Started building a chop saw stand the other day. Thought I'd share some pics just in case someone else was planning on building one anytime soon. Cutting on the ground is hard on the back!

I cut a lot of 45*s and different angles, so I decided to make the top table rotate-able. I used four small steel casters and a 1/2" pin to keep it locked in position. It works surprisingly well.

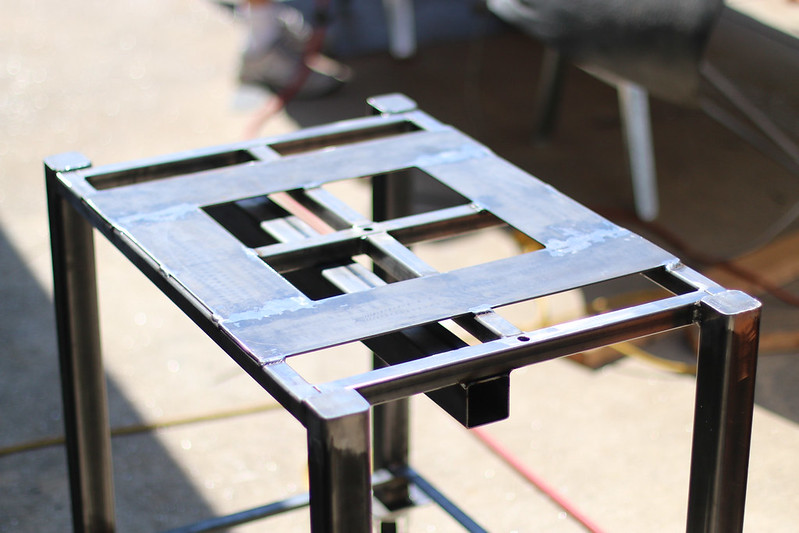

Here's the base all welded up.

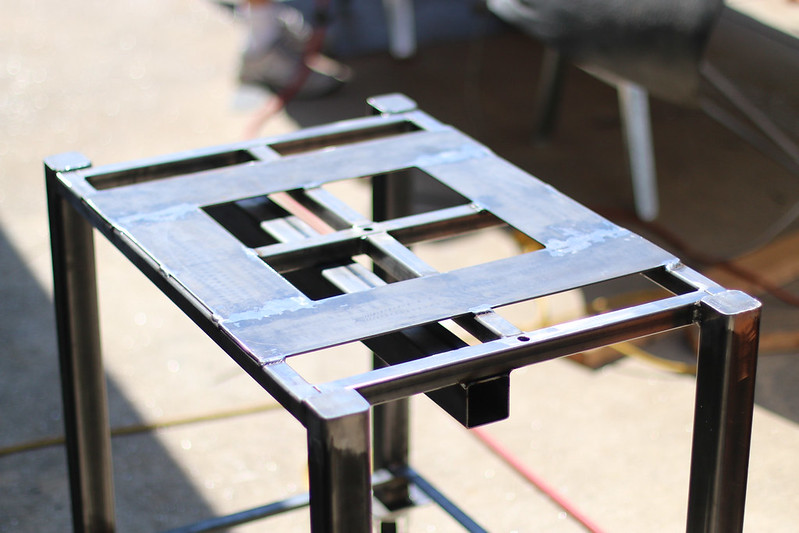

Here's the top table

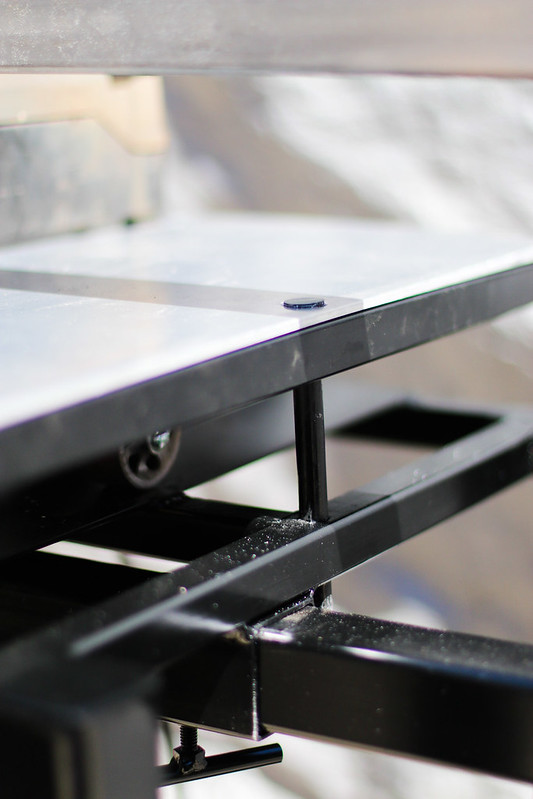

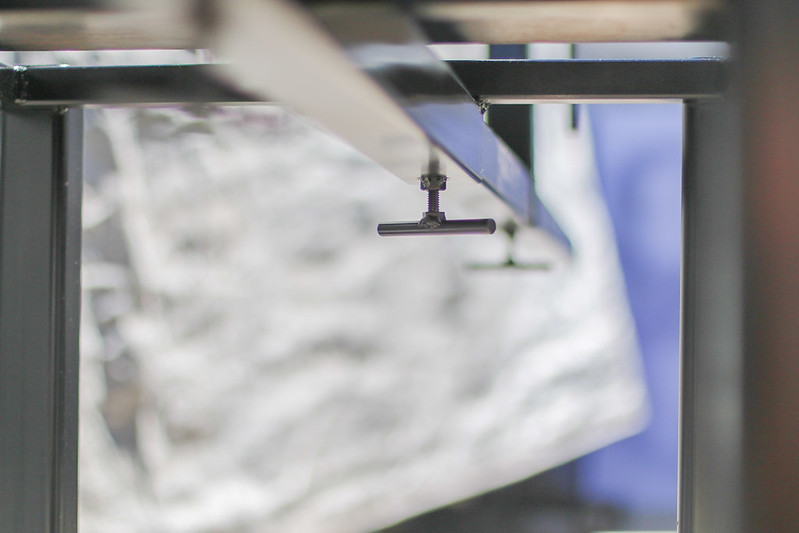

Here's what will guide the material

I plan on finishing it up in the next few days, just wanted to share what I have so far!

I cut a lot of 45*s and different angles, so I decided to make the top table rotate-able. I used four small steel casters and a 1/2" pin to keep it locked in position. It works surprisingly well.

Here's the base all welded up.

Here's the top table

Here's what will guide the material

I plan on finishing it up in the next few days, just wanted to share what I have so far!

Comment