So this weekend I was finally able to start my motor for the first time. My car has been down since April 2014, and damn is it a good feeling to turn the key.

I pulled the fuel pump relay and cranked it over for about 10 seconds to let the motor build some oil up. Plugged the relay back in, cranked it for about 5 seconds, no start. Cranked it once again, and it started right up. This being my first motor rebuild and swap, I was super excited that it started up first try without any "no spark or no fuel" issues. Haven't drove it yet because as of right now its open headers.

I have two reasons that I am bumping my old ass thread. First being excited. Second to give advice to the "first swap" guys since a lot of threads can be misleading.

Here are some general tips from what I have gained:

First, and most importantly, research as much as you can. READ the 24v section. I browse the swap subforum more than any other, just to acquire any little information I can, regardless if I'm having that problem, or just sitting on the toilet trying to kill some work hours.

Secondly, I believe that over-thinking leads to most problems that you may think you have. Being very nervous as it was my first swap, I was scared to do a lot of things. The crazy thing about it is, this swap is actually pretty damn simple. Yes, there are a little bit of custom things needed, or you might purchase a few wrong parts, or you might get some shitty quality stuff from some vendors, BUT.. its all apart of the fun.

And here are also a few things that people seem to keep hidden or I was unclear of (I will add to this as I remember):

- If you are using a E36 Harness, use a E36 02 sensor. If you are using an E34 Harness, use an E34 02 sensor. The lengths are completely different. The E34 sensor is about 4' long, I think?

- My evap canister was interfering with my intake boot. Flip the bracket around and it opens up a lot of space as it moves it closer to the firewall.

- I had a lot of confusion with the E30 CSB and 328i/M3 driveshaft and people saying the E30 CSB goes on backwards. The CSB still needs to point the same direction as it originally does, It just gets installed on the opposite "half" of the driveshaft therefore, you are pressing it on in a "reverse" order.

- The REVSHIFT SWAP MOUNTS ARE NOT COMPATIBLE WITH AN iX BOOSTER. They designed it around the Porsche booster, so I had to sell off my iX setup and get the Porsche 944 booster, which used the stock E30 M/C. Although, I still had to space my motor up on the drivers side with three washers for it to clear. Yes my intake is shaved.

- If you don't plan on using AC, make sure you either still leave the AC pulley on the crank pulley attached, or you must get slightly shorter bolts. The stock bolts with no AC pulley will interfere with the timing cover/front main seal.

- I read a lot about the powersteering setup for the swaps, and a lot of people say they use stock M20 hoses or E36 Hoses, but the only one I found that worked fine from either of those was the E36 High Pressure Line and the feed line from either (either DIY or buying a new one). As for the return, I could not figure out how to make the stock E30 Hard Line section work. I was thinking of cutting and welding it to get the angle I wanted, but came across this https://www.belmetric.com/bnjf16910-...=1041_855_1135 . I used the smaller barb of the two, so I could run a cooler.

- For the engine to radiator coolant hoses, I used some from Napa. P/N: 8484. They are just right angle hoses that you trim to fit. Worked perfect. (Credit goes to User: 36brua)

Thanks for reading!

M20 finally pooped out

Collapse

X

-

Picked up S52 Pistons and Crank for $300. now dropping off the bare M50 block to the machine shop.

Does anybody know if the oil spray nozzle is only on the S50 motor? real oem doesn't show it on the S52 and I can't find any information on it. Maybe they found it to be not needed?

If anybody has a picture of the front of the block with the timing cover off, but most of the stuff intact, please post it.

Thank you..Leave a comment:

-

S50 Crank was fucked.

I found a good S52 crank for cheap. My plan is to bore the M50 block out to 86.4mm, sourcing some s52 pistons, and using the s50 rods since they are the same.

Does this sound funny to anybody? is there any reason why this wouldnt work?Leave a comment:

-

Picked up a M50 to strip for the block, and was planning on throwing the S50 Rotating assembly in, but now I'm looking at piston rings and holy shit OE rings are expensive.

Are the Grant rings successful?Leave a comment:

-

The block went to the machine shop yesterday and by visual inspection, the machinist said that it doesn't look salvageable. He will be checking into it more and giving me a final word in the next few days.

In the mean time, I've been researching if you can punch out a 2.5l Vanos M50 Block to 86mm bore safely. From what I've read, about 75% say yes, max bore is 87mm, and 25% saying something a long the lines of only certain blocks can be punched out. What I am getting at, is I want to use the stock S50 Pistons/Rods/Crank. Is this feasible? Any insight is greatly appreciated.

Thanks.Leave a comment:

-

I didnt snap any pics of the crank, but there is some good wear where it ate the thrust bearing. I'm picking up a good one up in the next couple days for a good price.

The main caps should be okay use like that?Leave a comment:

-

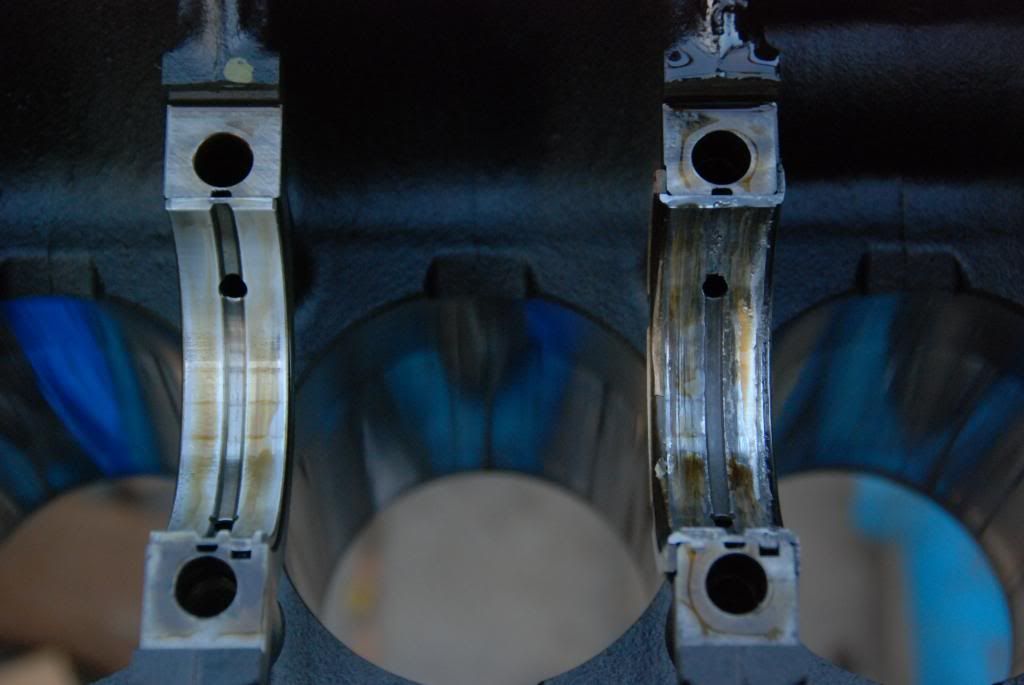

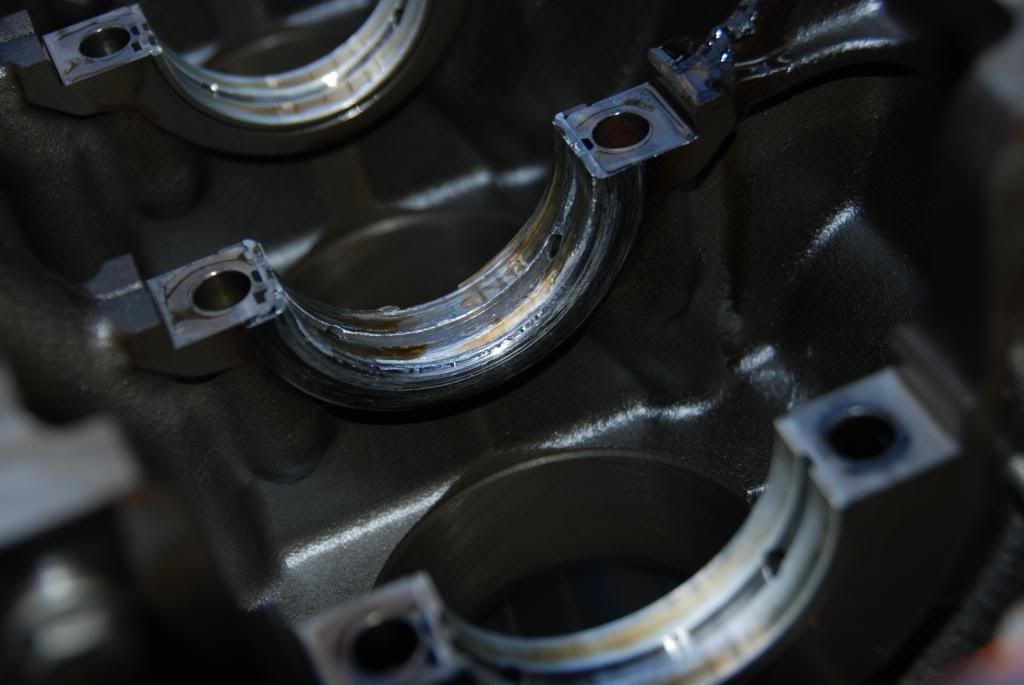

Judging by the pictures, a few of the main caps don't look too happy. The same could probably said about the crank. Have any pics of the crankshaft?Leave a comment:

-

-

Looks like your going to need a good machine shop. Terry Tinney in Livermore does great work. He did my head on my track car with a S52.

Leave a comment:

-

-

Bad news was found.

A couple of the cylinders have some scoring felt with a finger nail, and one cylinder has some pitting.

I need some advice.

I'm sure there is more, but I've found that the two piston manufactures that are mostly used are MaxSil and JE. MaxSil being OE replacements and JE being high performance with minimal price differences. Should I pull the trigger on the Oversized JE 11.5:1 Pistons?

Probably on the higher side but:

Have people had a problem with the Glyco bearings?

Thanks.Leave a comment:

-

Really?? Haven't been there in 2 years....I'll have to drive by and see....possibly this Thursday. Will let you know.Leave a comment:

-

Stirtz Machine seems to be out of business. I found their number on Yelp, but it gets redirected when called.Go talk to Carl Stirtz over at Stirtz Machine in Oakland. That's were I got my machining done when rebuilding my s52. The guys has been around for a loooong time and knows bmw's very well. Take the cam and caps and have him take a look. They may be ok with a clean-up polish. Same for the crank.Leave a comment:

-

I honestly have no idea how it got bent, the motor was already out of the car when I bought it, therefore I can only go off of what the PO says. I'm just going to go through the whole thing. Might as well. But only thing that I assume since everything was still intact when I took the motor apart aside from a loose oil pump sprocket nut; it had to be from a previous failure.f4tj0n, i suggest you replace that bent oil spray nozzle. How'd it get bent like that?

Also, at a minimum the inner oil pump gear/shaft and sprocket should be replaced considering the condition of the splines on the shaft. You should disassemble the oil pump and see if anything else is worn as well. If the housing is good you can rebuild the oil pump yourself for less than $200.

Good call on getting another dual sprocket for the crankshaft.

I actually just looked at RealOEM this morning and seen that the parts to rebuild are available. Might take that route, or just go with the Achilles unit and just replace.

and the crankshaft sprocket is toast. From what I'm guessing is that it had to be worn from a previous failure as well, and somebody cheaped out. The lower chain tensioner rail had only a tiny section of cracked plastic on the top and wear marks on the metal towards the bottom.Leave a comment:

Leave a comment: