Am trying to take the lower timing chain cover off but i need to get the crank pulley/nut off first. Dont see it in the bentley how it's done and it's not coming off with a wrench and a screw driver wedged between two bolts i put back in.

tried sending a picture to my email twice but its not working. I'll look on real oem to help you all get a better understanding of what exactly i mean...

thanks

-mike

edit:

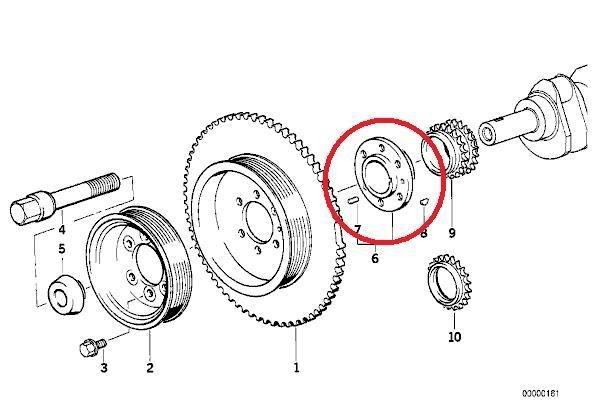

This...

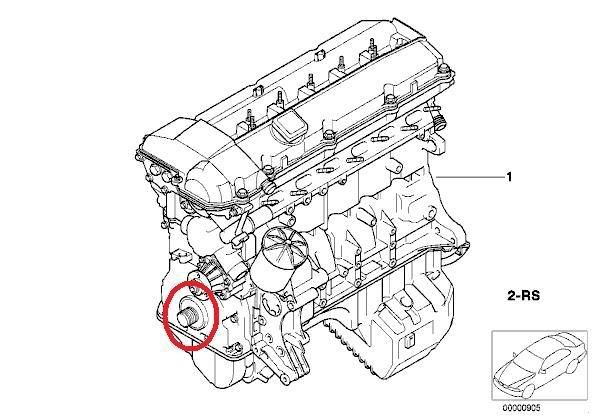

is on here...

and I can't get the lower timing case cover off...

tried sending a picture to my email twice but its not working. I'll look on real oem to help you all get a better understanding of what exactly i mean...

thanks

-mike

edit:

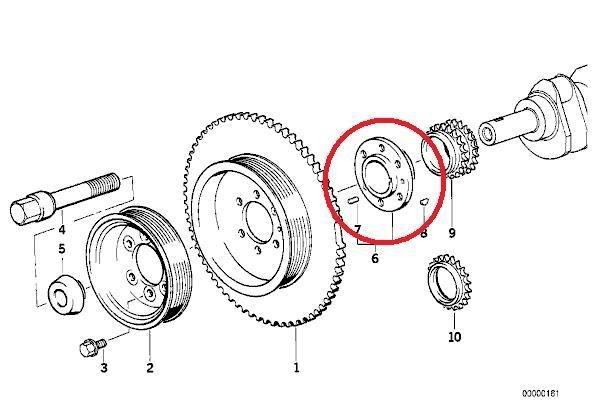

This...

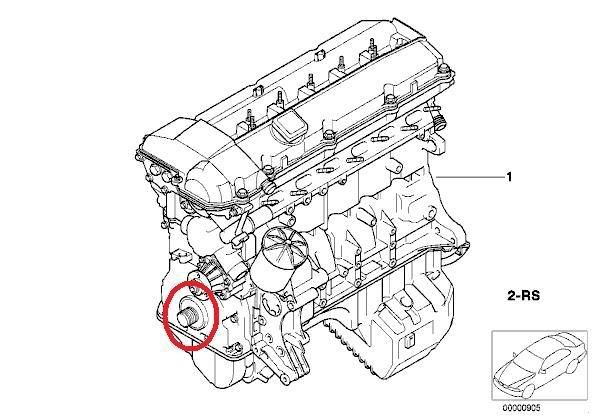

is on here...

and I can't get the lower timing case cover off...

Comment