I'm stoked part of my old car is living out the rest of its life in something this crazy lol.

Those fenders turned out so great. Super good call with the e46 graft

Those fenders turned out so great. Super good call with the e46 graft

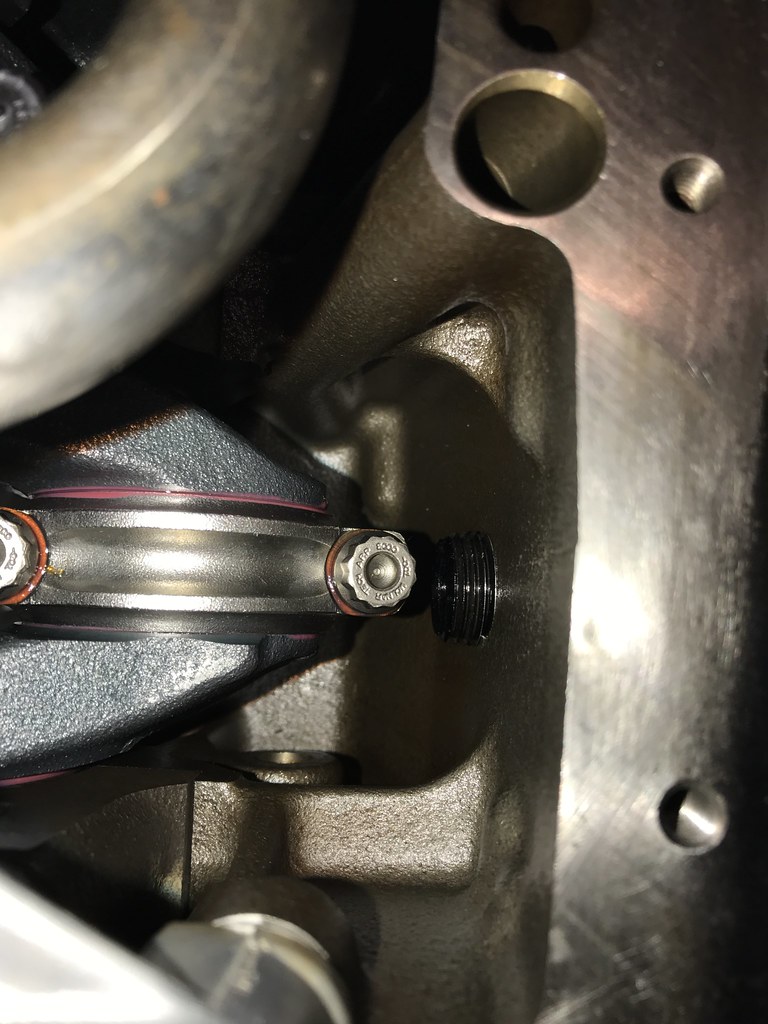

E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr E30 Build by Jason H, on Flickr

E30 Build by Jason H, on Flickr

Comment