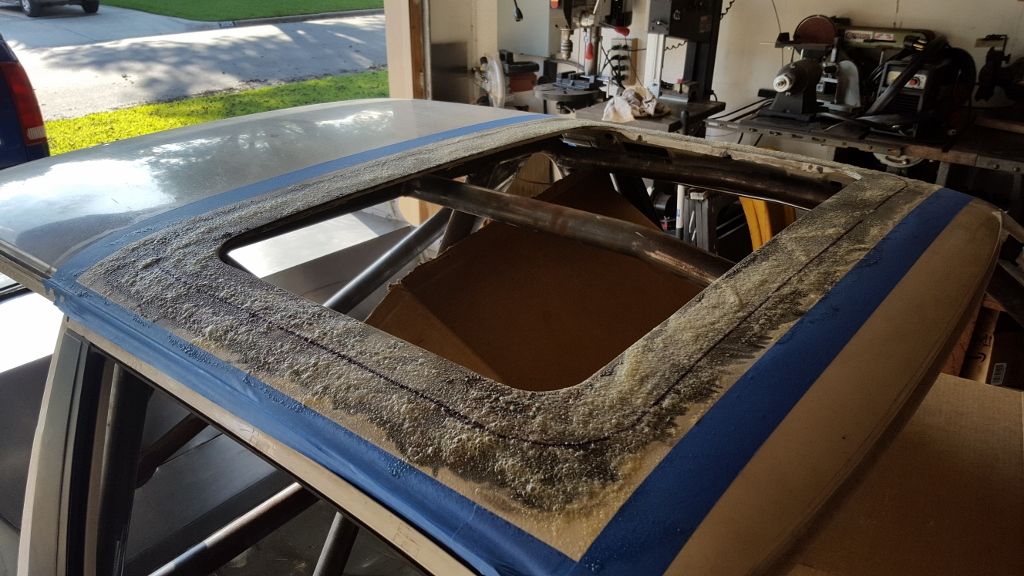

Cutting out the roof patch.

Practicing hammer shaping metal so it conforms to the roof

We used the compressor tank as a large radius bend press.

Here it is in place. Not bad quality. Definitely good enough for a race car.

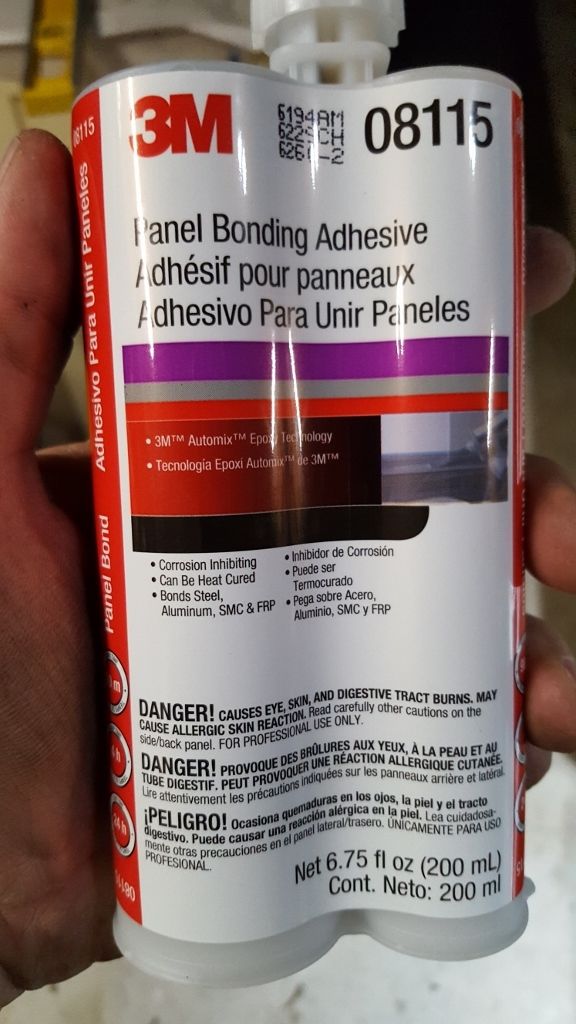

Metal prep, clamping, bonding and sheet metal screws next.

Getting started converting cardboard templates to metal parts. Here's the tool of choice: $40 electric shear from Harbor Freight. Forget the air nibblers. They are useless without a very serious air tank.

Here's the back deck taking shape. It conveniently started pouring rain.

Impressive results so far.

Forming the upper inside piece

Fits nicely

Forming the lower piece

Our ghetto metal break using 2x4s and clamps

Excellent results given the available tools. Needs a bit of trimming.

Final product looks great.

Cutting out the roof patch.

Practicing hammer shaping metal so it conforms to the roof

We used the compressor tank as a large radius bend press.

Here it is in place. Not bad quality. Definitely good enough for a race car.

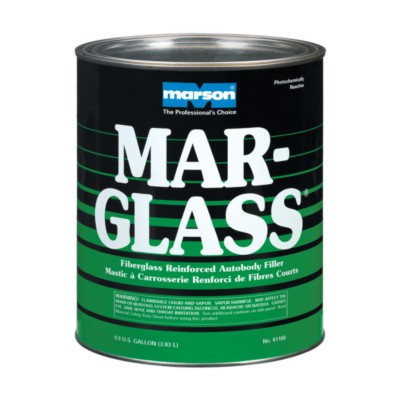

Metal prep, clamping, bonding and sheet metal screws next.

Comment