After doing a test fit of everything, I do realize that it will have to be bobbed down but not 'a significant amount'. It is really not that far off...

You definitely got taken for a ride by your machine shop. I was quoted not even half of that...

The reason I didn't believe you is because it looked like my crank had already been machined down a little. Nothing personal :)

2.8L M20 build - Now with 2.7L!

Collapse

X

-

I keep telling him he will have to machine the crank down, he doesn't believe me.

As far as you saying that cutting down the crank makes it "difficult to balance", that is 110% NOT true. Sounds to me like your machine shop was taking you for a ride with the pricing.

Here's a friend's M52 crank that was already bobbed and during balancing:

Leave a comment:

-

You will have too machine the counter weights for sure. I was planning on doing a 2.8 m20 for a while and here is some info that may help you.

A signifigant amount of counterweight must be removed from the crankshaft, this obviously makes this a difficult combo to balance.

E blocks and I blocks are not identical....there is .5mm deck height difference

The machine shop I was dealing with said expect about 800 in balancing work, they said because of the counterweight size they would need to drill and press "heavy metal" (used for balancing when there is not enough room to get the proper weight using steel) into each counterweight.

I decided after 1k machining bill, and another atleast 500 in parts it wasnt at all worth the hassle and picked up an s52. Best of luck too you man...ps I also still have all the parts I rounded up to do build this engine.Leave a comment:

-

Wow, that oil drain tube is terrible!

Looking forward to the outcome of this one. :)Leave a comment:

-

Thank you! But that is not my garage :( I'm building it at a friend's house because my garage isn't very roomy.

I have already bought the febi's and installed them. I didn't completely polish them though. I would have liked the IE HD's but at the time I was rebuilding the head the HD's were out of stock and it wasn't something I was really willing to wait for. The head i'm using is already built and installed on the engine that's in my car, don't really feel like building it again lolLeave a comment:

-

yea see what you meanI bought that cam for my 2.7i stroker because the 2.7s are notorious for dropping power after 5k rpm so I wanted to keep that power band for as long as possible. Now I am using it in the 2.8 because it would be pointless to rebuild another head to the same specs.Leave a comment:

-

Looks good so far, I like your garage.

Wrist pins should still be available new (at least they are for the M10) from the dealer or your favorite supplier (who would be going through some dealership to obtain them).

If your planning on going with new febi's instead of the IE HD's then consider polishing the rockers to reduce any potential stress risers. Especially on the weak eccentric arm undersides.

Leave a comment:

-

I appreciate the info, you don't have a part number handy do you?When I built my 2.8 back in March, I bought brand new IM shaft bearings at the dealer for $4 each. So no problem getting them at all. The catch is that the shop needed to make a tool to install them (though some people have told me a standard cam bearing install tool should have worked. The other thing is that the I.D. must be finalized after the installation of the bearings. All told, it cost me $175 for the shop to install the new bearings. But my old ones were toast, it was a must.

I bought that cam for my 2.7i stroker because the 2.7s are notorious for dropping power after 5k rpm so I wanted to keep that power band for as long as possible. Now I am using it in the 2.8 because it would be pointless to rebuild another head to the same specs.

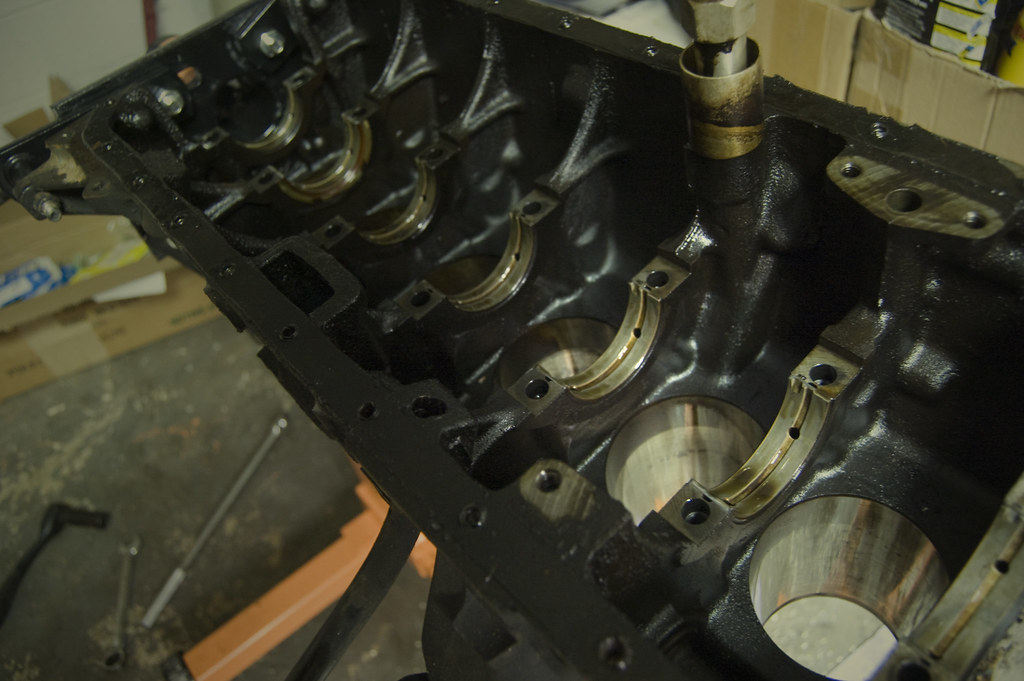

Just put in a ton of work. Broke that crank bolt free, got the crank out, rods out, everything in my trunk ready for machining :)

BMW approved crank holder :)

Front timing cover off; this engine will need some SERIOUS cleaning.

Bye bye crank

Everything all packed up

Question though: Does ANYONE know where I can buy new OEM wrist pins or will I be fine re using the eta pins? My M20B25 pistons I bought didn't come with the pins.Last edited by acolella76; 01-06-2012, 08:37 PM.Leave a comment:

-

nice sub'd to see progress and how this turns out, i see you are going to use a 272 degree cam is it not going to be dropping power at high rpms (not enough flow) or you didnt want to get custom pistons for a higher cam to workLeave a comment:

-

-

When I built my 2.8 back in March, I bought brand new IM shaft bearings at the dealer for $4 each. So no problem getting them at all. The catch is that the shop needed to make a tool to install them (though some people have told me a standard cam bearing install tool should have worked. The other thing is that the I.D. must be finalized after the installation of the bearings. All told, it cost me $175 for the shop to install the new bearings. But my old ones were toast, it was a must.The plain bearings that the intermediate shaft runs on are pressed into the block and you cant (or at least you couldn't last time i checked) buy them without buying a block. An acidic solution like a lot of shops use will destroy the bearings which obviously is a bad thing. Any non acid cleaner is fine, soap and water, brake cleaner, parts cleaner.Leave a comment:

-

They are lighter and less has to be machined off of the crank to clear the shorter skirts. Although I have heard some people that they did not need to machine anything.

Cool, thanks for the info! So something like Simple Green would be fine?The plain bearings that the intermediate shaft runs on are pressed into the block and you cant (or at least you couldn't last time i checked) buy them without buying a block. An acidic solution like a lot of shops use will destroy the bearings which obviously is a bad thing. Any non acid cleaner is fine, soap and water, brake cleaner, parts cleaner.Leave a comment:

-

The plain bearings that the intermediate shaft runs on are pressed into the block and you cant (or at least you couldn't last time i checked) buy them without buying a block. An acidic solution like a lot of shops use will destroy the bearings which obviously is a bad thing. Any non acid cleaner is fine, soap and water, brake cleaner, parts cleaner.Leave a comment:

-

What would be advantageous about short skirt pistons other than possibly being lighter weight? and are there certain years that they came in?

I am going MS via. whodwho also. I was scared of MS until I talked to him about it a bit.Leave a comment:

Leave a comment: