Originally posted by dvallis

View Post

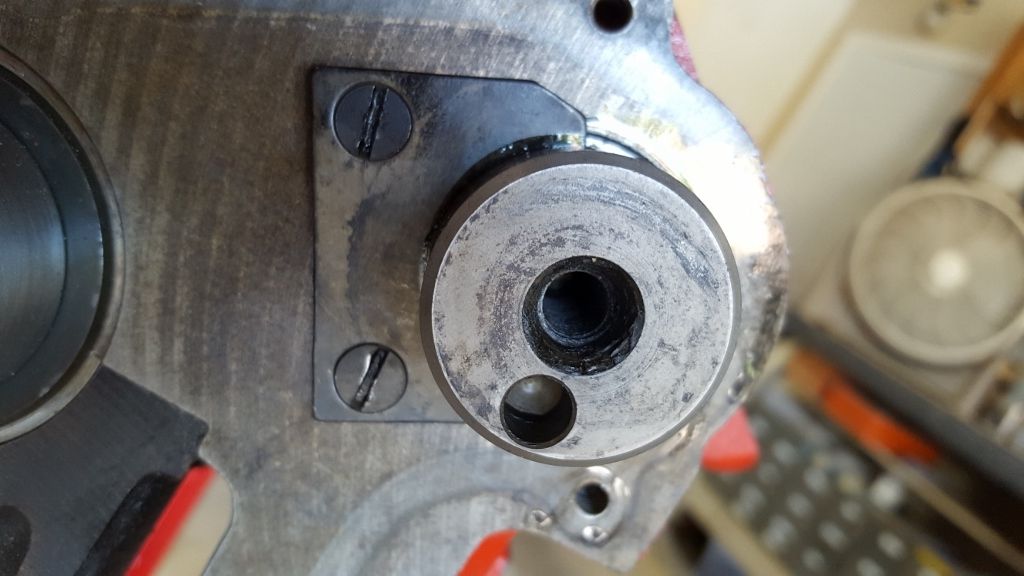

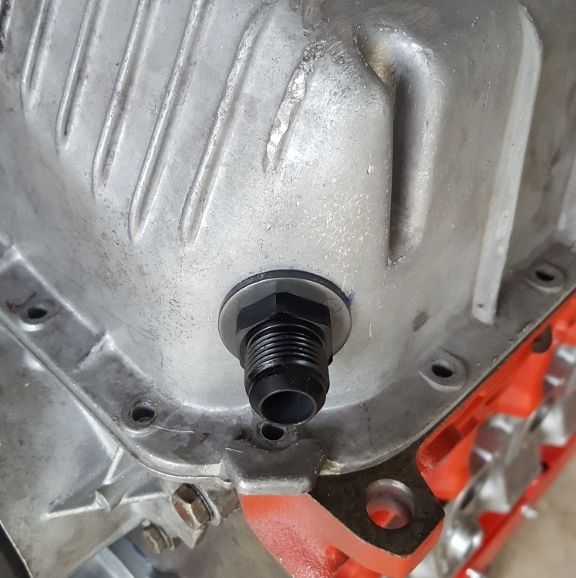

I did the same thing with my oil pump but I was wondering if there will be a noticeable difference because the hole that the pump sucks in from remains the same.

Sent from my iPhone using Tapatalk

Comment