Well, I have been slowly gathering parts for my new exhaust system over the past few months. There are a few reasons why I wanted to redo my exhaust. I knew that I wanted to get rid of the stupid 3 bolt flanges and gaskets, I wanted dual pipes, I wanted a larger muffler to aid in reducing volume and drone, and I wanted to use stainless steel. So, starting in October I began ordering parts. I was originally going to use two mufflers, one in the center section, and one at the rear. I ordered two mufflers from Jegs. One of them ended up being back ordered (as of 10/16/08), I still haven't received it and I canceled the order for it.

I ordered 4 4' lengths of 2.5" stainless steel (yes it is slightly bigger than most people would go for, but I wanted a deeper tone than I have right now which is almost ricey), 4 v-band kits for the flanges, one stainless steel O2 bung, 5 2.5" U-J mandrel bends, and the muffler that I chose is the DynoMax Ultra-Flo X muffler (part #17553). It is a straight through design with a X built in. I probably ordered more material than I potentially need, but I would rather have some left over than to have to stop half-way through a project and order parts and wait a week to get them.

I have had to borrow a SMALL argon bottle from a friend to TIG weld it all. It is a little 40 cf bottle. I have already had to have it filled twice and everything for the "cat-back" section is merely tacked in place. I will be going to the local welding supply and getting it refilled again tomorrow and hopefully I will be able to finish it up this section. I have the first V-band welded to a short length of pipe so that I can remove the 3 bolt flange from my existing "cat-back" section and be able to run the new rear section with the existing mid-section until I get that section built.

Enough with the details, here are some pictures:

Rear section:

V-Band and pipe tacked and ready to go onto the 3 bolt flange"

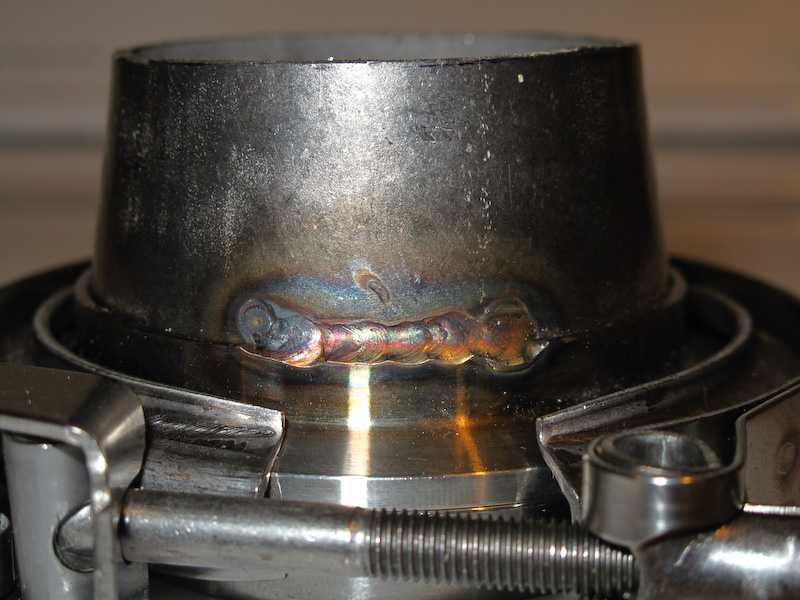

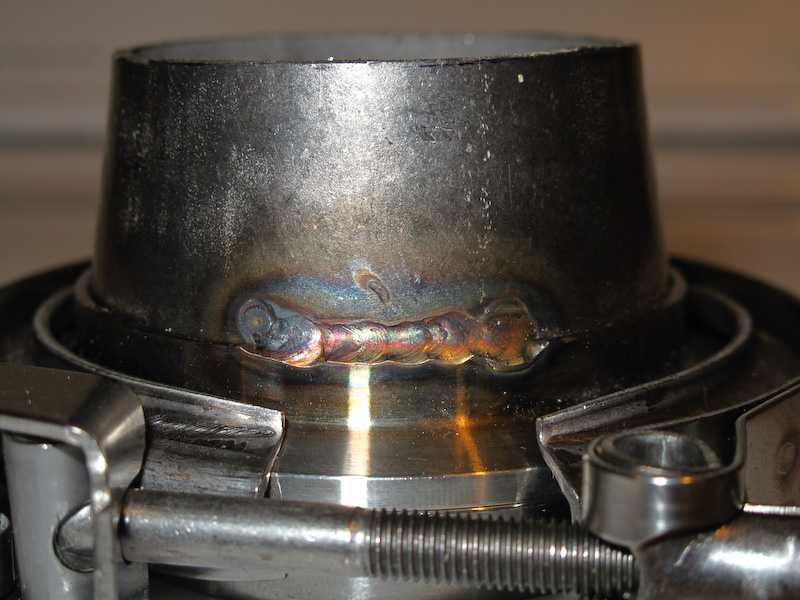

Muffler tip welds:

Muffler inlet:

Here are some videos of how my current system sounds:

Go to 1:25 on this one:

My current system is dual 2.25" with an x-pipe right underneath the shifter to an E46 M3 resonator to a random DynoMax muffler that is about 6 inches shorter (length wise) than the new one.

I ordered 4 4' lengths of 2.5" stainless steel (yes it is slightly bigger than most people would go for, but I wanted a deeper tone than I have right now which is almost ricey), 4 v-band kits for the flanges, one stainless steel O2 bung, 5 2.5" U-J mandrel bends, and the muffler that I chose is the DynoMax Ultra-Flo X muffler (part #17553). It is a straight through design with a X built in. I probably ordered more material than I potentially need, but I would rather have some left over than to have to stop half-way through a project and order parts and wait a week to get them.

I have had to borrow a SMALL argon bottle from a friend to TIG weld it all. It is a little 40 cf bottle. I have already had to have it filled twice and everything for the "cat-back" section is merely tacked in place. I will be going to the local welding supply and getting it refilled again tomorrow and hopefully I will be able to finish it up this section. I have the first V-band welded to a short length of pipe so that I can remove the 3 bolt flange from my existing "cat-back" section and be able to run the new rear section with the existing mid-section until I get that section built.

Enough with the details, here are some pictures:

Rear section:

V-Band and pipe tacked and ready to go onto the 3 bolt flange"

Muffler tip welds:

Muffler inlet:

Here are some videos of how my current system sounds:

Go to 1:25 on this one:

My current system is dual 2.25" with an x-pipe right underneath the shifter to an E46 M3 resonator to a random DynoMax muffler that is about 6 inches shorter (length wise) than the new one.

Comment