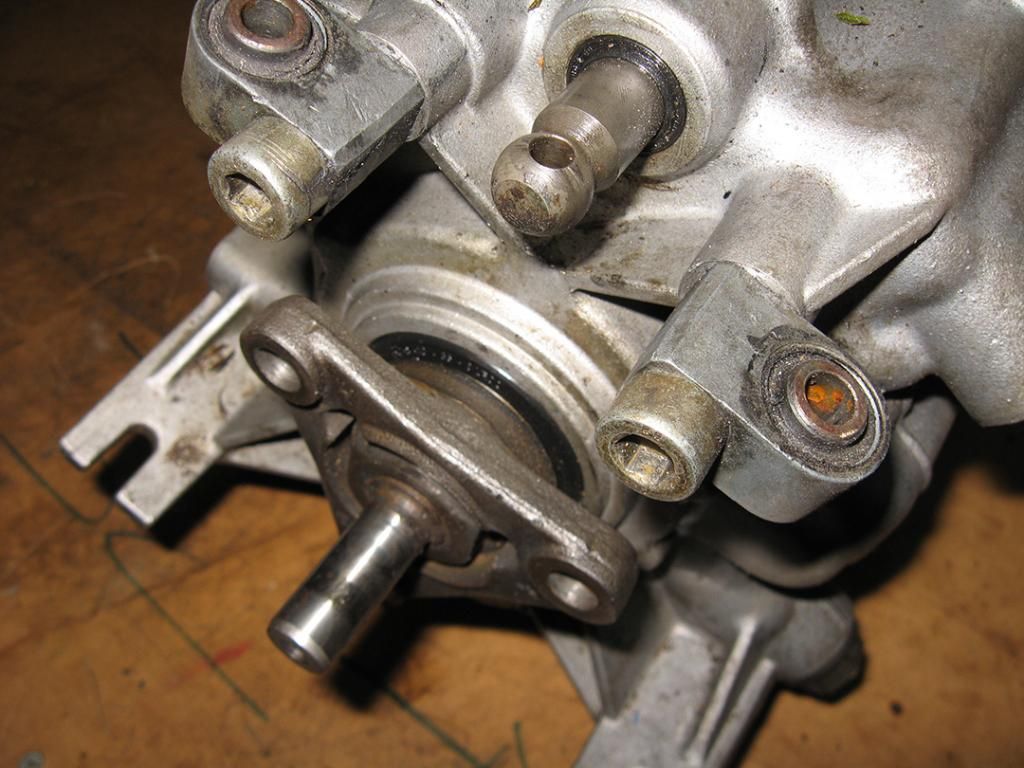

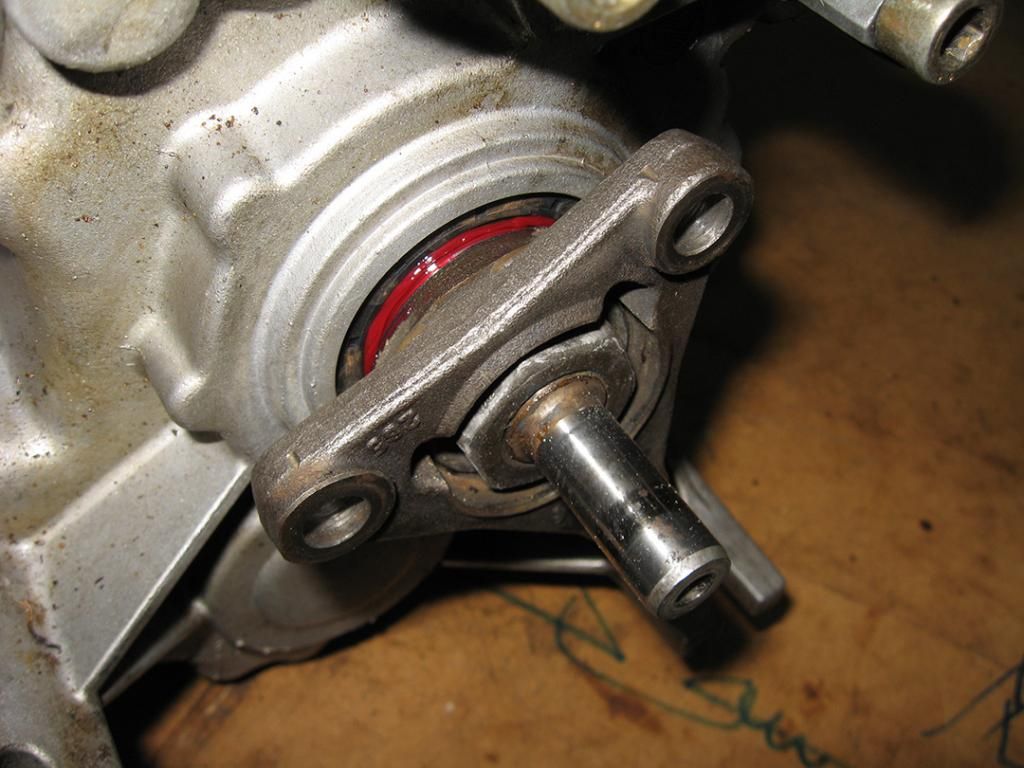

Have a 1987 325e 5 speed coupe. The Tranny is leaking at the rear, and I am going to change the seal. Never dealt with tranny work, and where the driveline attaches is where to start.

I was wondering if its a spring loaded set up in these tranny's, meaning if I take the bolt off at the shaft (rear) do I have to be aware of anything?

Any info would help since I don't know what I am doing anymore, and what's funny is I have owned too many that shit like this makes me feel like a beginner. Which in this case I guess I am.

I was wondering if its a spring loaded set up in these tranny's, meaning if I take the bolt off at the shaft (rear) do I have to be aware of anything?

Any info would help since I don't know what I am doing anymore, and what's funny is I have owned too many that shit like this makes me feel like a beginner. Which in this case I guess I am.

Comment