Test fit the the Megan headers I ordered off Ebay, lined up just fine on the head. Not to shabby for $300.

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

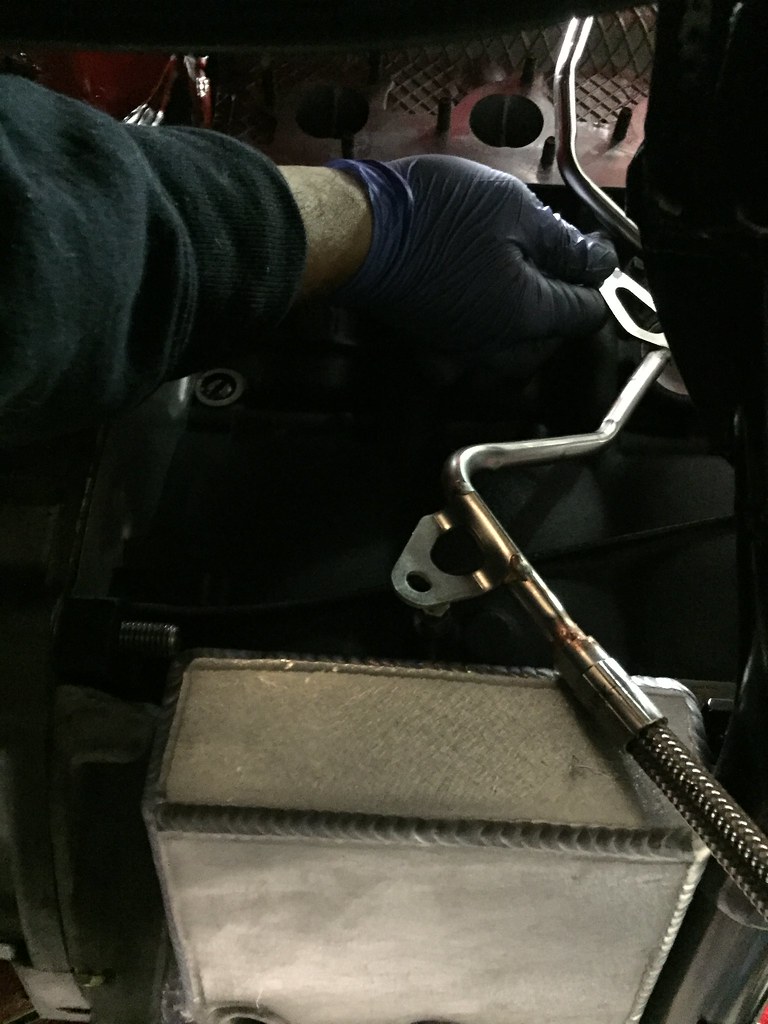

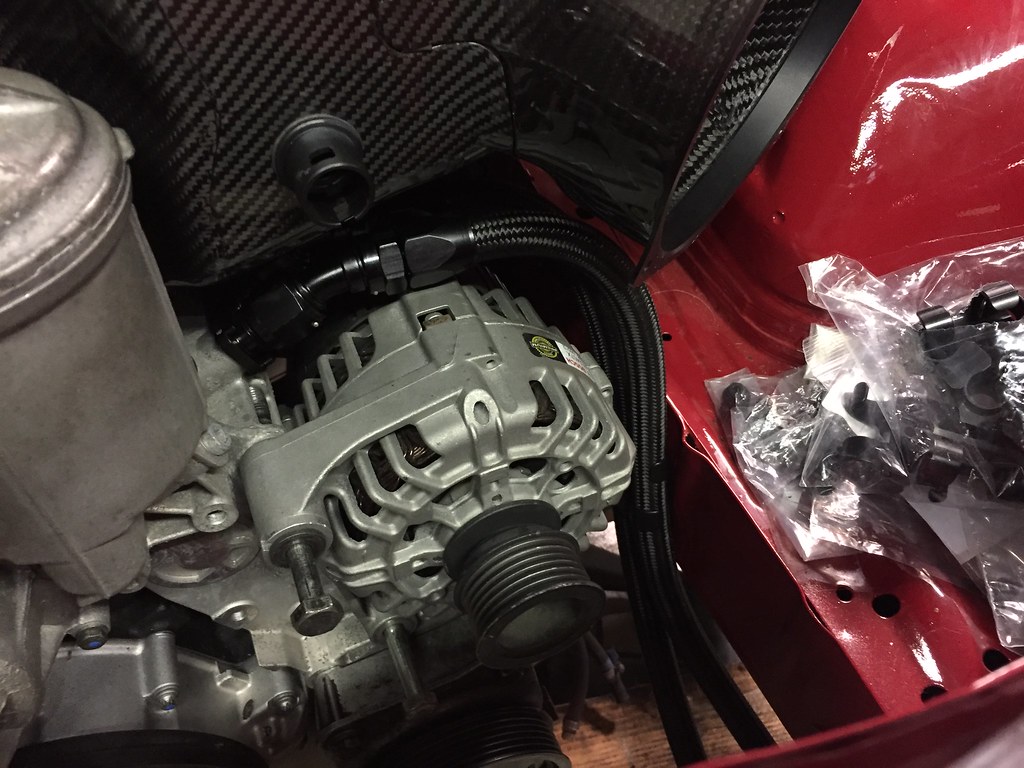

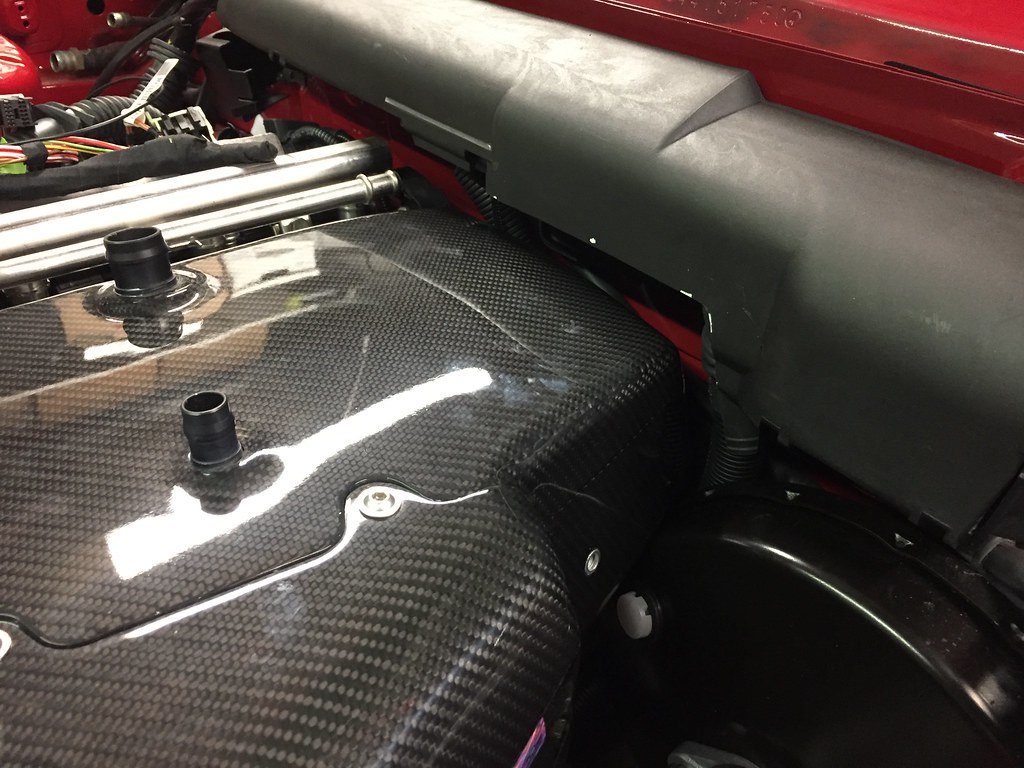

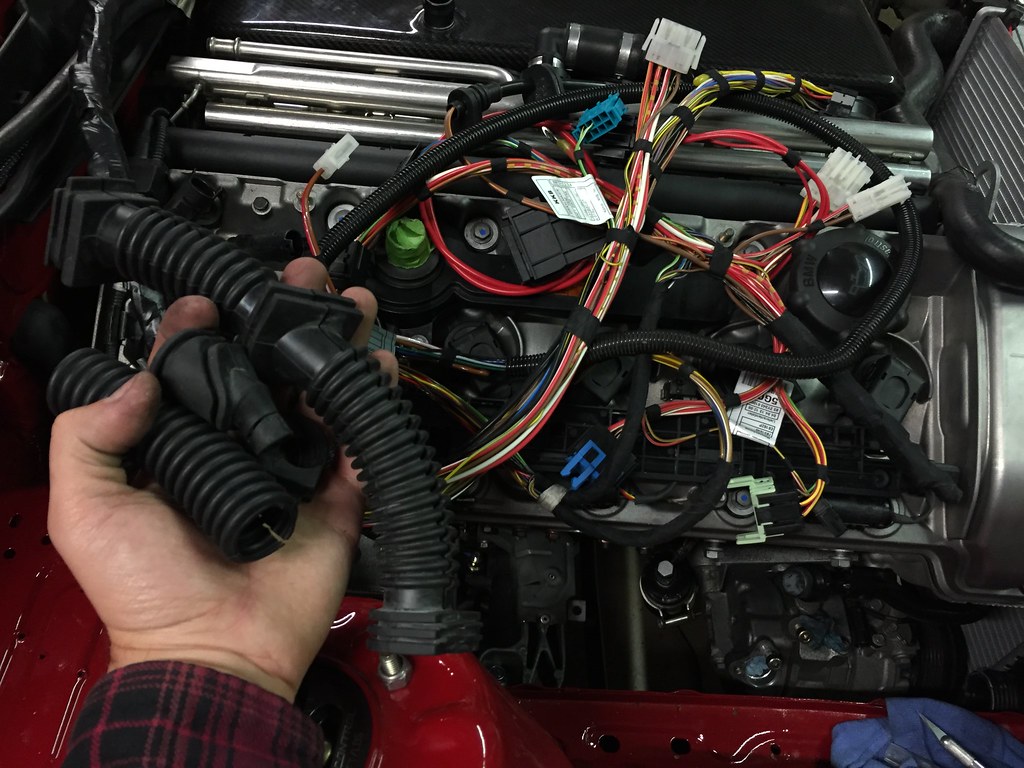

Last Sunday I had everything buttoned up on the motor. A friend came by to help me guide it in. Felt like Id never see the day!

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr

And shes in! That's where I stand as of now. Onto wiring and pluming where I know I am going to have lots of questions, and already do.

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on FlickrLast Sunday I had everything buttoned up on the motor. A friend came by to help me guide it in. Felt like Id never see the day!

Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on Flickr Untitled by Evan Nessim, on Flickr

Untitled by Evan Nessim, on FlickrAnd shes in! That's where I stand as of now. Onto wiring and pluming where I know I am going to have lots of questions, and already do.

Comment