Originally posted by reelizmpro

View Post

Announcement

Collapse

No announcement yet.

Integra Type R sells for $34k

Collapse

X

-

Many structural improvements to the body, lighter glass, 5 lug hubs vs 4, bigger brakes, lower and stiffer suspension, the engine is still a B18.....but shares basically nothing but the block with the GS-R.Need parts now? Need them cheap? steve@blunttech.com

Chief Sales Officer, Midwest Division—Blunt Tech Industries

www.gutenparts.com

One stop shopping for NEW, USED and EURO PARTS!

-

You are wrong they have reinforced suspension mount points and seam welded chassis. the motors while in the same family were vastly different. The only thing on the head that the gsr and type r share is the exhaust valve springs. They were also 5 lug vs 4 lug and then there are all the other bit you stated in your first post. Its not too surprising that these are going up. It was a collectors car from the get go since the production figures for the us market cars were 320 units in 1997 and 1,000 units in 1998. 1,350 units were built for the US in 2000 and 1,158 in 2001. A total of 3,823 Integra Type R were produced for the us marketOriginally posted by reelizmpro View PostI think they had strut braces and just bolt on stuff. Don't know if there were more reinforcement other than that. Most if not all were 5 lug (i think the first ones were 4 lug IIRC) with bigger accord wagon calipers, etc. They are closer to the GSR than the M3 is to the 325i with the M3 having a different body and engine.:shock:Originally posted by blunttechLevent guzzles vanilla hazelnut creamer like its my semen

Comment

-

Okay cool, some M3's had extra reinforcements on the front subframes but it's hardly worth mentioning. Same thing can be done to any E30 for minimal cost. The B18C5 being vastly different doesn't change the fact that it's still a B18 and people have been building their own LS/VTEC's forever. Again, not a big deal in the Honda game where so many parts are interchangeable. My point was, they are closer to the GSR than the M3 is to the 325i with the M3 having a different body and engine that's all. That isn't saying that the GSR and Type R are the same.Last edited by reelizmpro; 04-30-2016, 01:54 PM."I'd probably take the E30 M3 in this case just because I love that little car, and how tanky that inline 6 is." - thecj

85 323i M TECH 1 S52 - ALPINEWEISS/SCHWARZE

88 M3 - LACHSSILBER/SCHWARZE

89 M3 - ALPINEWEISS II/M TECH CLOTH-ALCANTARA

91 M TECHNIC CABRIO TURBO - MACAOBLAU/M TECH CLOTH-LEATHER

Comment

-

If the Honda chassis is seam welded, I think you'd have an easier time converting an 'iS' BMW to M3 spec than a regular Integra to Type R spec. Aside from the body panels, M3 mods are bolt on, and other than the engine the stuff is all pretty easy to come by, if not a little pricey. Honda stuff is all mix and match, but so is E30 stuff.

I'd seam weld my car if I had the means. It probably needs it, with the solid plastic bushings and stiff suspension.

IG @turbovarg

'91 318is, M20 turbo

[CoTM: 4-18]

'94 525iT slicktop, M50B30 + S362SX-E, 600WHP DD or bust - updated 3-17

Comment

-

M3 5-lug pieces, C-pillar covers, and that spark plug (lol) wrench are a more than a lil pricey. And, I think it may be easier to seam weld an iS than it is to graft M3 panels and glass?Originally posted by varg View PostIf the Honda chassis is seam welded, I think you'd have an easier time converting an 'iS' BMW to M3 spec than a regular Integra to Type R spec. Aside from the body panels, M3 mods are bolt on, and other than the engine the stuff is all pretty easy to come by, if not a little pricey. Honda stuff is all mix and match, but so is E30 stuff.I Timothy 2:1-2

Comment

-

I'm talking about performance, not cosmetics. You don't need the wide fenders and cosmetic pieces to match the performance of an M3.Originally posted by markseven View PostM3 5-lug pieces, C-pillar covers, and that spark plug (lol) wrench are a more than a lil pricey. And, I think it may be easier to seam weld an iS than it is to graft M3 panels and glass?

IG @turbovarg

'91 318is, M20 turbo

[CoTM: 4-18]

'94 525iT slicktop, M50B30 + S362SX-E, 600WHP DD or bust - updated 3-17

Comment

-

Based on everything I've heard about seam welding a chassis, it's a pretty time consuming ordeal, and a royal pain in the ass since you have to completely strip the chassis, including all the seam sealer, which rarely if ever comes out easily. No, I'd say it's likely easier to graft on the various M3 panels.Originally posted by markseven View PostM3 5-lug pieces, C-pillar covers, and that spark plug (lol) wrench are a more than a lil pricey. And, I think it may be easier to seam weld an iS than it is to graft M3 panels and glass?

Comment

-

Varg, real M3 stuff is hard to come by which is why prices are high. Mechanicals bolt on sure but quarters, c pillar cap and windshields would have to be bonded. That isn't cheap either. That stuff is unique and not used on any other e30."I'd probably take the E30 M3 in this case just because I love that little car, and how tanky that inline 6 is." - thecj

85 323i M TECH 1 S52 - ALPINEWEISS/SCHWARZE

88 M3 - LACHSSILBER/SCHWARZE

89 M3 - ALPINEWEISS II/M TECH CLOTH-ALCANTARA

91 M TECHNIC CABRIO TURBO - MACAOBLAU/M TECH CLOTH-LEATHER

Comment

-

If you would kindly read above, you'd see that I am speaking of performance, not cosmetics.Originally posted by reelizmpro View Postc pillar cap and windshields would have to be bonded. That isn't cheap either. That stuff is unique and not used on any other e30.

IG @turbovarg

'91 318is, M20 turbo

[CoTM: 4-18]

'94 525iT slicktop, M50B30 + S362SX-E, 600WHP DD or bust - updated 3-17

Comment

-

So am I. Afterall, people brought up seam welding. Bonded windshields make the chassis stiffer. The M3 body has a lower drag coefficient and wide fenders accommodate bigger wheels. The M3 was purpose built. Everything was done for performance, not cosmetics."I'd probably take the E30 M3 in this case just because I love that little car, and how tanky that inline 6 is." - thecj

85 323i M TECH 1 S52 - ALPINEWEISS/SCHWARZE

88 M3 - LACHSSILBER/SCHWARZE

89 M3 - ALPINEWEISS II/M TECH CLOTH-ALCANTARA

91 M TECHNIC CABRIO TURBO - MACAOBLAU/M TECH CLOTH-LEATHER

Comment

-

Originally posted by varg View PostI'm talking about performance, not cosmetics. You don't need the wide fenders and cosmetic pieces to match the performance of an M3.^This. The cap raised and elongated the rear of the car to improve aerodynamics (lower drag, increased downforce). The box flares allowed bigger wheels which allowed for 5-lug hubs and bigger brakes.Originally posted by reelizmpro View PostSo am I. Afterall, people brought up seam welding. Bonded windshields make the chassis stiffer. The M3 body has a lower drag coefficient and wide fenders accommodate bigger wheels. The M3 was purpose built. Everything was done for performance, not cosmetics.

BMW did a lot of design and engineering to homologate and make the E30 competitive - their diligence and the result of their labor proved to be world class. Would the E30 M3 have dominated in the manner that it did with less? The world will never know. The spark plug tool mention was a joke, btw :D

So, according to Wikipedia, the US Type R had extra spot welds (among other things), and the JDM version had 5-lug hubs. No mention of seam welding?

Over the years I've read the numerous threads on BF.C on rotisseries and seam welding. Definitely not for the faint of heart and time consuming, but IMO, grafting an M3 rear half onto a regular E30 takes true paint / body skills (and probably a frame jig) to do it right?Originally posted by rturbo 930 View PostBased on everything I've heard about seam welding a chassis, it's a pretty time consuming ordeal, and a royal pain in the ass since you have to completely strip the chassis, including all the seam sealer, which rarely if ever comes out easily. No, I'd say it's likely easier to graft on the various M3 panels.I Timothy 2:1-2

Comment

-

A frame jig? What? As far as I know (someone feel free to correct me), it's mostly the quarter panels, and the C pillar/rear window piece. I know the trunk is different too, but that's bolted on. That's body work, not frame work. You would have to know what you're doing, but it's not like you have to swap literally the entire rear end of the car.Originally posted by markseven View PostOver the years I've read the numerous threads on BF.C on rotisseries and seam welding. Definitely not for the faint of heart and time consuming, but IMO, grafting an M3 rear half onto a regular E30 takes true paint / body skills (and probably a frame jig) to do it right?

Comment

-

I couldn't find a definitive answer about the ITR being seam welded either, only people who said it was. Then again I also found where people simply said it had additional reinforcements (which can include seam welding). I found a few owners had their ITR seam welded which lead me to believe that it wasn't already.

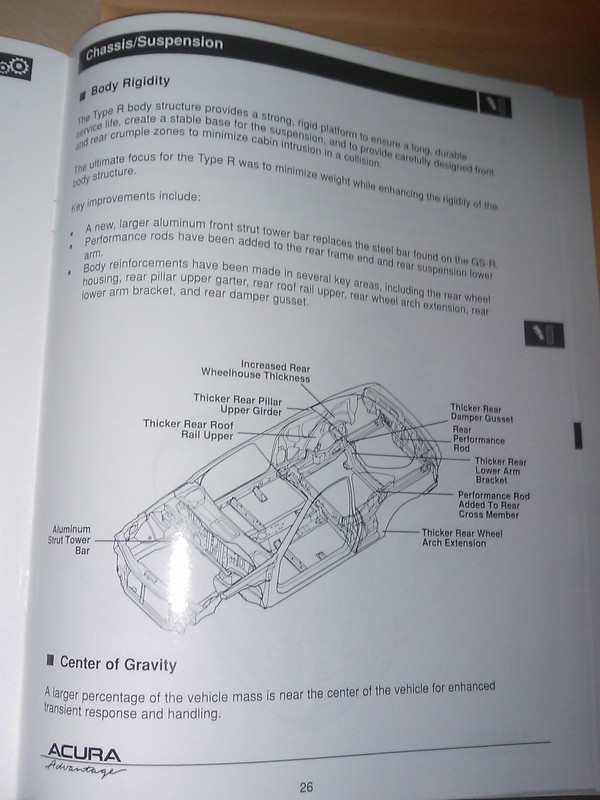

"There is no special welding

Difference in physical frame is the following

-Rear wheel housing

-rear pillar upper garter

-rear roof rail upper

-rear wheel arch extension

-rear lower arm bracket

-rear damper gusset

type R loses (for weight reduction)

-sunroof (duh)

-vanity mirrors

-cruise control

-rear wiper (97 anyway)

-dashboard insulator

-transmission mount

-driveshaft and shifter dynamic damper

-melt-sheet for the floor stamping"

From what I gather, it only had additional stitch welding in some spots and those spots could be those areas mentioned above. The entire chassis was not seam welded.

As for the M3 conversion, to do it right with OEM sheetmetal requires a ton of work and welding. A frame machine isn't required as it's not the entire rear half of the car, it's just the quarter panels and C pillar cap area. The trunk is bolted on but you'd need the M3 specific arms, trunk gasket, torsion springs, rear glass, interior rear deck extension, 3rd brake light, trunk panels, gas filler extension, etc. All of which are either NLA and/or crazy expensive. Many people do it if they have access to a donor car.Last edited by reelizmpro; 05-05-2016, 01:22 PM."I'd probably take the E30 M3 in this case just because I love that little car, and how tanky that inline 6 is." - thecj

85 323i M TECH 1 S52 - ALPINEWEISS/SCHWARZE

88 M3 - LACHSSILBER/SCHWARZE

89 M3 - ALPINEWEISS II/M TECH CLOTH-ALCANTARA

91 M TECHNIC CABRIO TURBO - MACAOBLAU/M TECH CLOTH-LEATHER

Comment

-

Very interesting stuff. Nice to see an OEM layout what's different about the structure. I don't think anyone was saying that turning a regular e30 into an M3 is easy, but there's also no reason to write off a Type R Integra as just a GS-R with bolt-ons. It may not have a seam-welded chassis (don't know where I heard that, as that would be pretty crazy for a factory car), but those changes still seem pretty significant. Sure, it doesn't have bespoke body parts like an m3, but it still seems pretty special to me... I mean - I'm not gonna buy one at this price, but it also doesn't seem that crazy to me.

Who knows - maybe if it had cool flares, we wouldn't even be having this discussion...diamantschwarz 1991 318is

Comment

-

Maybe if the ITR had absolutely killed it on road courses, in rallies, endurance, on a world stage, we wouldn't even be having this discussion...Originally posted by word is bond View PostVery interesting stuff. Nice to see an OEM layout what's different about the structure. I don't think anyone was saying that turning a regular e30 into an M3 is easy, but there's also no reason to write off a Type R Integra as just a GS-R with bolt-ons. It may not have a seam-welded chassis (don't know where I heard that, as that would be pretty crazy for a factory car), but those changes still seem pretty significant. Sure, it doesn't have bespoke body parts like an m3, but it still seems pretty special to me... I mean - I'm not gonna buy one at this price, but it also doesn't seem that crazy to me.

Who knows - maybe if it had cool flares, we wouldn't even be having this discussion...I Timothy 2:1-2

Comment

Comment