Originally posted by AWDBOB

View Post

Announcement

Collapse

No announcement yet.

The Journey of Linda and Friends - the M20b31 Lives

Collapse

X

-

The way they removed material get the the correct dish volume is not how it should be done. They should have mirrored the chamber89 E30 325is Lachs Silber - currently M20B31, M20B33 in the works, stroked to the hilt...

new build thread http://www.r3vlimited.com/board/showthread.php?t=317505

-

Thanks, man!! It has been a long time coming, but I think the patience has paid off. I will certainly let you know how the car feels.Originally posted by e30austin View Posthell yes!!!! excited for you :)

you will have to let me know what you think of it. i am considering building an engine for my cabrio, eventually...

I still have a PNW road trip in me with this car, so there’s a large possibility you’ll get to take it for a spin sometime!

Thanks!! Hopefully I will be able to actually deliver something this time around, this thread has been a many year journey of me losing patience and changing my mind.Originally posted by rzerob View PostGlad to see things worked out for you Bob.

I don’t think it’ll be too troublesome since I’m not using an 885. You think it’ll cause detonation issues or something?Originally posted by digger View Post

The way they removed material get the the correct dish volume is not how it should be done. They should have mirrored the chamber

Comment

-

idk, it just doesn't have the same amount of squish area that it could have89 E30 325is Lachs Silber - currently M20B31, M20B33 in the works, stroked to the hilt...

new build thread http://www.r3vlimited.com/board/showthread.php?t=317505

Comment

-

To my understanding they are steam holes- and I’ve never seen a 731 head with those holes present.Originally posted by ForcedFirebird View PostDid someone weld the oil supply holes closed on that 731? Those center holes are for pressurized oil supply to the valve train.

The early m20b20 and m20b23 blocks didn’t have those steam holes, and this head came from one of those engines. I could be wrong, however.

anotha one:

https://rover.ebay.com/rover/0/0/0?m...2F183347545010Last edited by AWDBOB; 06-15-2020, 07:14 AM.

Comment

-

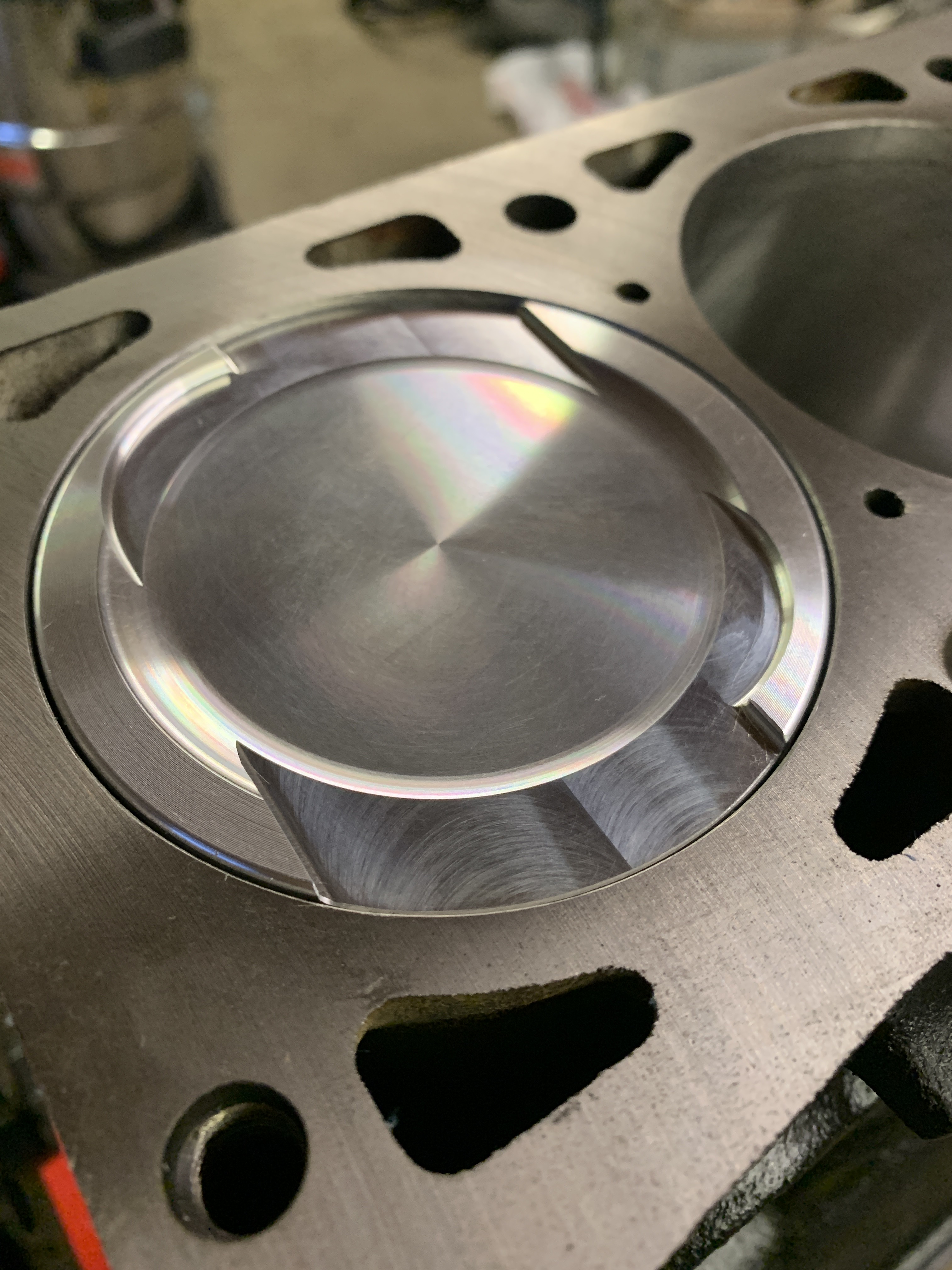

a day late and some squish area shortOriginally posted by digger View Postidk, it just doesn't have the same amount of squish area that it could have

also, digger- I know you understand this far better than I, but to my understanding, that squish area in flat top configuration is more about creating turbulence on the sides of the piston, ie, smaller part of the chamber, to squish energy into the center of the chamber. So taking that into consideration, it appears that concept was applied to these pistons seeing as the edges are raised where they would meet the smallest point in the chamber, pushing turbulence to the center of the chamber.

the offset dome stuff is an easier picture to paint- with the flat top configuration, I looked at the pistons with the above in mind and they didn’t seem too bad.Last edited by AWDBOB; 06-15-2020, 07:37 AM.

Comment

-

You're right, I was having a brain fart, the one center hole provides oil pressure next to the head bolt, but it is odd the 731 doesn't have those holes, 200's have them. I have a 731 head here, but it's still attached to the block, not so easy to look at that one just yet. :P

Squish is a band around the perimeter of the piston that nearly contacts the head in running conditions (.040" is generally accepted for rod stretch). When the piston approaches the head, that squish band forces the mixture towards the spark plug. With those pistons notched the way they are, that high pressure band is going to be forced against the head gasket fire ring on those opposing ends.

Comment

-

Ah, that makes sense. So the questionable area is where there is no ridge on the two sides, rather than the raised areas.Originally posted by ForcedFirebird View PostYou're right, I was having a brain fart, the one center hole provides oil pressure next to the head bolt, but it is odd the 731 doesn't have those holes, 200's have them. I have a 731 head here, but it's still attached to the block, not so easy to look at that one just yet. :P

Squish is a band around the perimeter of the piston that nearly contacts the head in running conditions (.040" is generally accepted for rod stretch). When the piston approaches the head, that squish band forces the mixture towards the spark plug. With those pistons notched the way they are, that high pressure band is going to be forced against the head gasket fire ring on those opposing ends.

Now that I research other pistons I see that the edge runs all of the way around.

I can’t imagine this will hurt power more too much, though. Most of my reading pointed at a 5% variance which I can live with.

Comment

-

the squish area on 200 and 731 is the surface bounded by the two red loops (the outer loop is the D86mm or bore and the inner loop is the chamber) the piston needs to be perfectly flat in the corresponding areas to maximise squish which means the two surfaces will then come within around 0.035" and 0.045" (parallel seperation) of each other to squeeze the air increasing the turbelunce speed in the chamber and moving the charge towards the spark plug. Its no coincidence the squish bad is the farthest / opposite region from the plug.Originally posted by AWDBOB View Post

a day late and some squish area short

also, digger- I know you understand this far better than I, but to my understanding, that squish area in flat top configuration is more about creating turbulence on the sides of the piston, ie, smaller part of the chamber, to squish energy into the center of the chamber. So taking that into consideration, it appears that concept was applied to these pistons seeing as the edges are raised where they would meet the smallest point in the chamber, pushing turbulence to the center of the chamber.

the offset dome stuff is an easier picture to paint- with the flat top configuration, I looked at the pistons with the above in mind and they didn’t seem too bad.

89 E30 325is Lachs Silber - currently M20B31, M20B33 in the works, stroked to the hilt...

89 E30 325is Lachs Silber - currently M20B31, M20B33 in the works, stroked to the hilt...

new build thread http://www.r3vlimited.com/board/showthread.php?t=317505

Comment

-

Yeah, that makes perfect sense. I should’ve had you design my pistons! Not sure why they didn’t carry that ridge all of the way around, or like you said, mirror the chamber. Oh well, not much I can do at this point hahaOriginally posted by digger View Post

the squish area on 200 and 731 is the surface bounded by the two red loops (the outer loop is the D86mm or bore and the inner loop is the chamber) the piston needs to be perfectly flat in the corresponding areas to maximise squish which means the two surfaces will then come within around 0.035" and 0.045" (parallel seperation) of each other to squeeze the air increasing the turbelunce speed in the chamber and moving the charge towards the spark plug. Its no coincidence the squish bad is the farthest / opposite region from the plug.

Comment

-

its a problem with the aftermarket piston industry, the designer just cares that the cc are what it needs to be and the valve reliefs are there. Very little thought is given to the actual combustion behavior. Some give the option of sending in a mould of the chamber but thats normally to get the dome to match the chamber (not a dish) and thats to get the CR higher.89 E30 325is Lachs Silber - currently M20B31, M20B33 in the works, stroked to the hilt...

new build thread http://www.r3vlimited.com/board/showthread.php?t=317505

Comment

-

The reason I went with TEP was because they claimed to have molds of the chambers they used to design the pistons, and that clearly didn’t happen- womp womp.Originally posted by digger View Postits a problem with the aftermarket piston industry, the designer just cares that the cc are what it needs to be and the valve reliefs are there. Very little thought is given to the actual combustion behavior. Some give the option of sending in a mould of the chamber but thats normally to get the dome to match the chamber (not a dish) and thats to get the CR higher.

Comment

-

Yeah for the 885 maybe as they are one of the few that do the OE dome offset dish b2589 E30 325is Lachs Silber - currently M20B31, M20B33 in the works, stroked to the hilt...

new build thread http://www.r3vlimited.com/board/showthread.php?t=317505

Comment

-

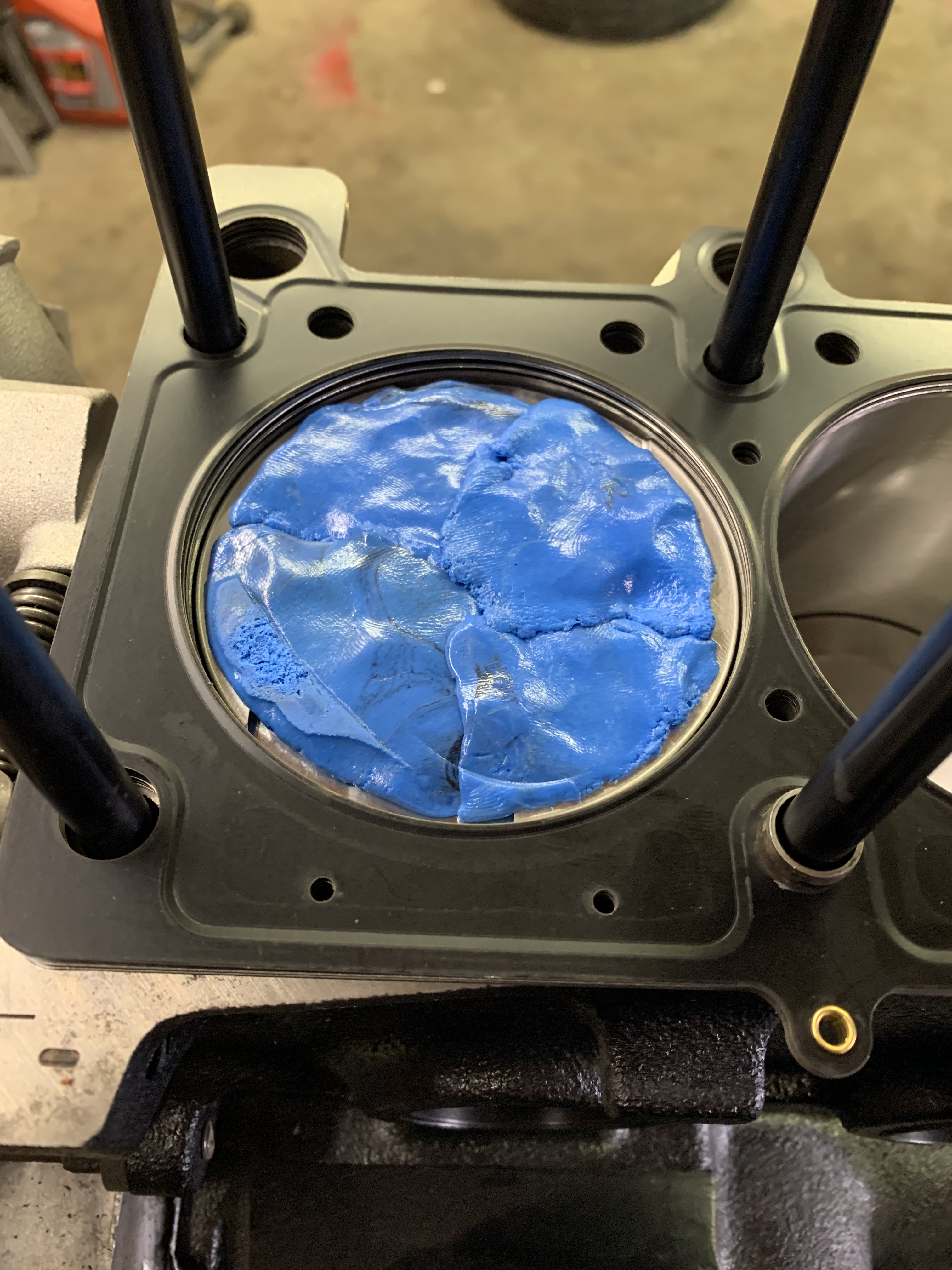

Set the head on the block with no HG and timed it with some old components I had lying around and carefully turned it to feel for any interference, valve lash all the way out, just to do a prelim check.

I then put on my cometic 86mm .070 HG, snugged the head down, adjusted lash to .010 and tested with some clay. Clearance looks good, I am happy.

Torqued the head down with ARPs, and started assembling some small stuff.

Despite the piles of M20 stuff I have lying around, I still had to order oil filter housing seals and a revised intermediate shaft pulley. When I get the new pulley in, I'll time it back up with the Gates Racing belt I have for the engine.

I have a cheap IE oil pan baffle but don't really want to drill into my pan, so I'm considering just getting a VAC or AAF oil pan baffle and having my buddy weld it in. It'll push back my timeline, but if it's worth it, I'll definitely wait on it. Opinions welcome on that subject.

Untitled by Bobbie Morrone, on Flickr

Untitled by Bobbie Morrone, on Flickr

Untitled by Bobbie Morrone, on Flickr

Untitled by Bobbie Morrone, on Flickr

Untitled by Bobbie Morrone, on Flickr

Untitled by Bobbie Morrone, on Flickr

Untitled by Bobbie Morrone, on Flickr

Untitled by Bobbie Morrone, on Flickr

Untitled by Bobbie Morrone, on Flickr

Untitled by Bobbie Morrone, on Flickr

Untitled by Bobbie Morrone, on Flickr

Untitled by Bobbie Morrone, on Flickr

Comment

-

OoOOoooOo prettttyyyyyyy

Looking good brother!'86 325e Zinnoberrot /// '02 325ci Schwarz II /// '18 M4 Azurite Black Metallic ///

Albie325 Build Thread | Albie325 COTM Jan 2021

Comment

Comment