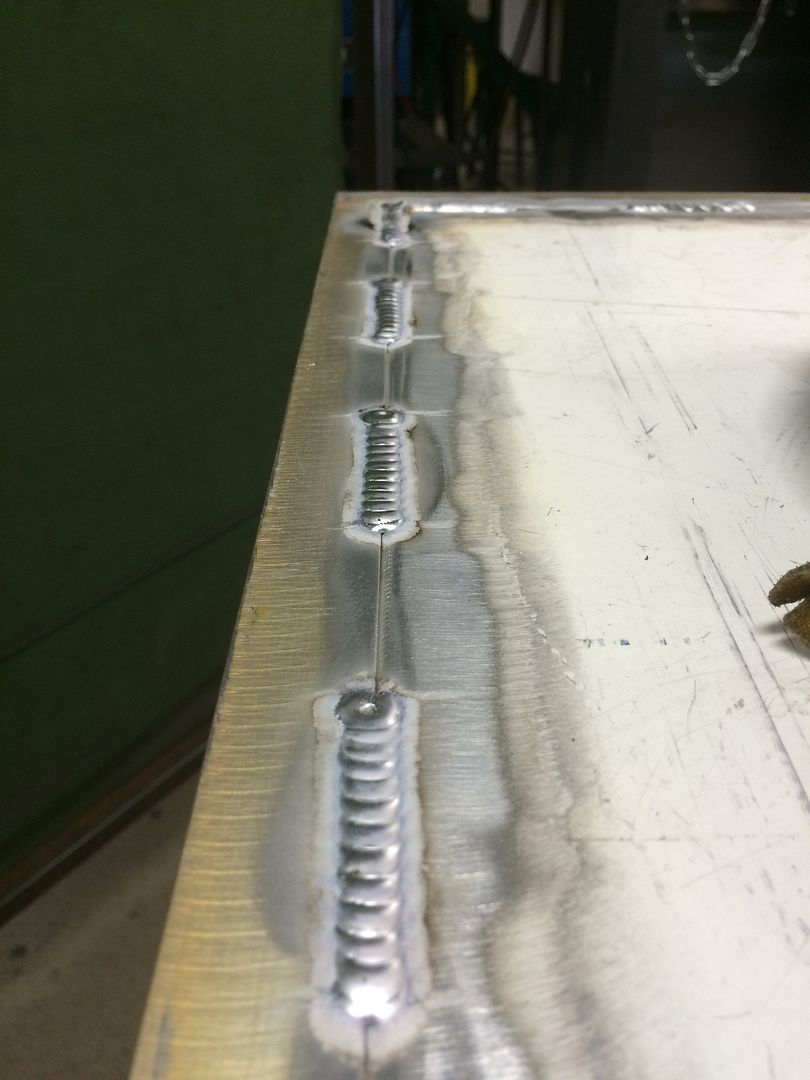

I think I was using R45 rod, but got tons and tons of contamination. At one point I could see a flakey goopey substance being pushed out of the puddle... really weird. When I would dip, it would flake up and move forward a bit. This last little project just confirms that I want/need a home machine with all my own rod/materials. Jumping in on whatever is available is a good skill to learn, but I want to practice, practice, practice.

Anyways, some pictars.

coil overs by ericandshovin, on Flickr

coil overs by ericandshovin, on Flickr DSC_5377 by ericandshovin, on Flickr

DSC_5377 by ericandshovin, on Flickrfinished product... you can clearly see when the puddle was flowing nicely, and when it was mad and spitting.

perch by ericandshovin, on Flickr

perch by ericandshovin, on Flickr

Aluminum foil was not as good as thought it would be...

Aluminum foil was not as good as thought it would be...

Leave a comment: