10-11-2018

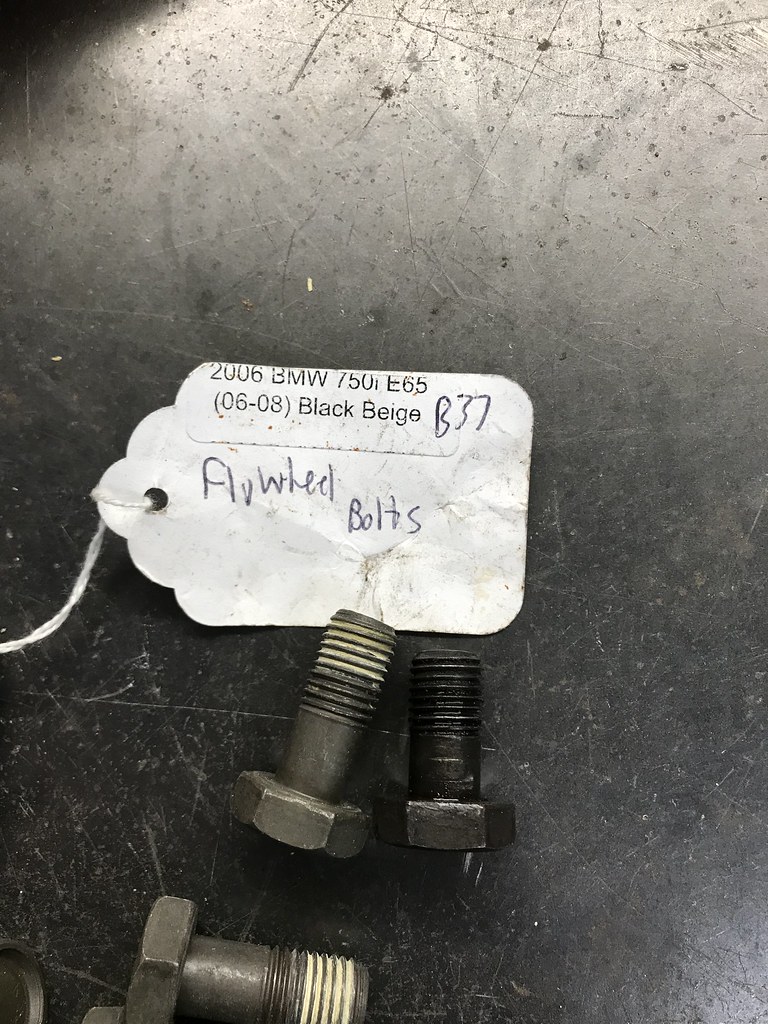

Not much done last night other than some garage cleanup, organizing, and checking to see if I can swap ring gears between flywheels. The answer is yes and no. The inner diameter of the m10 is just enough that I would need to machine or grind a millimeter or more from the m42 ring to get it to fit. Probably just going to stick with either the m10 starter or spring for the reman one.

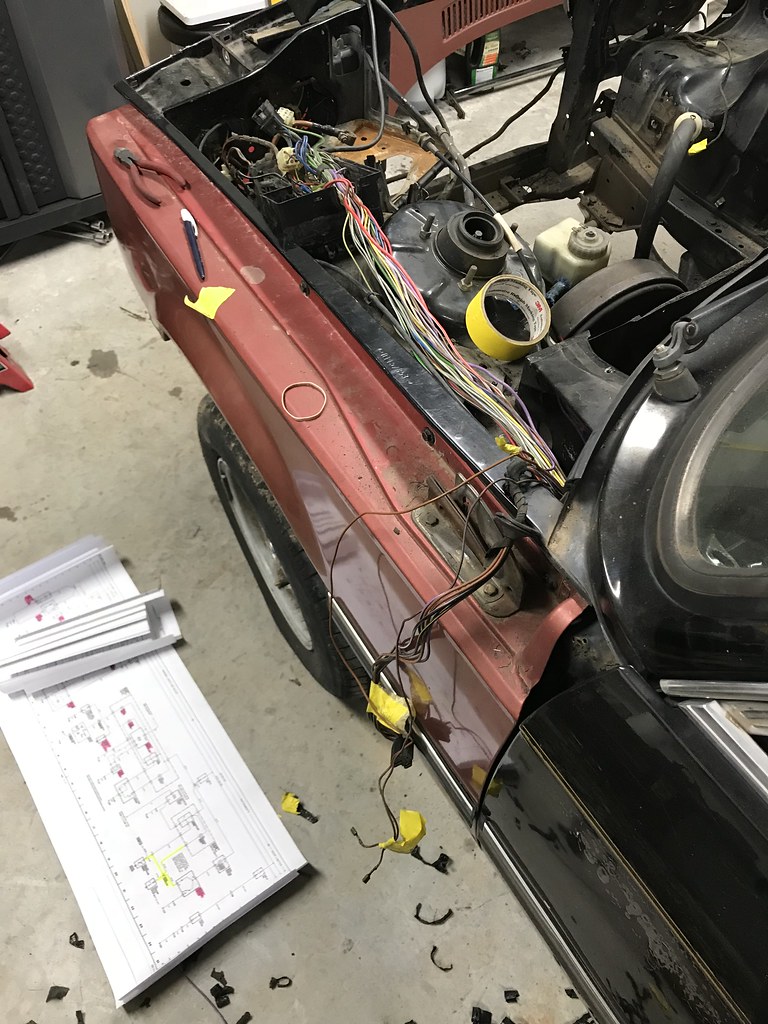

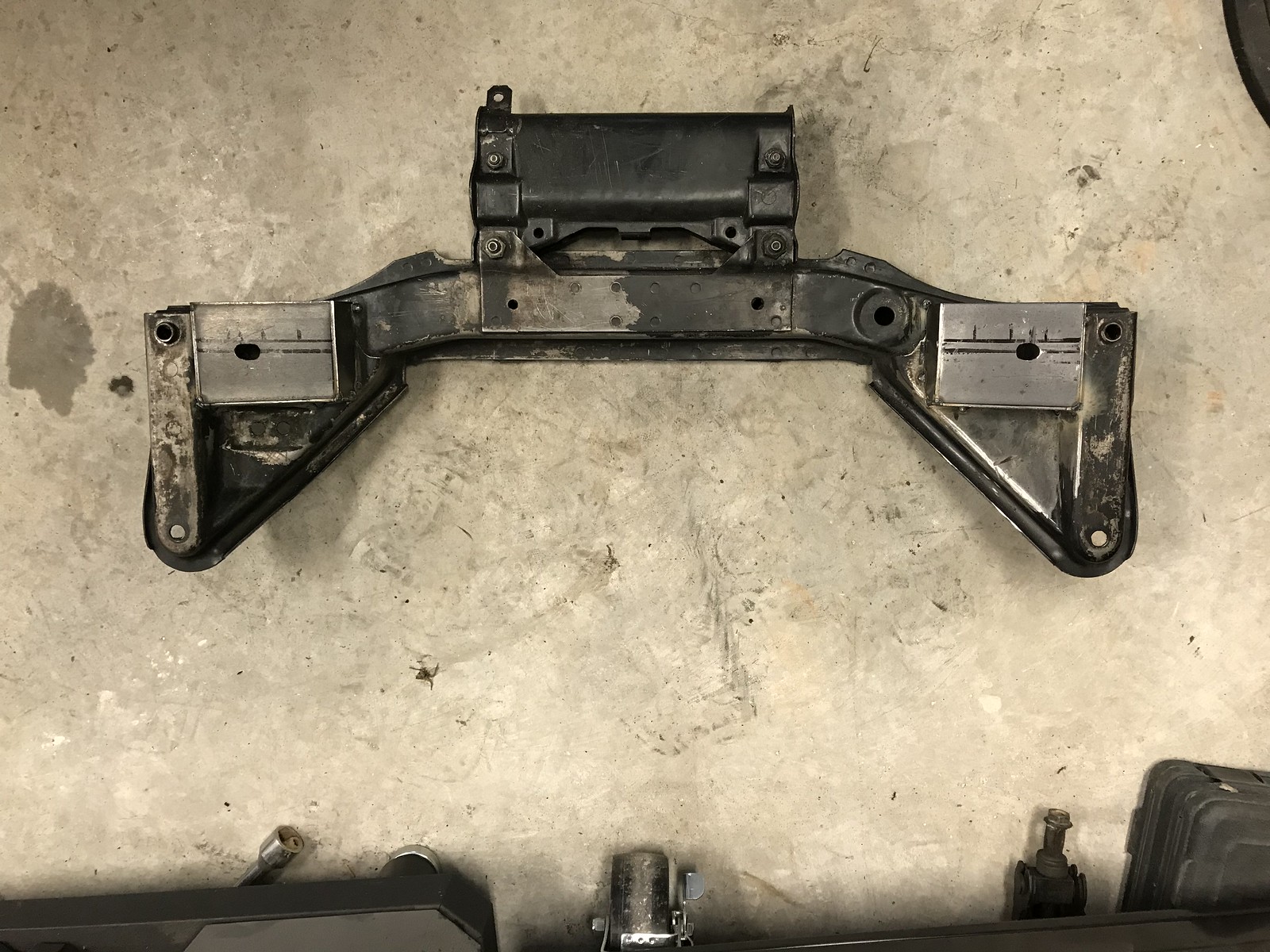

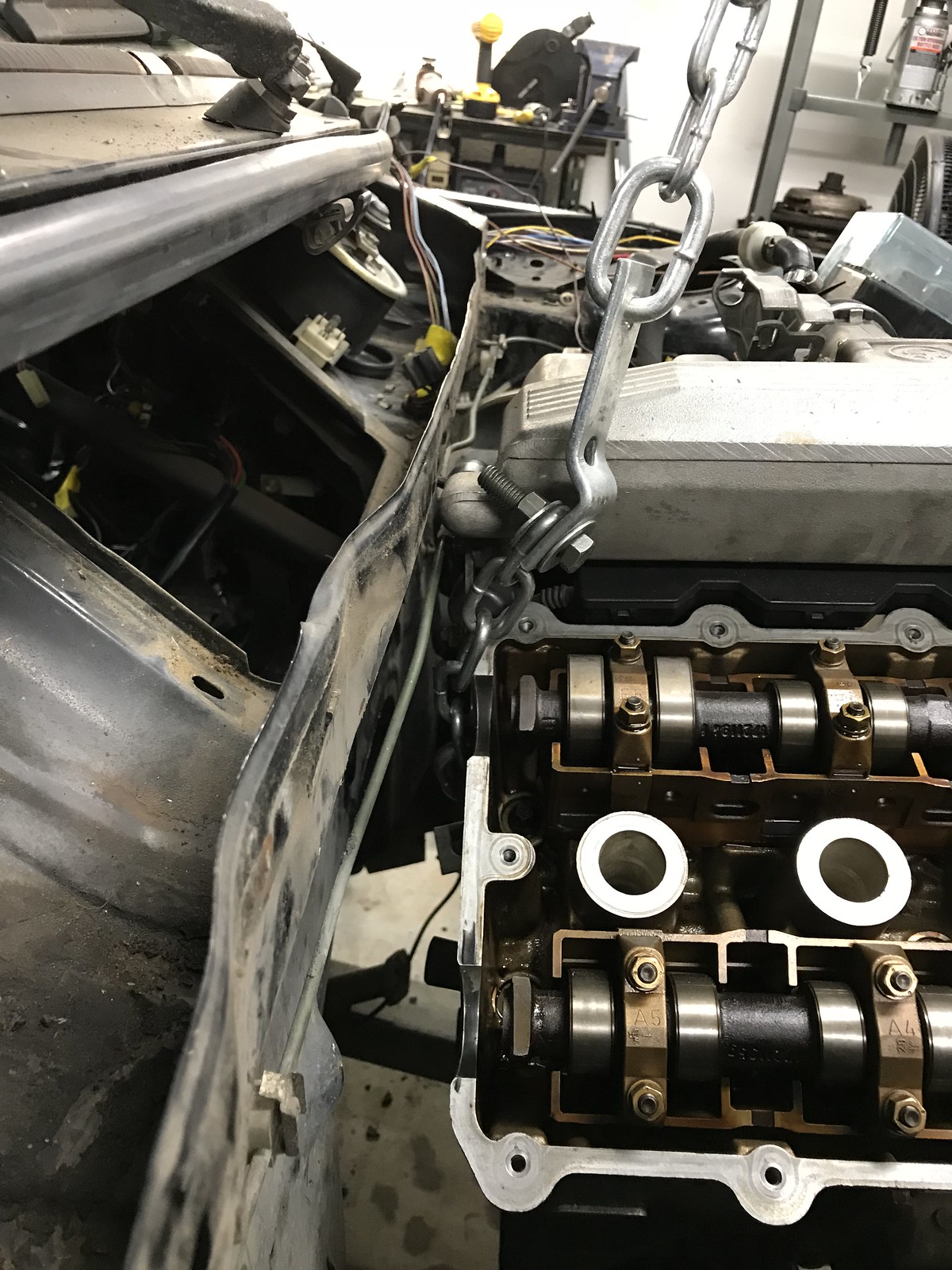

One thing that sucks about BMW trailing arm suspension is the lack of adjustability. You can buy kits with brackets and eccentric bolts, but they are not budget friendly. Like around $200 for most because the BMW bolts used are around $17-20 EACH before even buying the washers and nuts. So I've found a cheaper solution intended for VW/Audis that still gets me the adjustment I want and effectively cost half of what most places are charging. The eccentrics are just slightly under the size of the ebay brackets, but when turned they rotate and adjust properly without issue. I will be putting a couple spot welds on each one once I get a good alignment figured out.

E30 subframe adjuster brackets : $53.75 (Ebay)

Eccentric bolt # WHT001679 : $27.44 for 4 (FCP Euro)

Eccentric washer # WHT001675 : $8.08 for 4 (FCP Euro)

Nut # N90635001 : $2.76 for 4 (FCP Euro)

Total : $92.02

Untitled by hatchethairy, on Flickr

Untitled by hatchethairy, on Flickr

Untitled by hatchethairy, on Flickr

Untitled by hatchethairy, on Flickr

Untitled by hatchethairy, on Flickr

Untitled by hatchethairy, on Flickr

Not much done last night other than some garage cleanup, organizing, and checking to see if I can swap ring gears between flywheels. The answer is yes and no. The inner diameter of the m10 is just enough that I would need to machine or grind a millimeter or more from the m42 ring to get it to fit. Probably just going to stick with either the m10 starter or spring for the reman one.

One thing that sucks about BMW trailing arm suspension is the lack of adjustability. You can buy kits with brackets and eccentric bolts, but they are not budget friendly. Like around $200 for most because the BMW bolts used are around $17-20 EACH before even buying the washers and nuts. So I've found a cheaper solution intended for VW/Audis that still gets me the adjustment I want and effectively cost half of what most places are charging. The eccentrics are just slightly under the size of the ebay brackets, but when turned they rotate and adjust properly without issue. I will be putting a couple spot welds on each one once I get a good alignment figured out.

E30 subframe adjuster brackets : $53.75 (Ebay)

Eccentric bolt # WHT001679 : $27.44 for 4 (FCP Euro)

Eccentric washer # WHT001675 : $8.08 for 4 (FCP Euro)

Nut # N90635001 : $2.76 for 4 (FCP Euro)

Total : $92.02

Untitled by hatchethairy, on Flickr

Untitled by hatchethairy, on Flickr Untitled by hatchethairy, on Flickr

Untitled by hatchethairy, on Flickr Untitled by hatchethairy, on Flickr

Untitled by hatchethairy, on Flickr

Comment