Garagistic E30 adjustable Rear Subframe exchange program

Collapse

X

-

You're probably right. I learned from my dad who is overly cautious about stuff like that. I see muffler shops do it all the time I guess so it can't be that unsafe.

I have been fabricating on cars for years, and never had an issue with welding near the fuel tank. Only 1 of the ~15 or so cars I put a roll cage in had the tank removed, and that was only because it was getting a fuel cell.

I have no issue tightening the nut down using an "S" shaped starter wrench.

Maybe a TIG tack would be a safer bet but still I don't really see the ned to tack those bolts anyway.

I'll have to try the starter wrench method. I ended up modifying a box wrench and it still wasn't enough for me to make adjustments. Had to pull my gas tank for a fuel system revamp so adjusted the passenger toe when it was out. Very easy without the fuel tank in the way.Leave a comment:

-

Garagistic makes their eccentric washers out of aluminum, can't tack to steel bolts.

No offense, but I’m not sure this is a great idea for a couple of reasons. First is the next time an alignment is needed it’s pretty much impossible without grinding off the tacks and second welding that close to the gas tank is not advisable. Also refer to gas tank comment when considering grinding off tack welds for later adjustment. Getting a wrench in to make adjustments is difficult enough (pretty much impossible for passenger toe with gas tank installed), let alone a grinder to remove welds down the road.

If you plan to always run the same tires, tire pressures, and ride height, and if you also plan for your suspension to never get old and settle, then maybe this makes sense...but only after tack welding with the gas tank removed.

I have been fabricating on cars for years, and never had an issue with welding near the fuel tank. Only 1 of the ~15 or so cars I put a roll cage in had the tank removed, and that was only because it was getting a fuel cell.

I have no issue tightening the nut down using an "S" shaped starter wrench.Leave a comment:

-

No offense, but I’m not sure this is a great idea for a couple of reasons. First is the next time an alignment is needed it’s pretty much impossible without grinding off the tacks and second welding that close to the gas tank is not advisable. Also refer to gas tank comment when considering grinding off tack welds for later adjustment. Getting a wrench in to make adjustments is difficult enough (pretty much impossible for passenger toe with gas tank installed), let alone a grinder to remove welds down the road.

If you plan to always run the same tires, tire pressures, and ride height, and if you also plan for your suspension to never get old and settle, then maybe this makes sense...but only after tack welding with the gas tank removed.Leave a comment:

-

Awesome, glad it worked out, and glad Garagistic stood behind their product.Picked the car back up this morning, and can report success.

The guys at the shop were actually surprised that it came down to a faulty trailing arm as the issue. Swapped out the problematic drivers side, and were able to adjust it into alignment with the right side.

I'll try and post #'s later on.

Thanks again to Garagistic for making this right, now to get all my $$$ back from core refunds and the other trailing arm that I paid for to correct the issue.

I've yet to do any extensive driving, but so far I'm happy at the end of this long journey.Leave a comment:

-

Leave a comment:

-

Glad to hear it all worked out for you. Might help someone down the line diagnose a similar issue. Good stuff!Picked the car back up this morning, and can report success.

The guys at the shop were actually surprised that it came down to a faulty trailing arm as the issue. Swapped out the problematic drivers side, and were able to adjust it into alignment with the right side.

I'll try and post #'s later on.

Thanks again to Garagistic for making this right, now to get all my $$$ back from core refunds and the other trailing arm that I paid for to correct the issue.

I've yet to do any extensive driving, but so far I'm happy at the end of this long journey.Leave a comment:

-

Picked the car back up this morning, and can report success.

The guys at the shop were actually surprised that it came down to a faulty trailing arm as the issue. Swapped out the problematic drivers side, and were able to adjust it into alignment with the right side.

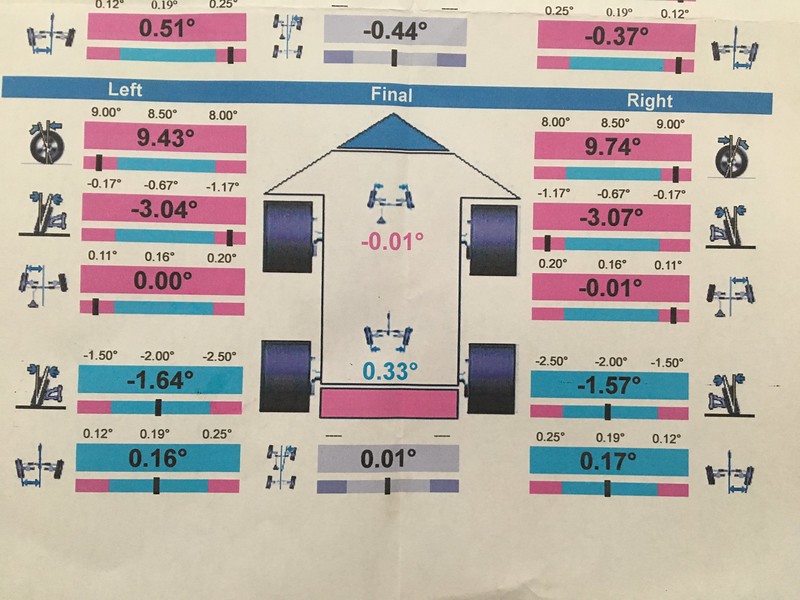

I'll try and post #'s later on.

Thanks again to Garagistic for making this right, now to get all my $$$ back from core refunds and the other trailing arm that I paid for to correct the issue.

I've yet to do any extensive driving, but so far I'm happy at the end of this long journey.Leave a comment:

-

Last edited by LateFan; 06-22-2018, 11:00 AM.Leave a comment:

-

Did you get this resolved? I'm in DFW and have rear subframe and trailing arms in my Garagistic cart, but mine are both rusty so I figured I wouldn't be able to get the core charge back. Before I commit $1200+ to this I'd want to be sure everything works out for you.Many thanks for the responses guys, I’m quite bummed and really was excited with the quality product initially.

For trouble shooting purposes, I’m curious why the trailing arms are your first guess? How can i know for sure? I will update everyone on status this afternoon but after working all day on the install we were wiped out and disapointed it didnt come together as planned. Uber fees suck too when i was expecting to drive the car home!

My front subframe was protected from rust by the oil leak, yes!Leave a comment:

-

The "proper" way to install a rear camber/toe kit is to put your car on an alignment rack before you install them to see how much you need for adjustment in each direction. However, Garagistic just installs these "in der Mitte" as a once size fits all approach.I need some schooling on these please....

1. If you go with the weld-on adjustable mounts, how is the placement of these done so they're accurate? I can see me dropping it off at Cowboy Bob Welders and they're not too sharp on millimeters much less 10ths of millimeters.

2. What keeps the eccentric bolts from slipping in the slots? Isn't there another fabricator out there where I read about constant slipping out of adjustment?

3. Do you have a jig to check trailing arms for previous bends? From what I know, it's very hard to tell if they're bent from looking at them.

I'm very interested in the outcome of mr denton's problem and whether it's a quality control issue.

We rebuilt the subframe and trailing arms with all new OEM bushings, mildly lowered it with H&R sport springs, and we trashed a new set of rear tires in less than 8000 miles. So we need a solution.

With that said, they should provide enough adjustment to solve the majority of rear camber/toe issues outside of extreme cases like stanceboylowlow and/or bent TAs, etc, and I'm assuming if you are an 'extreme' case you could provide them with this information beforehand to get them welded on properly.

In regards to eccentric bolts slipping, it's common for them to move unfortunately. However, IE came out with a Posi-Lock Style kit to help mitigate the slippage. These are not the adjusters Garagistic is using.

With all of that said, I am on GC coilovers and am running the Garagistic rear adjustable subframe with Poly bushings, and am not slammed, but am fairly low. The Garagistic subframe offered enough adjustment for me to get the rear of my car in spec.

Hope this helps.

Untitled by Bobbie Morrone, on Flickr

Untitled by Bobbie Morrone, on Flickr

Untitled by Bobbie Morrone, on Flickr

Untitled by Bobbie Morrone, on Flickr

Leave a comment:

-

I need some schooling on these please....

1. If you go with the weld-on adjustable mounts, how is the placement of these done so they're accurate? I can see me dropping it off at Cowboy Bob Welders and they're not too sharp on millimeters much less 10ths of millimeters.

2. What keeps the eccentric bolts from slipping in the slots? Isn't there another fabricator out there where I read about constant slipping out of adjustment?

3. Do you have a jig to check trailing arms for previous bends? From what I know, it's very hard to tell if they're bent from looking at them.

I'm very interested in the outcome of mr denton's problem and whether it's a quality control issue.

We rebuilt the subframe and trailing arms with all new OEM bushings, mildly lowered it with H&R sport springs, and we trashed a new set of rear tires in less than 8000 miles. So we need a solution.

Leave a comment:

-

Latest update is that we experienced further delays getting the replacement control arm due to a blemish on powder coating.

I'm pleased that Garagistic cares enough about sending out a quality product that they refused the powder coating and sent it back to their partner... but obviously frustrated that this has turned into a multi-week saga story with my car laid up at the shop.

ETA for the shipment is now Monday 6/25 to land at the shop, at which point we'll try reinstall and alignment. If we still have issues, then will have to assume that the subframe is the issue and I will ugly cry in my closet at the prospect of further delays.

More to come..Leave a comment:

Leave a comment: