I got the X3 rack fitted into my iX Toruing. Check out my thread in my signature to get some more info/pictures.

I still need to remove it one more time, when I rebuilt the rack the bushings I used were quite tight and I had to tap in the steering shaft in the housing.

I still have to original bushing that I plan to reinstall, this will hopefully solve some issues of slight binding I'm having near the center of the rack

Announcement

Collapse

No announcement yet.

ix quick ratio steering rack now available!

Collapse

X

-

This sounds promising. But I'm concerned about slop. If the racks they are using are not fully rebuilt and just resealed, you may end up with a big problem on your hands.

Also, it is required that the motor mounts be in PERFECT condition and that your ride height is stock. So if your motor mounts wear out or your springs start to sag you may end up banging things around.

These are my worries, anyway.

Has anybody installed this that can report back with their experience? Thanks in advance!

Leave a comment:

-

I've had the chance to measure both steering racks and the iX subframe.

After putting the measurement reports into Solidworks, I came to the following conclusion.

To get the X3 steering shaft/cylinder in the same position as the original iX steering rack, the X3 steering rack mounting points need 7,8mm removed.

When removing this amount from the mounting holes, there is even more clearance issues with this stump on the X3 rack and subframe.

I could mill a pocket to get clearance, the iX subframe has plenty of reinforcement ribs, so I think it shouldn't be a problem

I centered the rack from the inner holes of the rack, not sure how to explain this, but the plane/surface where the inner tie rod ball joint hits the rack. Somehow these pockets aren't the same depth, 18,7 and 22,5mm respectively.

New holes need to be drilled to mount the rack as well. 3mm more towards the rear and each hole 4mm more inward.

Now, to get the same bumpsteer as the original.

iX rack has 70,2mm travel/each side

X3 has 80,9mm travel/each side

Total length iX = 617mm ; total length X3 = 672.8mm)

So to get the same length, the X3 needs to have 27,9mm removed

Then, 80,9 - 27,9 = 53mm travel

-> 17,15mm less travel than the iX rack, only then you will get the same bumpsteer as original.

Question now, anyone that has an idea how much the 7,8mm height will have in bumpsteer? Should I just try and run the X3 rack without making any changes to it first and go from there.?

Cheers!

- Likes 1

Leave a comment:

-

This is awesome. I've been looking into this for years and never got anywhere. IMO, $1200 is well worth it when considering what a new ix rack must cost now.

- Likes 1

Leave a comment:

-

You forgot the steering linkage if you don't have an airbag car, so that's $1400+$250. Not sure where I got $1825. But it would be $1650+shipping now. Which is probably another $150.

- Likes 1

Leave a comment:

-

Heard back from Kent today on this topic. "Our racks are resealed where needed, but are not completely remanufactured. They carry a 2 year warranty against leaks." So take that for what it's worth.Originally posted by madman23 View PostThis is awesome. Definitely some great work!!! Am I right to assume the rack is rebuilt?

Also the racks are selling for $1400 + shipping (not $1825 as previously mentioned here). You get $200 back if you return a core to them, although shipping likely eats a lot of that up as well, depending on where you're located.

Leave a comment:

-

Super cool and something I've been wanting in my iX for a while now. Will be following along closely, good luck!

Leave a comment:

-

I'm no steering guru so that's why I'm posting the info I could gather on there.Originally posted by erwendell View PostDoesn't the rack then need to be shortened by 29mm on each side? I thought that in order to maintain the designed bump steer and Ackerman characteristics the tie rod inner to outer ball joint center lengths need to be the same as before. Using shorter tie rods to compensate for a longer rack changes both pivot to pivot length and the angle.

to hopefully figure this out with a couple of you guys!

I'll look further into this topic

Leave a comment:

-

Doesn't the rack then need to be shortened by 29mm on each side? I thought that in order to maintain the designed bump steer and Ackerman characteristics the tie rod inner to outer ball joint center lengths need to be the same as before. Using shorter tie rods to compensate for a longer rack changes both pivot to pivot length and the angle.

- Likes 1

Leave a comment:

-

Little update for you guys,

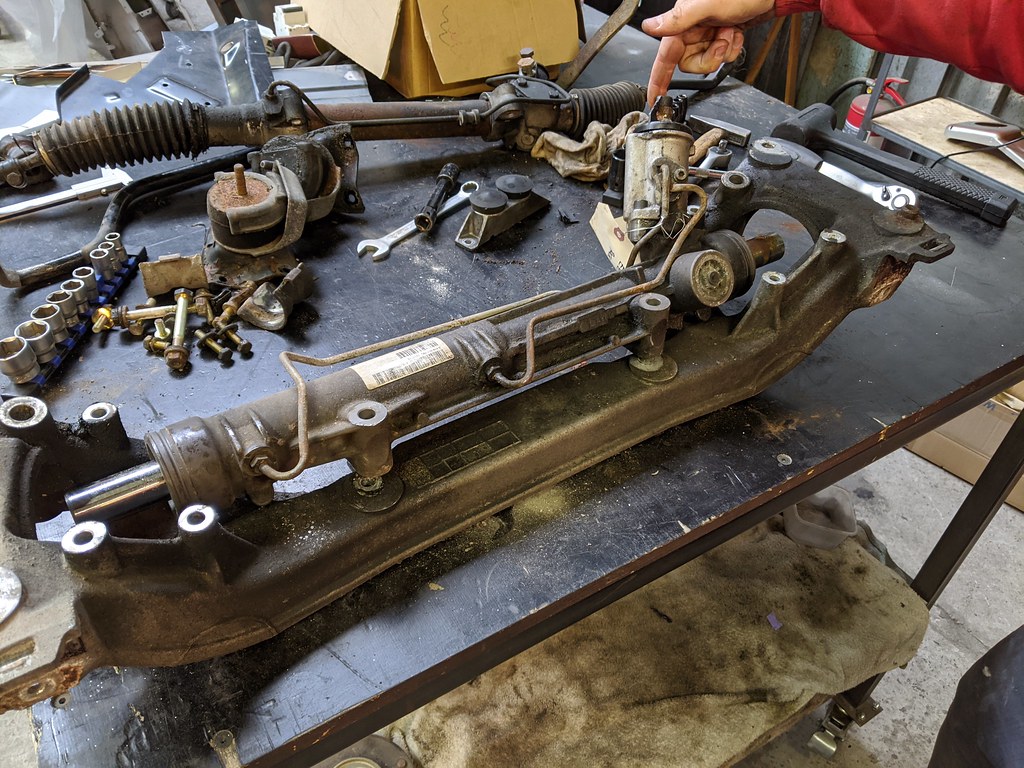

As some of you might have seen on my build thread, I got myself a spare original iX rack, front iX subframe and of course the X3 steering rack.

I've gone ahead and cleaned everything, took some measurements and quickly put them into solidworks. To finally put them onto each other to check the differences.

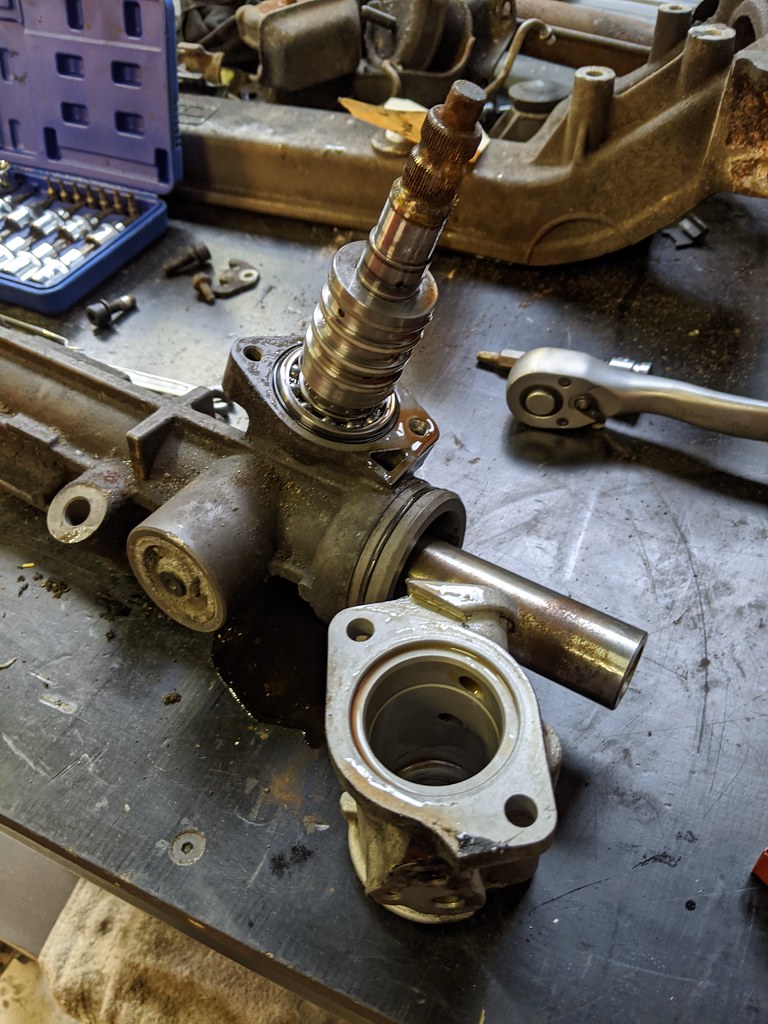

It is indeed possilble to rotate the upper housing to get the hydraulic lines facing the right way

Now for the measurements, this is what I got. Do note, I used some square/rectangular box tubing to reference off so take +/-1mm into account...

Blue sketch lines are the X3 steering rack, grey is the original iX rack

1)The X3 rack has 10mm more travel. To get the same kind of travel as the iX a simple spacer will be needed as far as I understand so the tie rod stop agains this spacer instead of the rack itself.

2) Since the rack is +/-29mm longer on each side, there is a need for shorther tie rods like mentioned above

3) Original bolt holes will be needed to weld shut and re drilled to account for the differences

4) This might be the hardest part to figure out, the machined faces where the X3 steering rack sits onto the subframe are 6.5mm deeper from the centerline than the iX rack. It's possible to solve this by removing 6.5mm from the X3 rack but since the overall diameter of the rack is already quite a bit bigger, there is even more risk to run into clearancing problems.

I would like to put both racks and the subframe onto our CMM. I do know we are planning of purchasing a 3D laser/scanner system at work, which would make this even better to figure out. But I have currenlty no idea on when this would get purchased.

- Likes 3

Leave a comment:

-

I would agree, with your logic, and if it were a grand it’d be a totally different story, but it’s double that with shipping.Originally posted by E30andy View Post

I look at it like this.....most of us dont have a monthly car payment since we are driving old cars that are relatively cheap (when compared to a new car). Therefore, in that context, putting out $1k dollars for something that improves performance and probably resale value, spread out over the life of the car becomes pretty cheap.

Most of us paid less than the rack swap for our cars haha.

- Likes 1

Leave a comment:

-

I look at it like this.....most of us dont have a monthly car payment since we are driving old cars that are relatively cheap (when compared to a new car). Therefore, in that context, putting out $1k dollars for something that improves performance and probably resale value, spread out over the life of the car becomes pretty cheap.Originally posted by madman23 View PostThis is the huge issue right here. High price when someone build something cool for the IX community, yet so expensive E30 guys don't want to buy it.

Leave a comment:

Leave a comment: