Anyway, I received my Mercedes aux pump. It fits into my coffee mug and pumps a measured 1600 liters/hr. Dead silent.

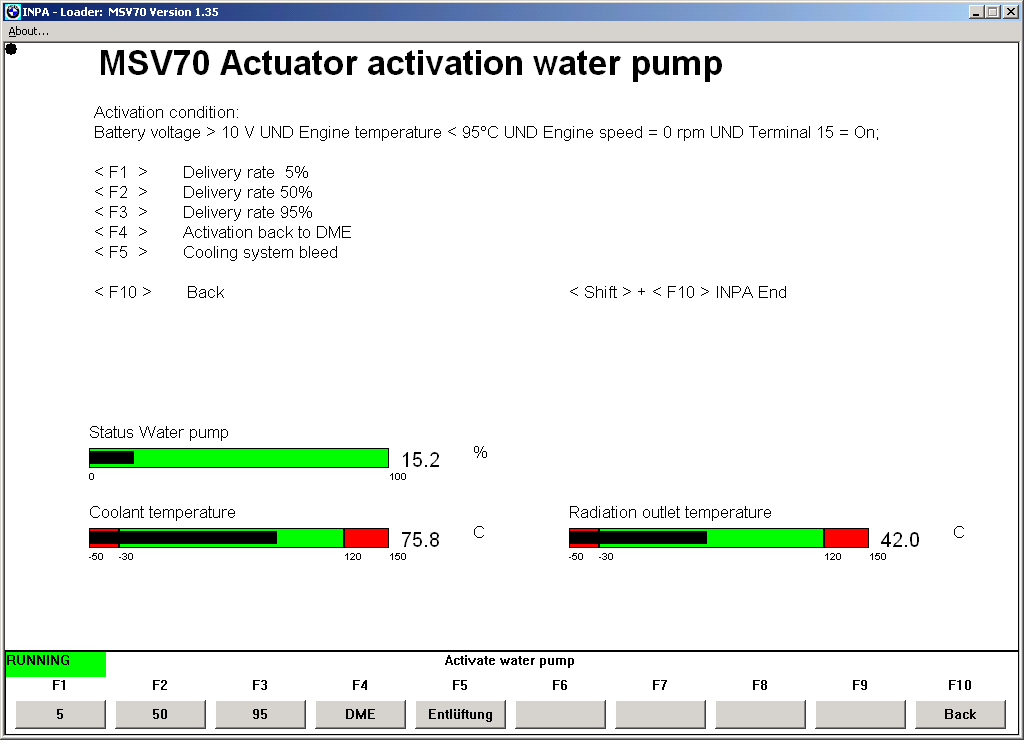

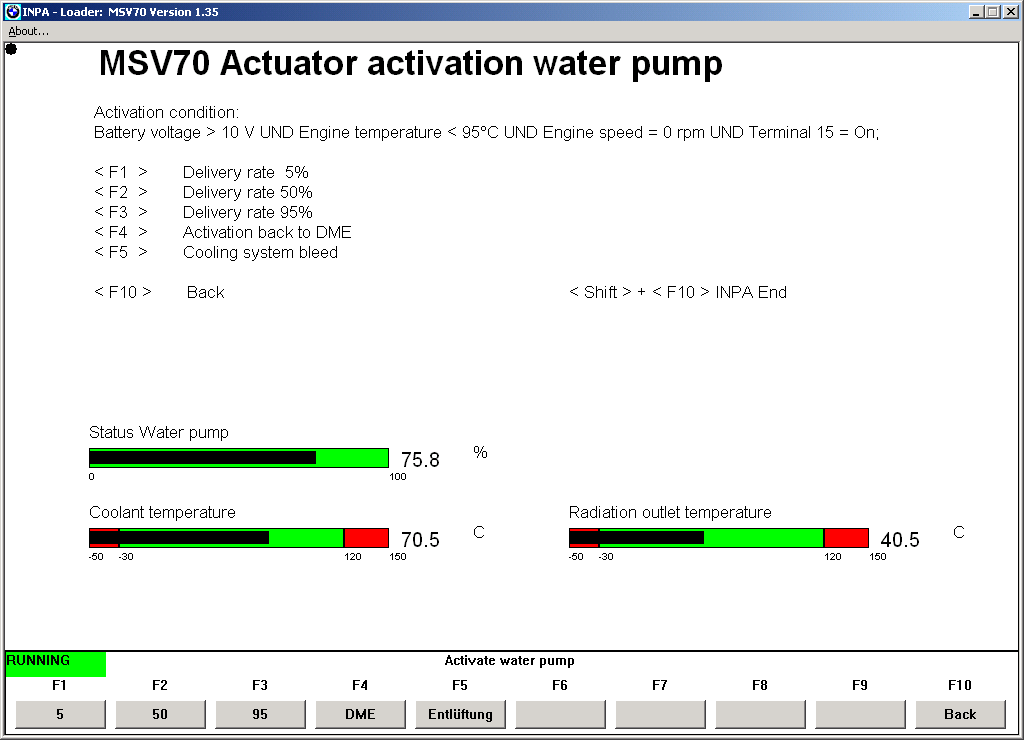

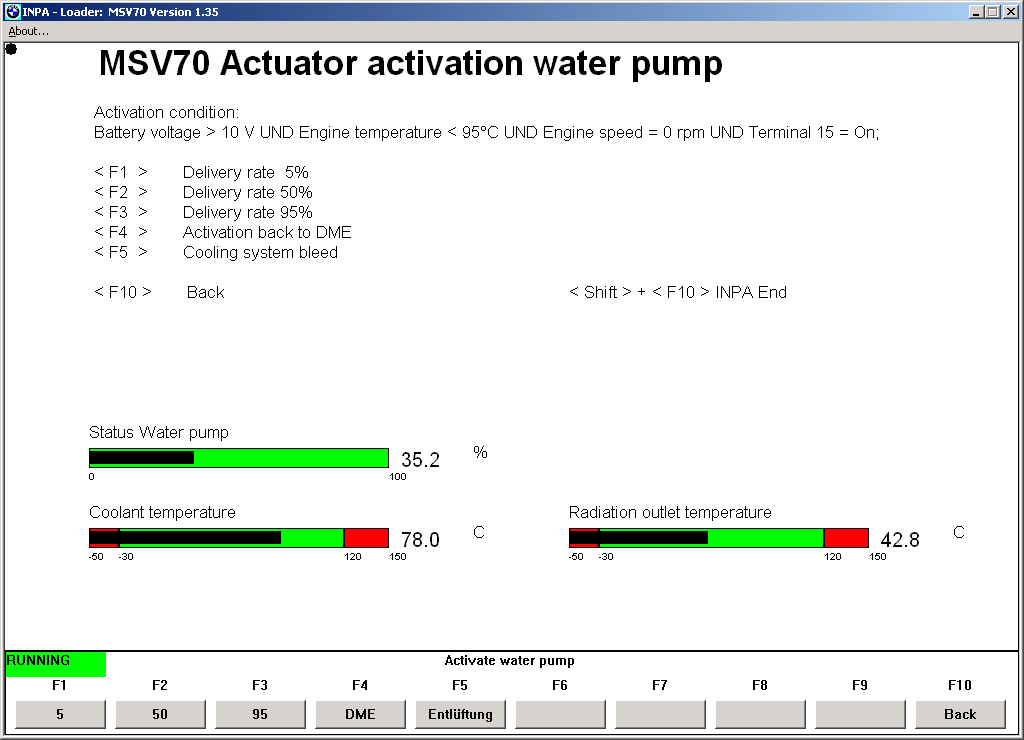

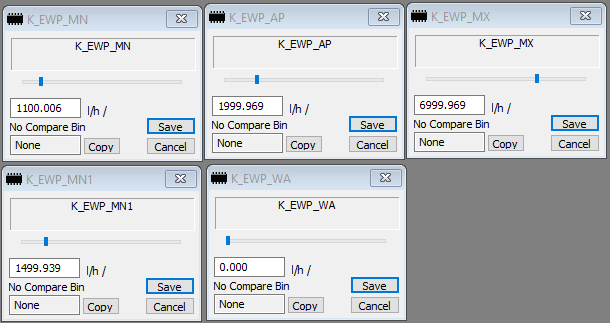

Here's the mind-blowing part. 1600 litres per hour is 23% of 7000 litres per hour, or the main coolant pump running at 23%. So, 2000 liters per hour will cover this pump and plenty for flow through the radiator.

It probably won't go in the car but the Koi love it!

Leave a comment: