So today as I was almost home, the car started idling very poorly, bogged and died at a stop sign. It took a lot of cranking to get it to restart, and once it did, it would bog and stumble at <500RPM, and then stall. Once it is in this mode, opening the throttle makes no difference at all, other than increasing the amount of backfiring (not a lot, but I get a few good puffs).

If I give it throttle while cranking, it will start right up and run smoothly on all 4 cylinders above 1200RPM, with minimal backfiring. It was running nice and strong immediately prior to all of this, and I was out beating on it in the hills for fun. Now, if I can get it to rev above the idle speed, it will have a hesitation around 1500RPM, which was not there before.

For the last couple of months, I have been noticing that the car will bog a bit at idle for about a minute after a cold start, usually not quite enough to stall, and giving it a blip of throttle usually sorted it out. I assumed it was a dirty ICV, but cleaning it made no difference.

Stuff I do not think it is:

- Since the car runs smoothly from 1500-3000RPM (I have not had a chance to try to rev it higher, I was just happy to limp it home), I am assuming it is NOT fuel delivery related. The injectors, pump and filter all have under 30000 miles on them.

- AFM. There is no AFM because I am running a MAF conversion. If the converter was bad, it would not run well at any RPM.

- TPS. I checked the voltage output in accessory mode and it varies smoothly from 0.5V to 4V throughout its range.

- Cam position sensor. Even though the stomp test gives me code 1244, unplugging the cam sensor makes no difference. This code seems to come up for a variety of reasons other than a bad cam sensor (which is what it is supposed to indicate).

- Cracked head. No milky oil, and the expansion tank is not overflowing.

- Idle control valve. If it was this, opening the throttle would have an immediate effect. Again, if the car is in death-bog mode, nothing I do with the throttle makes a difference.

- Ignition coil. It is unlikely that more than one died simultaneously, and I know what an M42 feels like running on 3 cylinders. This ain't it lol.

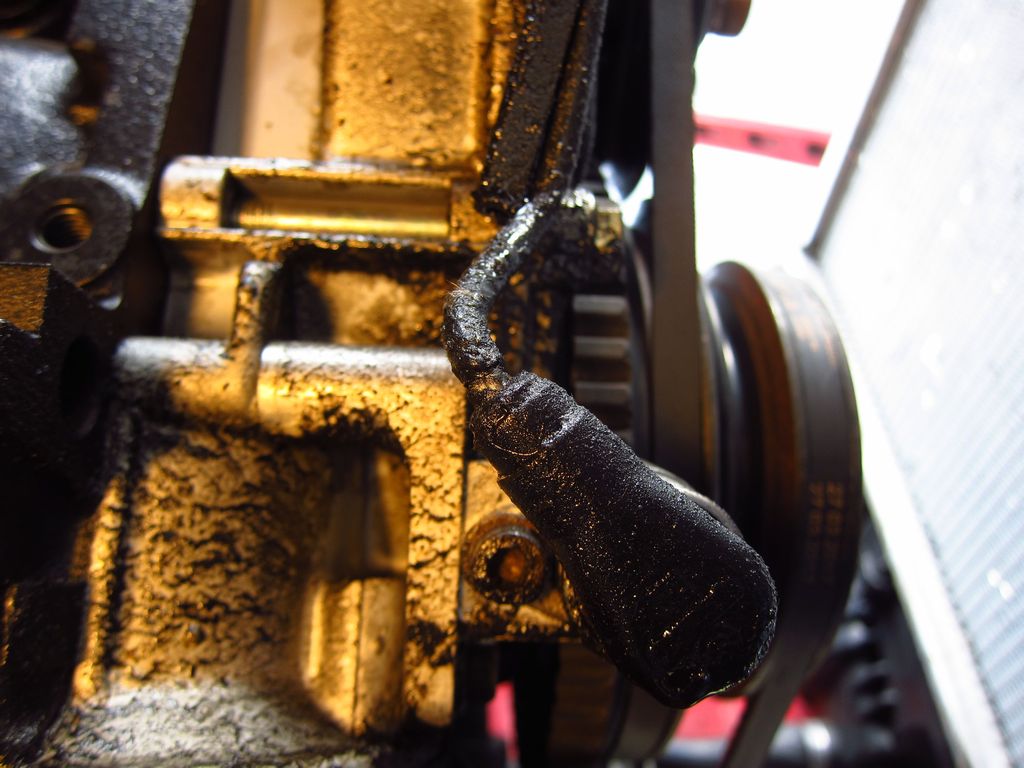

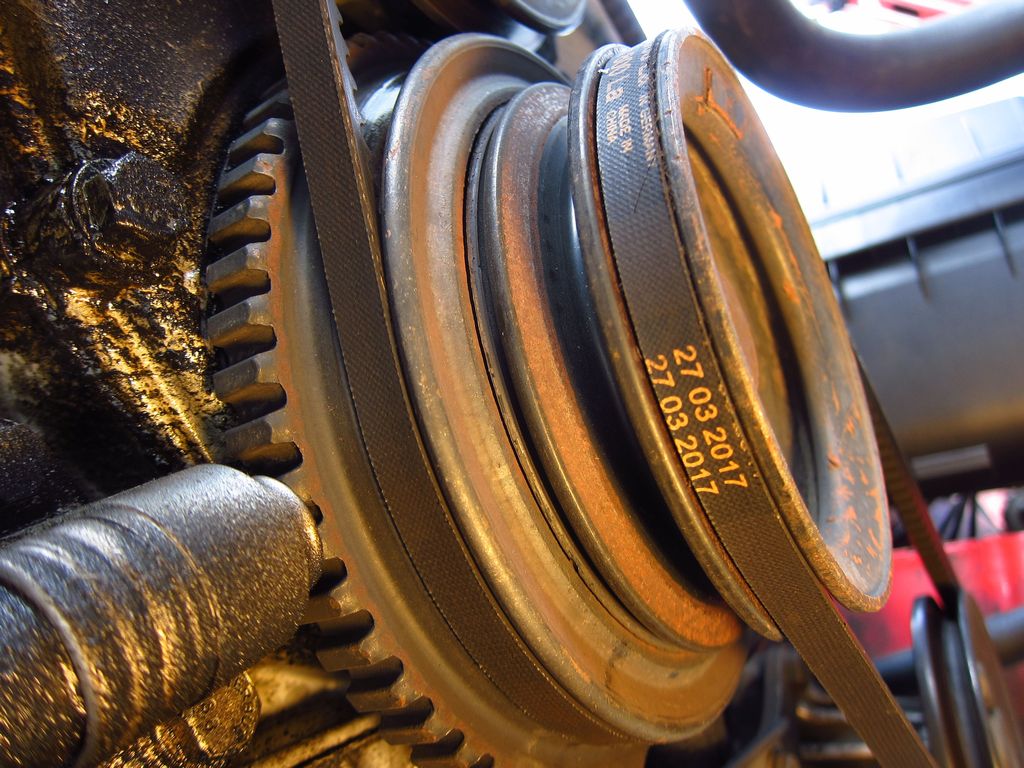

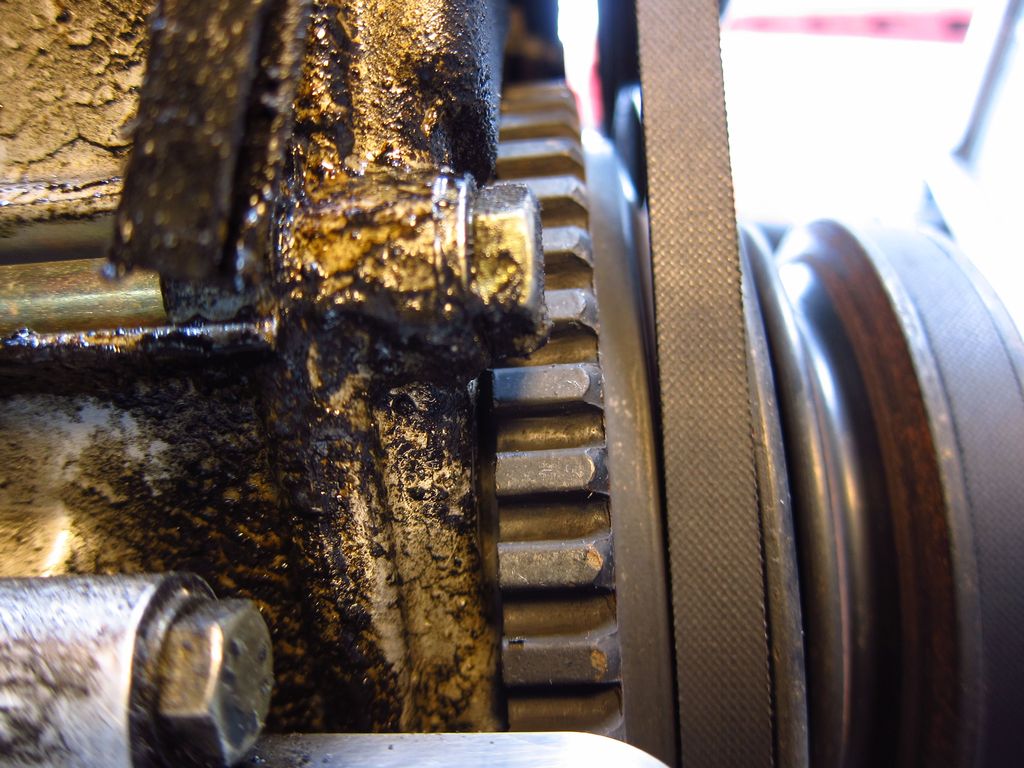

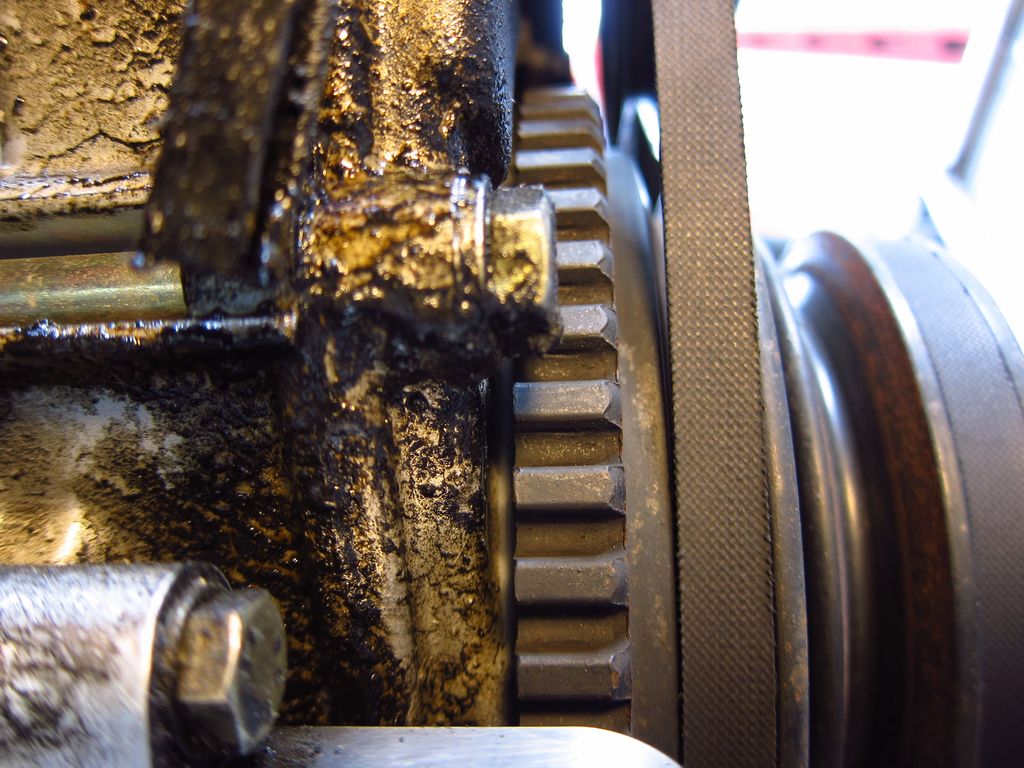

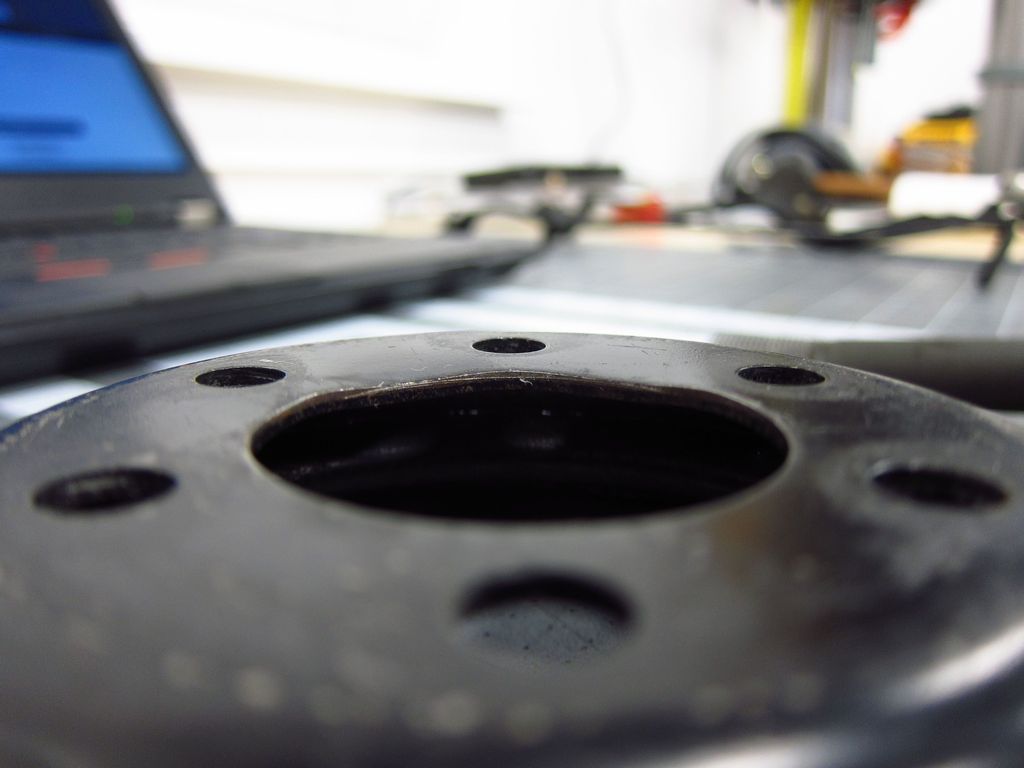

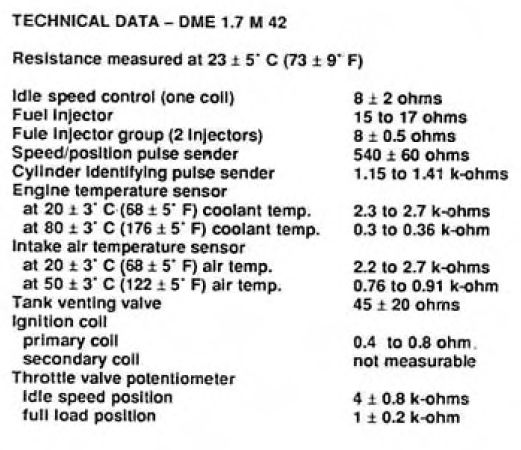

My main suspicion is the crank position sensor. It is one of the few original sensors left on the engine, and I cannot think of anything else that would make the idle so bad while also causing throttle inputs to have zero effect. I measured its resistance out to be 590 Ohms, which is at the high end of the spec. God help me, the OEM ones are $232 lol (which is fine, I don't mind buying one if it the real cause!).

Any thoughts? Am I missing anything?

If I give it throttle while cranking, it will start right up and run smoothly on all 4 cylinders above 1200RPM, with minimal backfiring. It was running nice and strong immediately prior to all of this, and I was out beating on it in the hills for fun. Now, if I can get it to rev above the idle speed, it will have a hesitation around 1500RPM, which was not there before.

For the last couple of months, I have been noticing that the car will bog a bit at idle for about a minute after a cold start, usually not quite enough to stall, and giving it a blip of throttle usually sorted it out. I assumed it was a dirty ICV, but cleaning it made no difference.

Stuff I do not think it is:

- Since the car runs smoothly from 1500-3000RPM (I have not had a chance to try to rev it higher, I was just happy to limp it home), I am assuming it is NOT fuel delivery related. The injectors, pump and filter all have under 30000 miles on them.

- AFM. There is no AFM because I am running a MAF conversion. If the converter was bad, it would not run well at any RPM.

- TPS. I checked the voltage output in accessory mode and it varies smoothly from 0.5V to 4V throughout its range.

- Cam position sensor. Even though the stomp test gives me code 1244, unplugging the cam sensor makes no difference. This code seems to come up for a variety of reasons other than a bad cam sensor (which is what it is supposed to indicate).

- Cracked head. No milky oil, and the expansion tank is not overflowing.

- Idle control valve. If it was this, opening the throttle would have an immediate effect. Again, if the car is in death-bog mode, nothing I do with the throttle makes a difference.

- Ignition coil. It is unlikely that more than one died simultaneously, and I know what an M42 feels like running on 3 cylinders. This ain't it lol.

My main suspicion is the crank position sensor. It is one of the few original sensors left on the engine, and I cannot think of anything else that would make the idle so bad while also causing throttle inputs to have zero effect. I measured its resistance out to be 590 Ohms, which is at the high end of the spec. God help me, the OEM ones are $232 lol (which is fine, I don't mind buying one if it the real cause!).

Any thoughts? Am I missing anything?

Comment