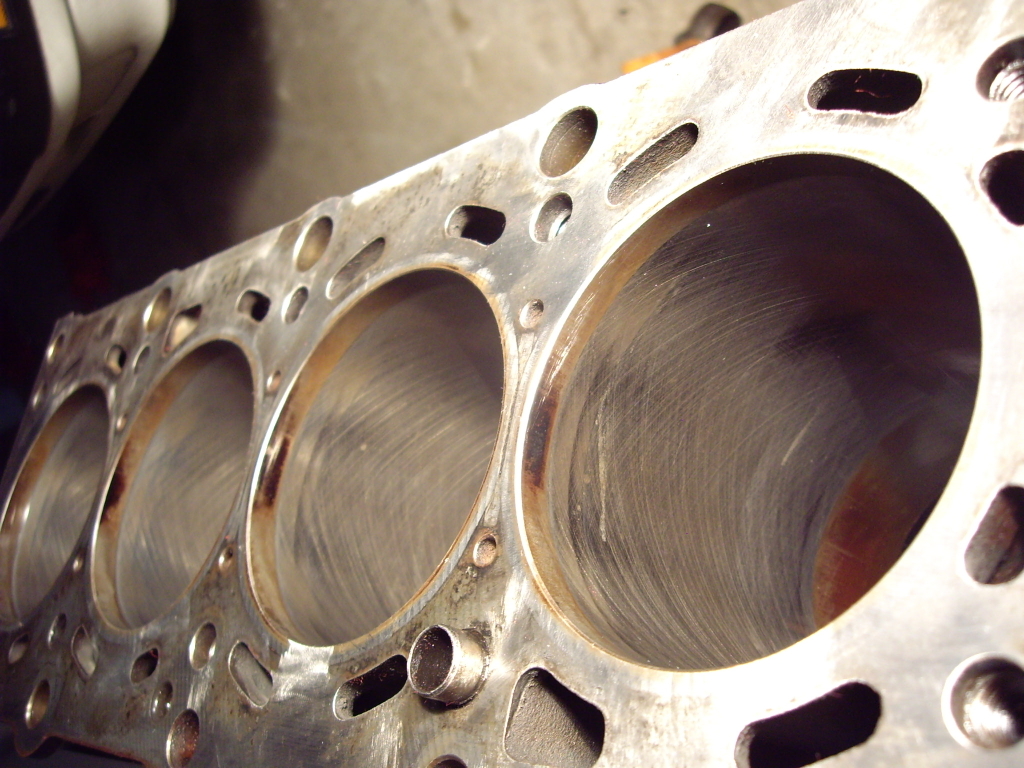

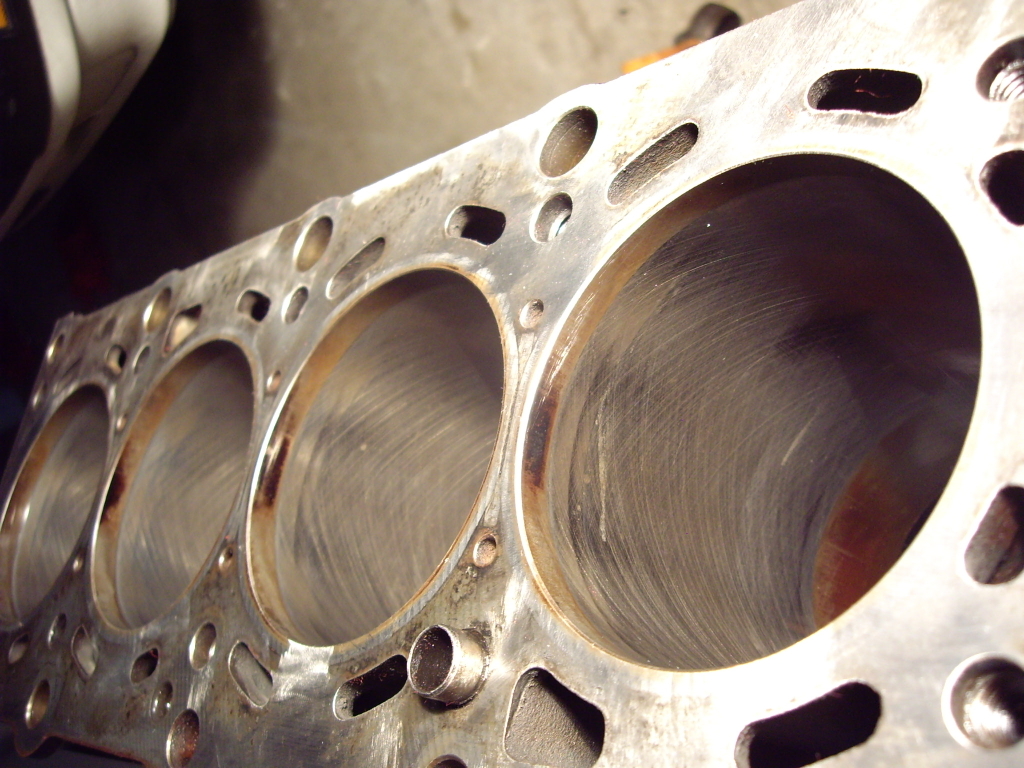

My #4 cylinder died (fouled plug, stuck open injector or a combo of the both), so I decided to just re-ring all of them and recondition the block a bit.

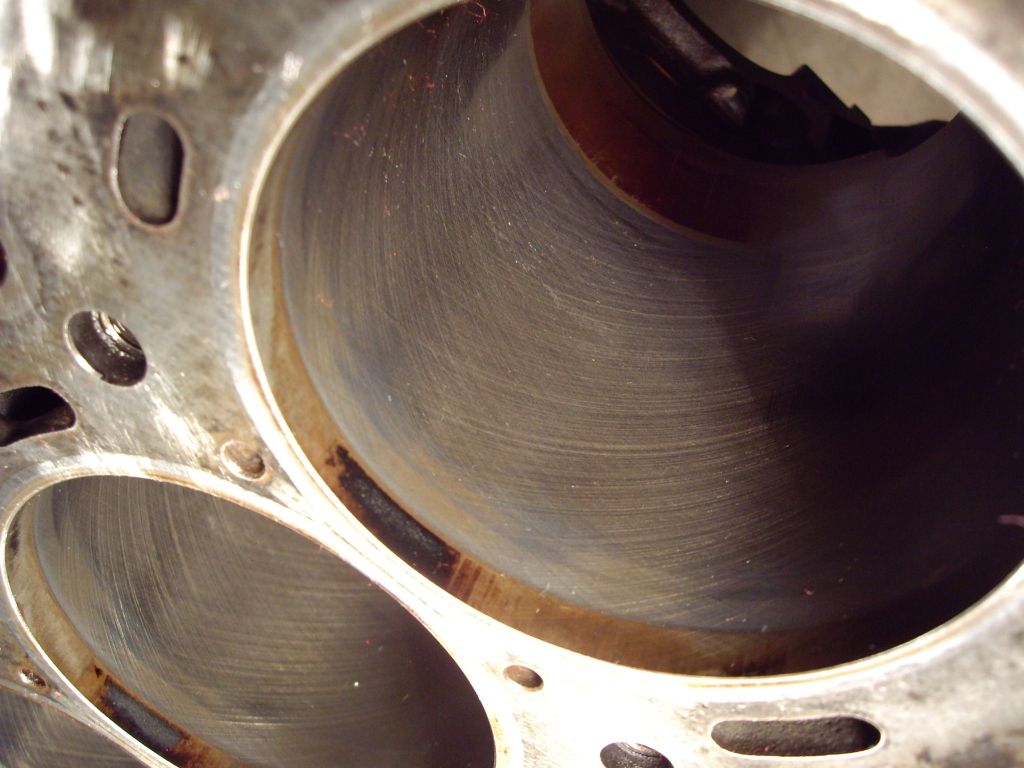

I'm planning on buying a flex-hone (dingle-ball hone), and de-glazing the cylinder walls. I think the cross-hatching still looks pretty good, so it shouldn't need a machine shop hone. What do you guys think?

#4 is the closest one to the camera. The little jagged line near the top of the bore isn't palpable at all... I'm not sure what it is.

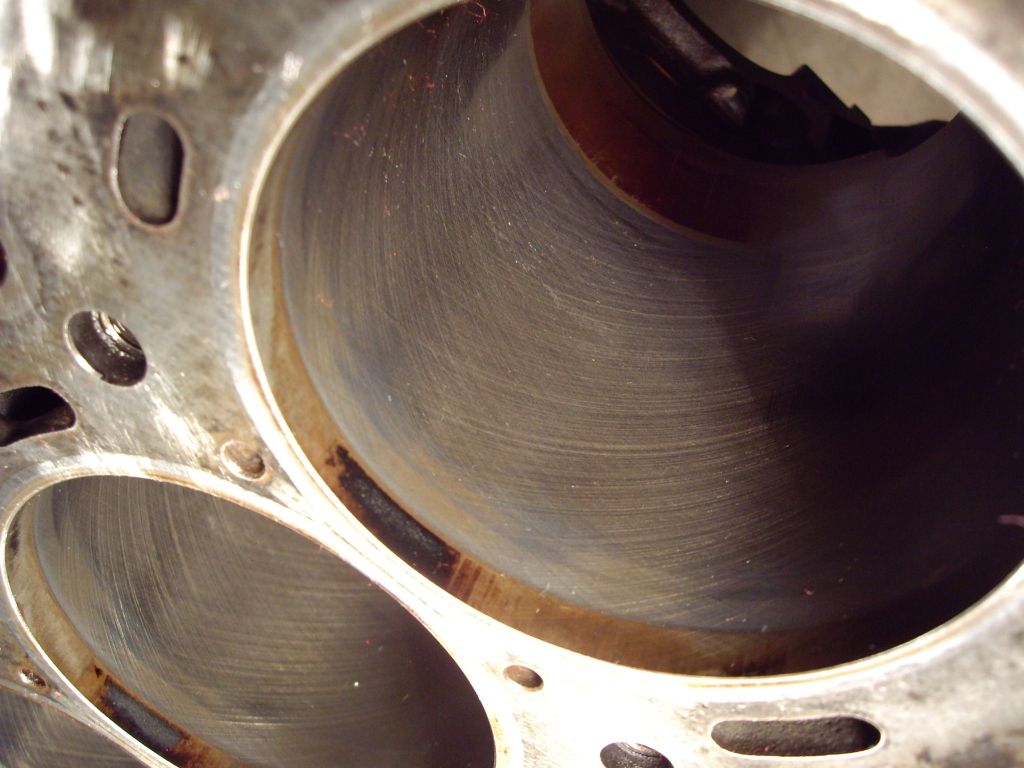

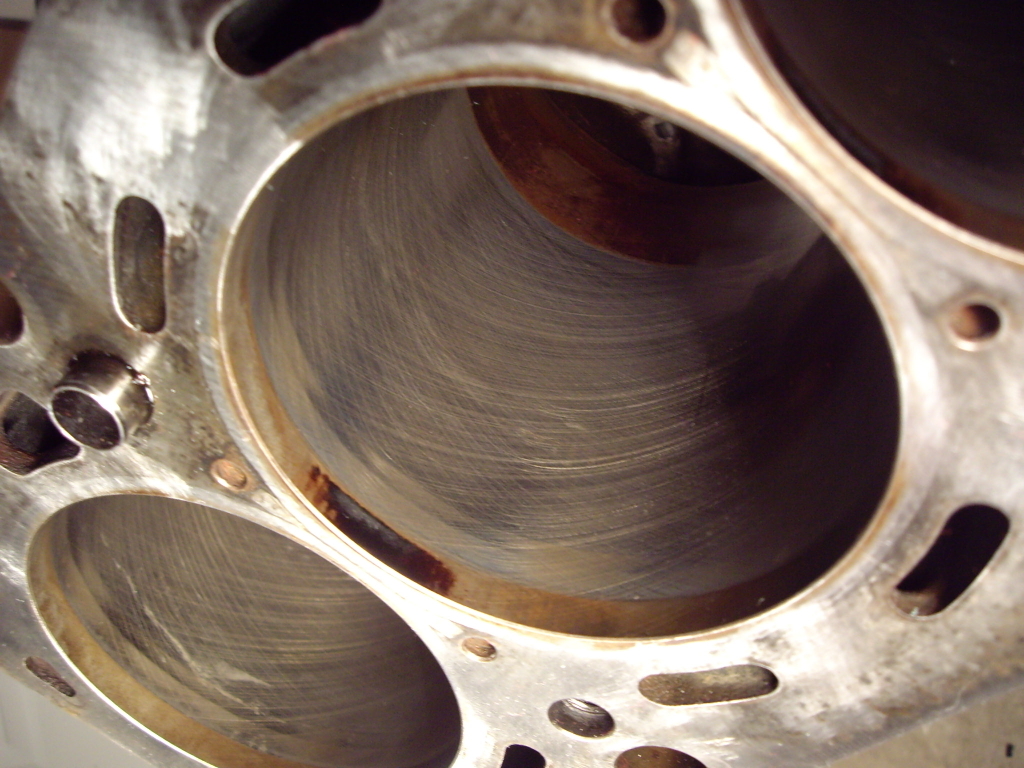

Again you can't feel that little line at all, so I'm thinking the flex hone will clean it all right up.

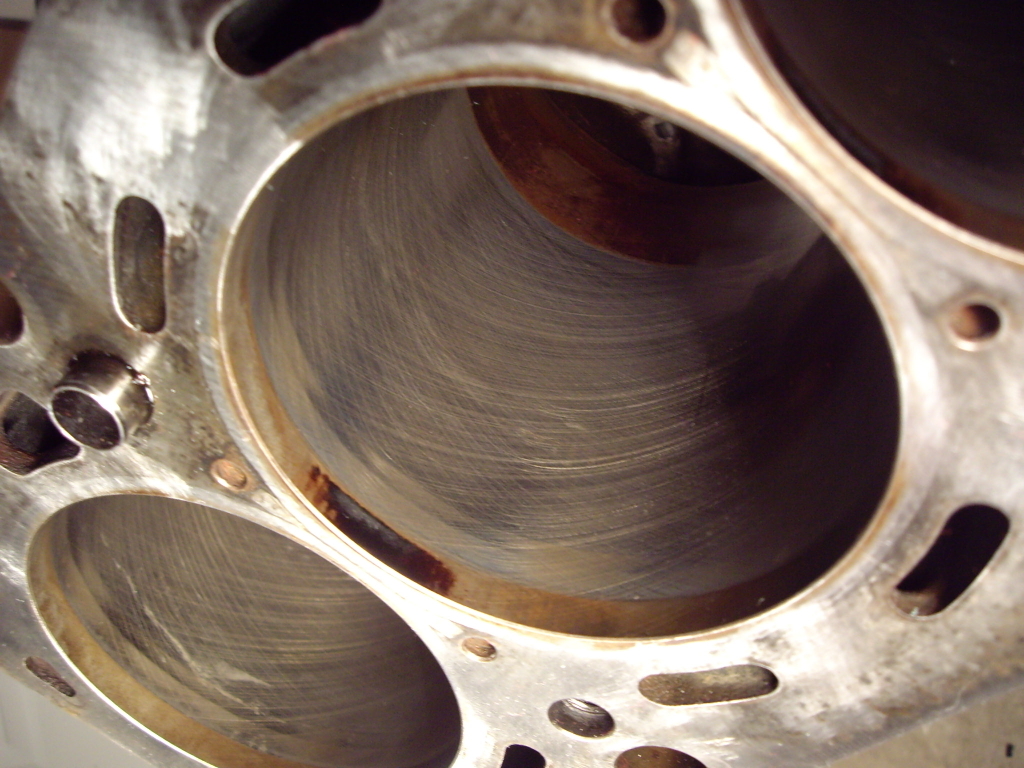

I'm planning on buying a flex-hone (dingle-ball hone), and de-glazing the cylinder walls. I think the cross-hatching still looks pretty good, so it shouldn't need a machine shop hone. What do you guys think?

#4 is the closest one to the camera. The little jagged line near the top of the bore isn't palpable at all... I'm not sure what it is.

Again you can't feel that little line at all, so I'm thinking the flex hone will clean it all right up.

Comment