Announcement

Collapse

No announcement yet.

M42 rebuild

Collapse

X

-

The oil return valve was implemented on the E36 if I remember correctly. Occasionally the oil will drain down from some lifters, causing a noisy start for a few seconds as they pump back up. Also, I do not know if the oil return parts will fit into the E30 block or not. It is not something that I consider critical to have, but if you get the parts and they happen to fit into the E30 block, that would be good to know.

Leave a comment:

-

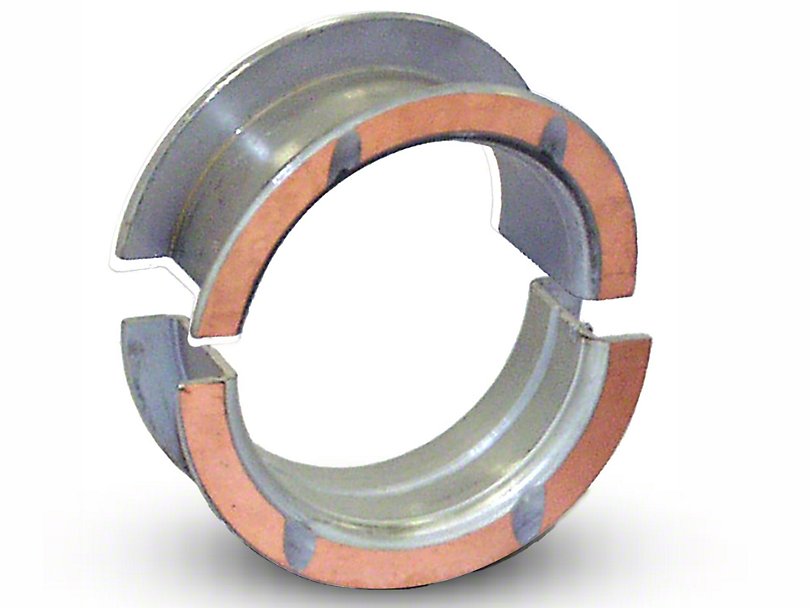

yea, I looked online and all have 360° trust bearing, but what about 360° lubrication?Originally posted by econti View PostSmall necro - but I believe all replacement bearings now feature 360 degree thrust.

Moreover, while preparing the list of parts to order I noticed mine didn't come with the check valve on the head for oil return. Is it normal? should I buy it?

By the way, I ended up buying a used crankshaft which is in way better shape.

Thanks again for the support. It is really appreciated.

Leave a comment:

-

Small necro - but I believe all replacement bearings now feature 360 degree thrust.

Leave a comment:

-

Have to admit, I've never had to take the bottom of either M42 apart- try

the M42club boards, as I remember a few pretty involved discussions.

And I have learned from the M10 to not be afraid at all to drill holes in bearing shells.

Just to be careful when actually doing it!

hth

t

Leave a comment:

-

Yes, I will definitely upgrade to 360° lubrication and 360° trust bearing. By the way, do you know which bearings are compatible or need just little machining? The thrust bearing seems to fit the other half, just need a little machining on the locating tab, but it has the two oil holes that I don't want in the upper half. Do you know which model is compatible? I still have to look in details.

Concerning the crankshaft, I will try to see how much it costs and if I can find a used one in better shape for the same or slightly higher price. If not I might use the one I already have. As you said the thrust bearing is not required to be 100% spotless to work, since it operates just when clutch is depressed.

Thanks again for the support and the awesome community.

Leave a comment:

-

Looks like it has been detonating.I've seen better looking pistons

The bearing has thrust surfaces on shell halves.what does a full thrust bearing look like?

If the wear can be polished or ground oversize successfully,

you'll be ok. And 'successfully' doesn't mean perfect, just

good enough to bear thrust and not allow movement.

Unlike the main surfaces, you can get away with some residual damage.

t

Leave a comment:

-

That helps clear it up. And regarding the design... were talking about the same engineers that put a weepy/leaky power steering reservoir RIGHT OVER an alternator on half their engines.

Leave a comment:

-

Instead of having a full oil gallery (groove) in just the lower half you have a contiguous oil gallery.

No one is quite sure why BMW originally specified a 180 degree oiling bearing instead of a full shell. It may have had to do with trying out a new methodology in engine building, or perhaps they thought that sufficient oil would reach the upper half (which it does under normal conditions), or perhaps they simply did not care about longevity after 5-10 years.

Leave a comment:

-

For the uninitiated and under-informed, exactly what does a full thrust bearing look like? I heard the M50 bearings can fit the M42 and were not half shell but they looked identical. Either I was mistaken or I have no idea what half or full shell means.

Leave a comment:

-

The thrust bearing setup on the E30 M42 is one of the known bad design choices. As you have found, they only used a half-shell for the thrust surface. As a consequence, crankshaft axial runout can become severe. A main cause of this is starting the engine with the clutch pedal pressed down...zero oil pressure and probably 1kN of axial force on the thrust surface. No good! Since there is no requirement to start this car with the clutch down, it is easy to avoid in the future.

If the thrust surface on the crank has deep grooves worn into it or it is severely worn such that the journal with is much too large, then the crank is probably not worth trying to fix.

Look into installing two thrust bearing halves so that you have the full 360 degrees of bearing surface. I cannot recall if any machining is required, but I think that it was a very straightforward modification (you could test fit the old one onto the other side).

The cylinder walls look OK, and if you had a shop do a light re-hone they should be good. You may need the next size up of rings, but that is for you to check with a mechanic.

Other than that, it looks like you are making good progress. Don't forget to get the newer timing case-to-block gasket to go with the E36 M42 timing case. It is not the same as the E30 one. Also pull the oil pressure relief valve assembly out of the timing case and inspect it. The original design was later updated to prevent it from seizing open, causing oil pressure loss. It is easy and relatively inexpensive to do the update, involving parts 5-8.

Check the cylinder head for cracks, mainly between the exhaust valves of cylinders 2 & 3. It has been known to occur. If there are some small ones forming that have not yet fully failed, a competent welding shop should be able to fix those.

Leave a comment:

-

Final disassemble and doubts:

yesterday I completed the removal of oil pump, pan, pistons and crankshaft.

First, a detail of the cams and the bearing surface

Oil pans removed. No loose pump bolts

Sprocket removal. Had some troubles since the key is slightly damaged.

Oil pump housing removed

Some oxidation on the crank

Piston and cylinder

Worst cylinder

Crank came out easily

Bearings need to be changed

Strange abrasion on one bearing let me wonder about the trust bearing, which resulted to be severely consumed

Unfortunately also the crank resulted damaged, with a play of approximately 1.5mm

I will bring the parts to my mechanic and ask about what's better to do.

I wanted to ask you what do you think from the pictures and if the crank is to be scrapped, as I think.

In that case I might consider a stroker with M47d crank.

Thanks for your support and suggestions.

Cheers,

Luca

Leave a comment:

-

Updates:

Yesterday I have gone on with disassembly.

First of all, I have removed the head cover

I have removed the upper chain guide to remove the timing gears

Cams don't look to bad or scratched, according to me

Removed water thermostat housing and upper cover

I removed the cams with the method explained on Pelican parts. For the wondering, it is: https://www.pelicanparts.com/BMW/tec...ft-removal.htm

After removing the trays

Without the head

I've seen better looking pistons

Removed lower case and water pump. For those wondering there are two threaded holes where to screw the bolts in to remove the water pump. It took me forever before I realized it

All the parts stored

As suggested from you, I will upgrade to m42 e36 lower timing case, if I can find one.

The next steps will be removing oil filter housing an pump, oil pans and see internal conditions.

Thanks for your help and suggestion. Hope it is helpful or at least interesting

Leave a comment:

-

I would actually recommend getting rid of the sprocket, despite the cost increase of the newer timing case (I have bought used ones for ~$70). Other than that, rebuilding it should not really cost more than the M42 case. The later case uses a different gasket between itself and the block (don't forget this!), but it is about the same price.

The only advantage of the M44 case is that the oil pump rotors are 20% thicker, meaning 20% more flow. This can be advantageous on a built up M42 with higher compression and hot cams where pressures and speeds are more severe between moving parts.

Leave a comment:

-

I think youre right in that there isnt much advantage to using the M44... I dont know where its coming from then.

I also thought it was any e36 M42, but it looks like youre right, the plastic rail to replace the deflection wheel started in 94.

Honestly though, I would rather spend my money on getting new pieces for the rail than on a timing case unless the parts fell on my lap. The deflection wheel cant be that bad right?

We're talking about $300+ in parts here for the rails alone, which absolutely should be replaced.

edit: The killer is the guide rail, pn 11311247483. I was lucky to find one for sale for $75 from someone who didnt understand that you can fit the M44 guide rail in to the E36 (and E30?) timing case with some hardware replacement.Last edited by jaredmac11; 11-07-2018, 10:27 AM.

Leave a comment:

Leave a comment: