Careful getting those covers blasted, I had mine done and then it dawned on me after reassembling that the gasket mating surfaces from timing cover to block/ head were no longer a machine finish. Still don't have it running yet so I'm not sure if it has affected anything. Just a thought.

Announcement

Collapse

No announcement yet.

My BMW V8 engine build thread

Collapse

X

-

Yeah, the valve covers will be blasted or tanked...if they get jacked I'll get another pair.Mtech1 v8 build thread - https://www.r3vlimited.com/board/sho...d.php?t=413205

OEM v8 manual chip or dme - https://www.r3vlimited.com/board/sho....php?p=4938827

Comment

-

No problems when blasting the covers, though be careful when heating them - they warp quite easily.

I've gotten 5 M60 / M62 / S62 valve cover pairs done, one pair warped due to too high temp.- E34 M5 (x 2) -

- E30 V8 Cabrio "Kylpyamme" -

- Alpina D10 Touring #33/94 -

+

- E46 318i Touring -

- Toyota Hiace 4wd -

Comment

-

I would probably still go with the v8 personally for a couple of reasons-

1) it's short, keeping the weight closer to the firewall

2) it's got more torque, everywhere, and pulls like a train even in the larger chassis

3) its electronically way easier to run vs s54 and cheaper

4) to my ears it sounds better as well

5) it costs less to maintain from what I've researched

and yep, it costs less than s54 as well, which is a plus. To be honest, I've always wanted a v8 in my e30, so it was just a matter of time.Mtech1 v8 build thread - https://www.r3vlimited.com/board/sho...d.php?t=413205

OEM v8 manual chip or dme - https://www.r3vlimited.com/board/sho....php?p=4938827

Comment

-

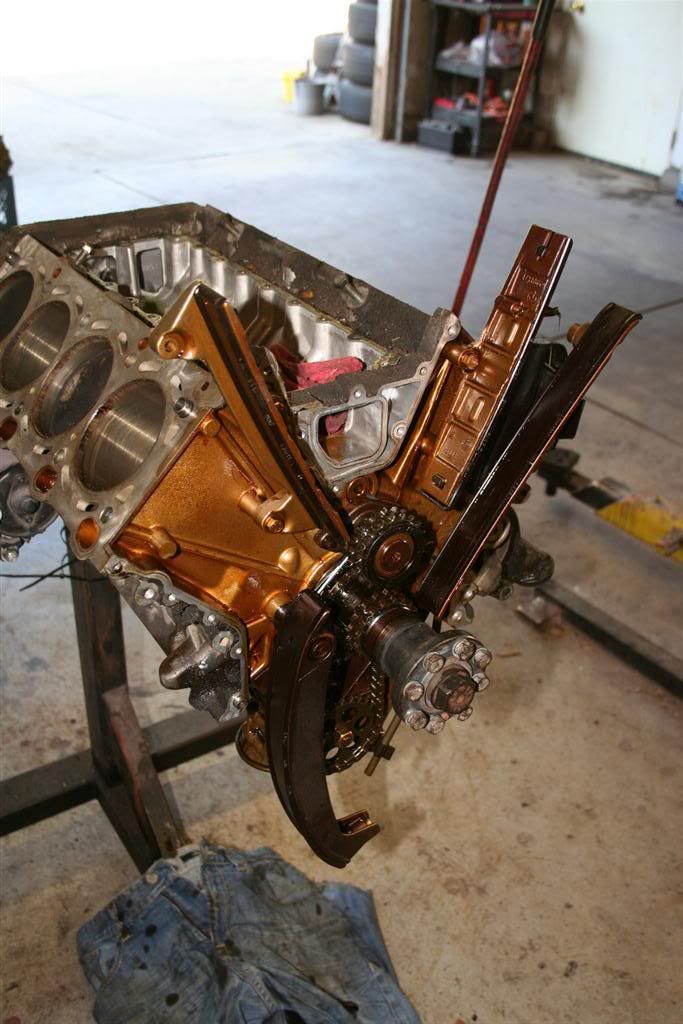

Various metal parts dropped off for blasting/cleaning.

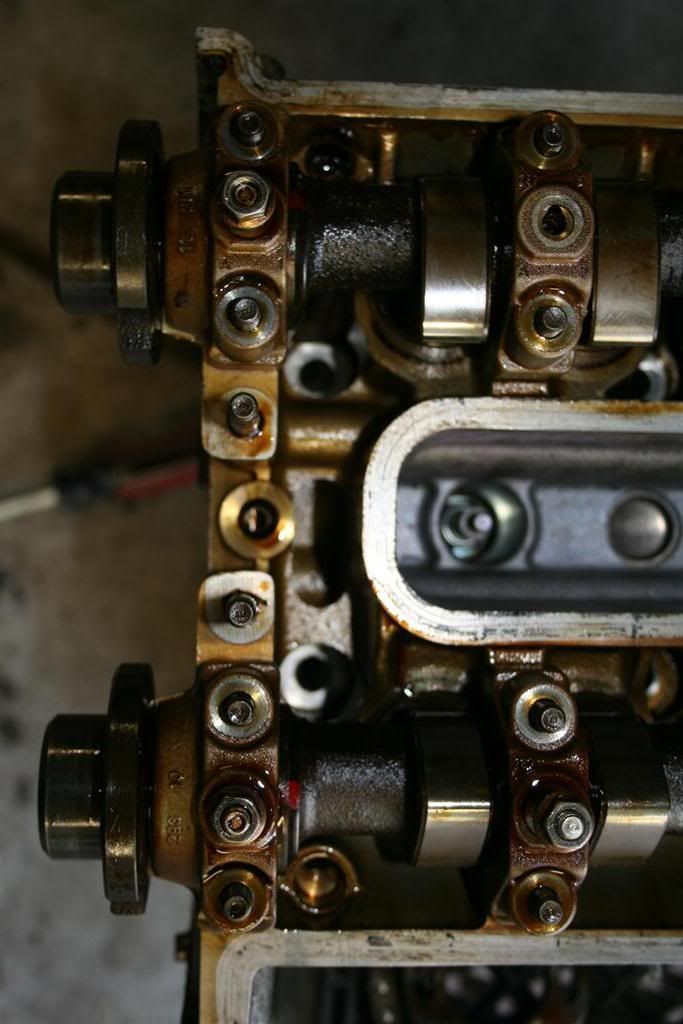

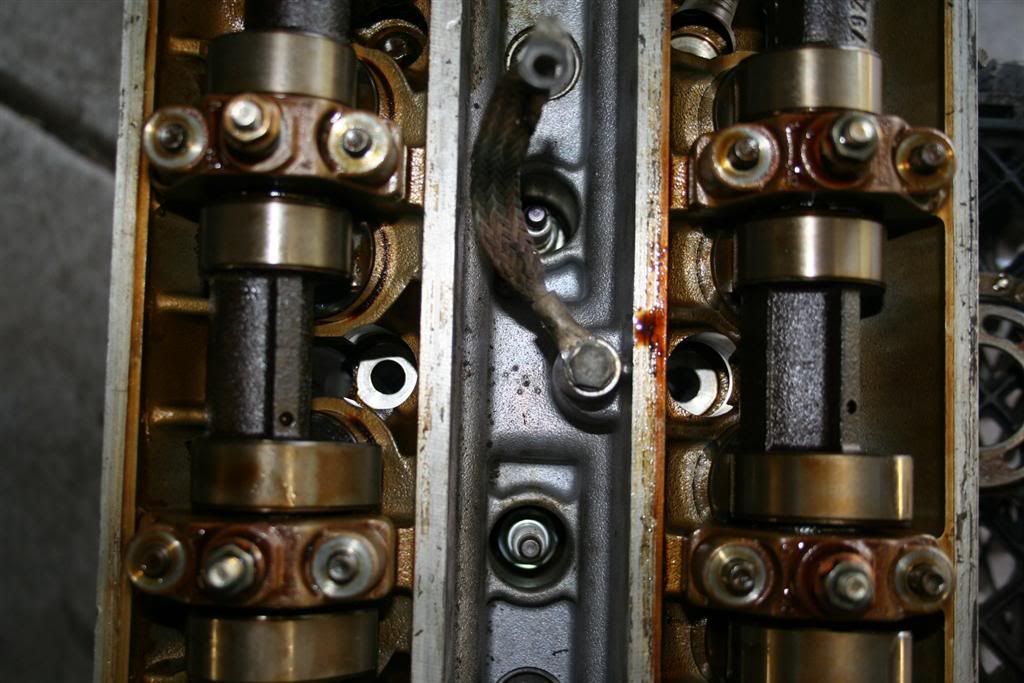

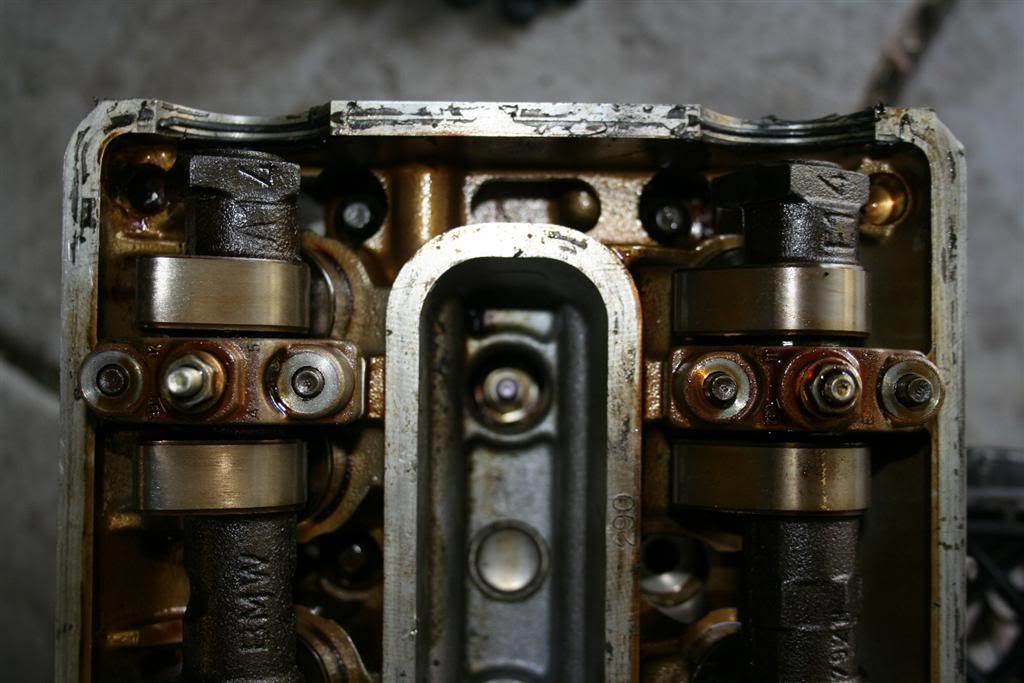

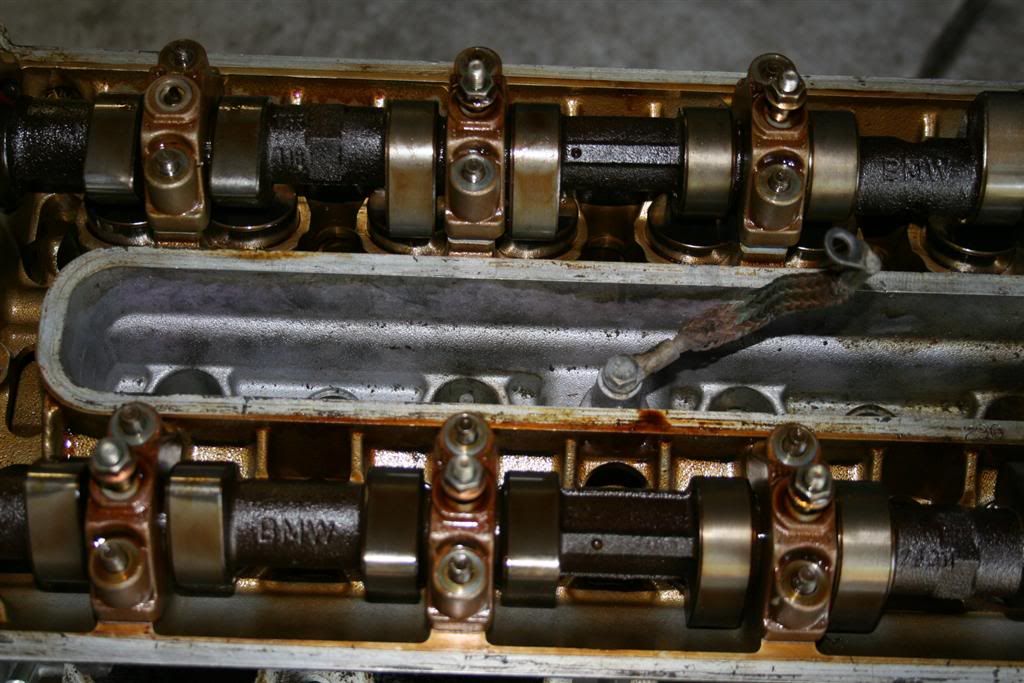

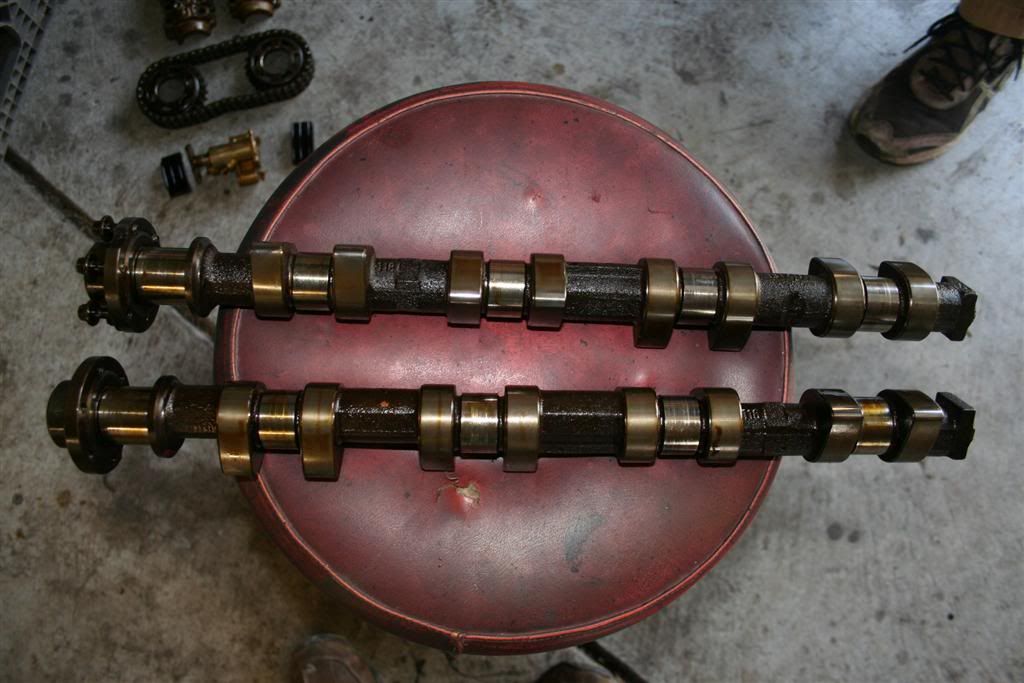

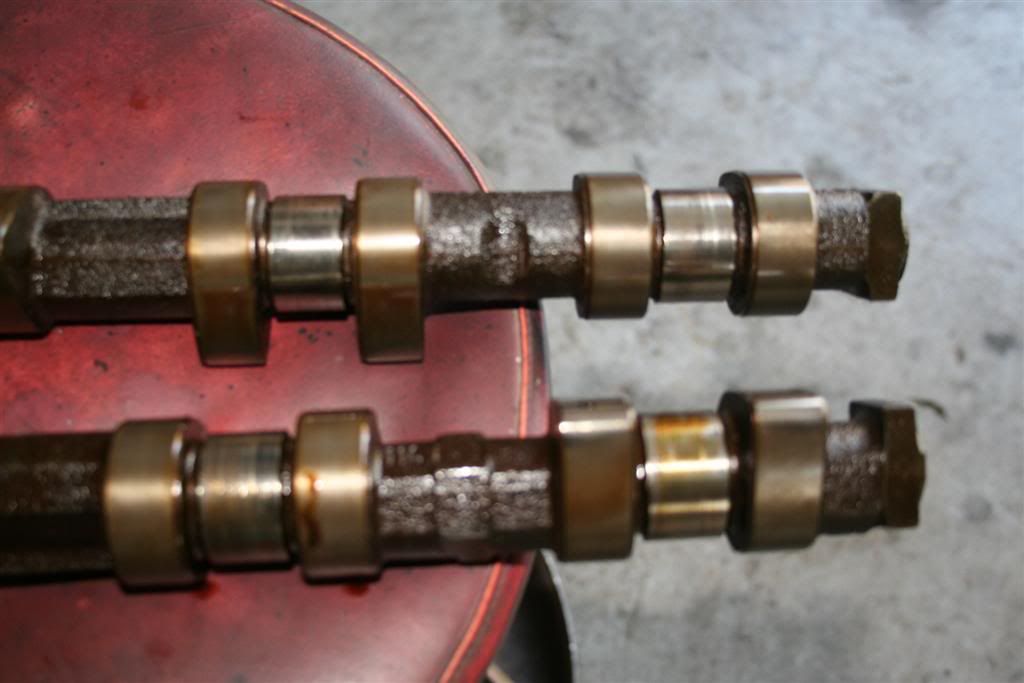

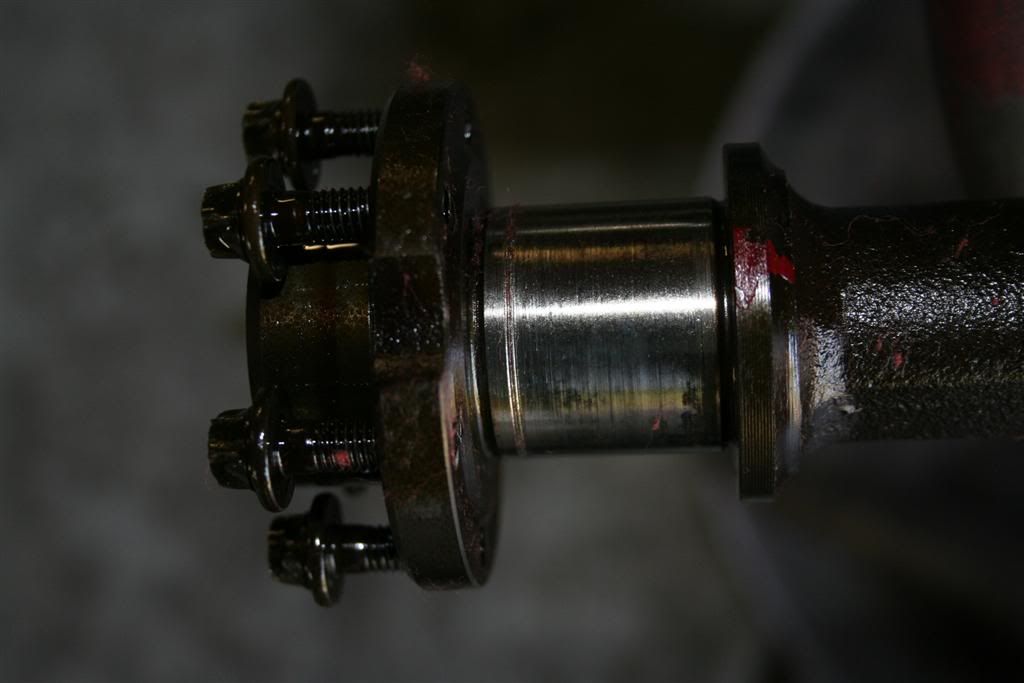

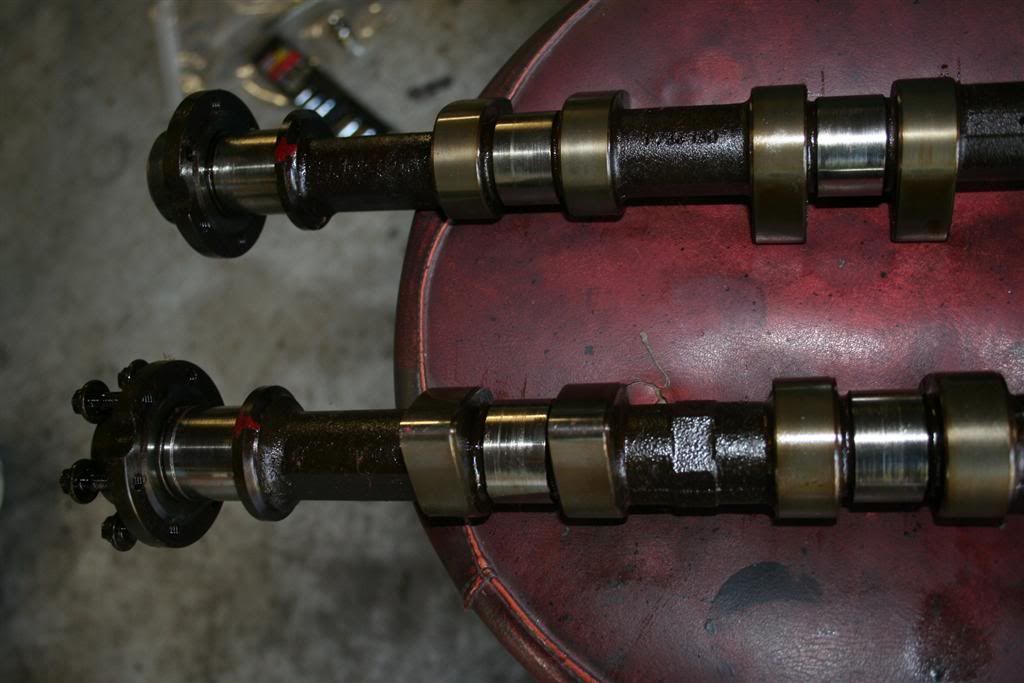

Took the cams out today to inspect, two have some scoring on bearing surfaces , lobes look clean w/o any issues and same with lifters.

I am going to pull two cams out from another engine, and bring the heads over to the machine shop next weekend for a rebuild.

Pics.

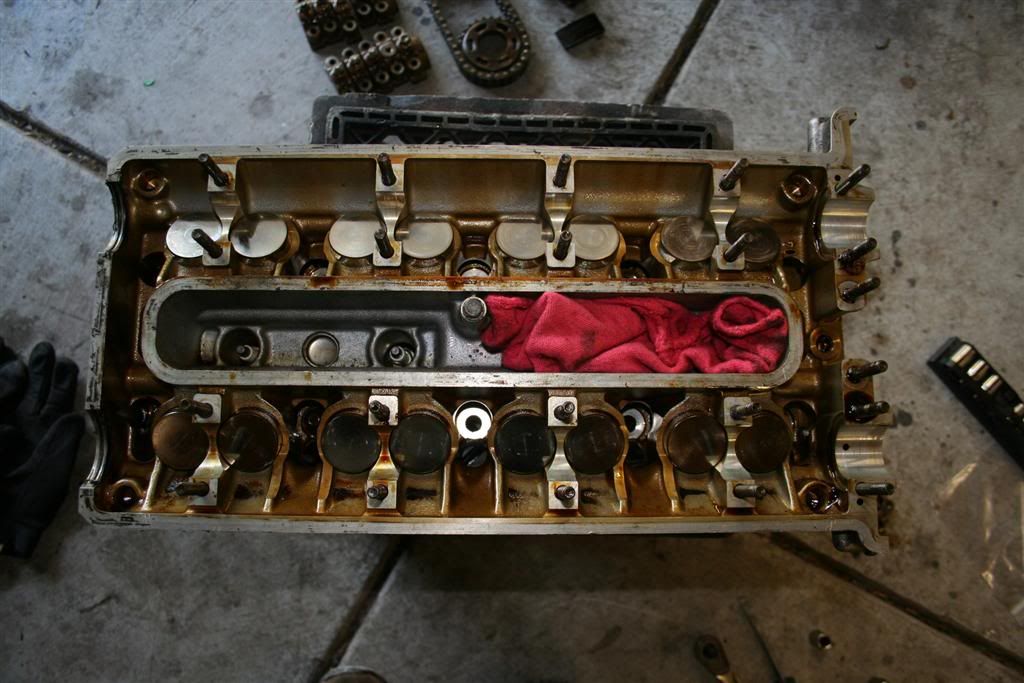

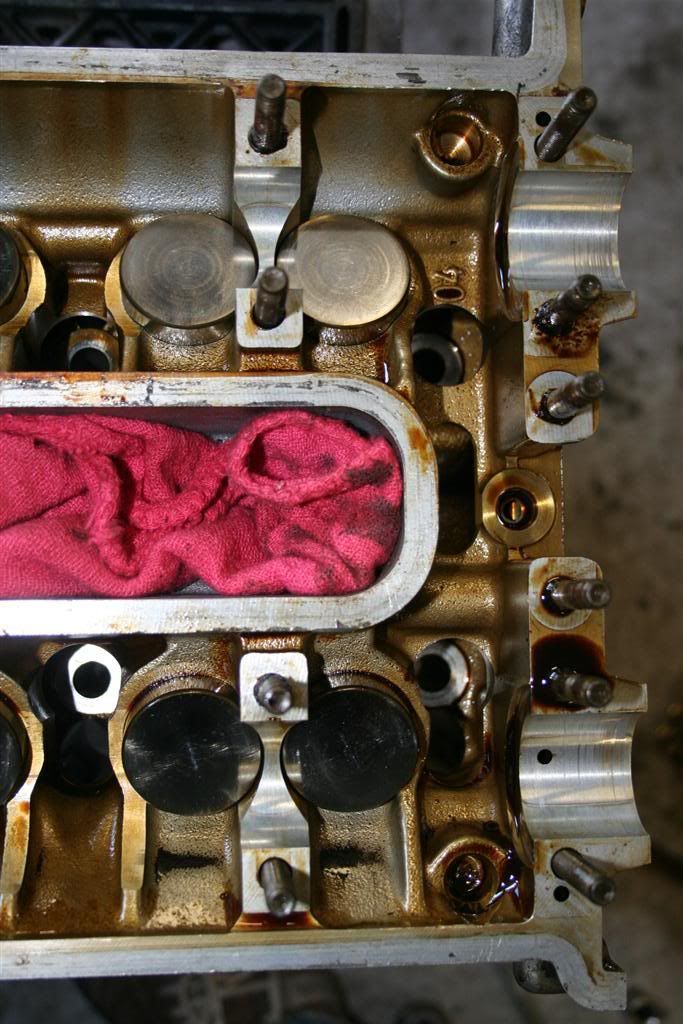

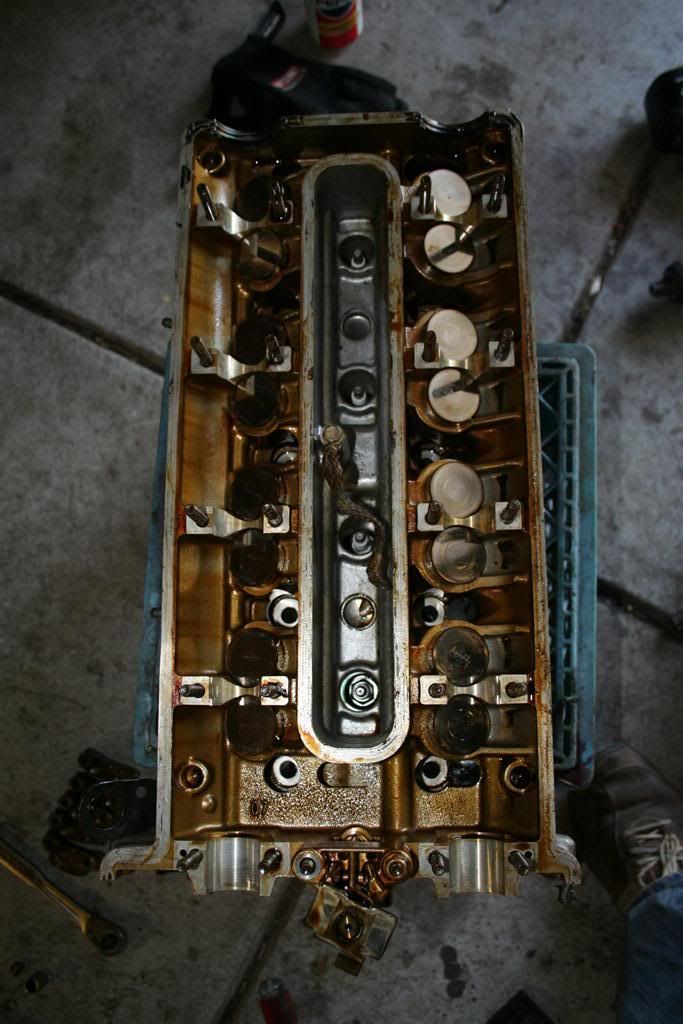

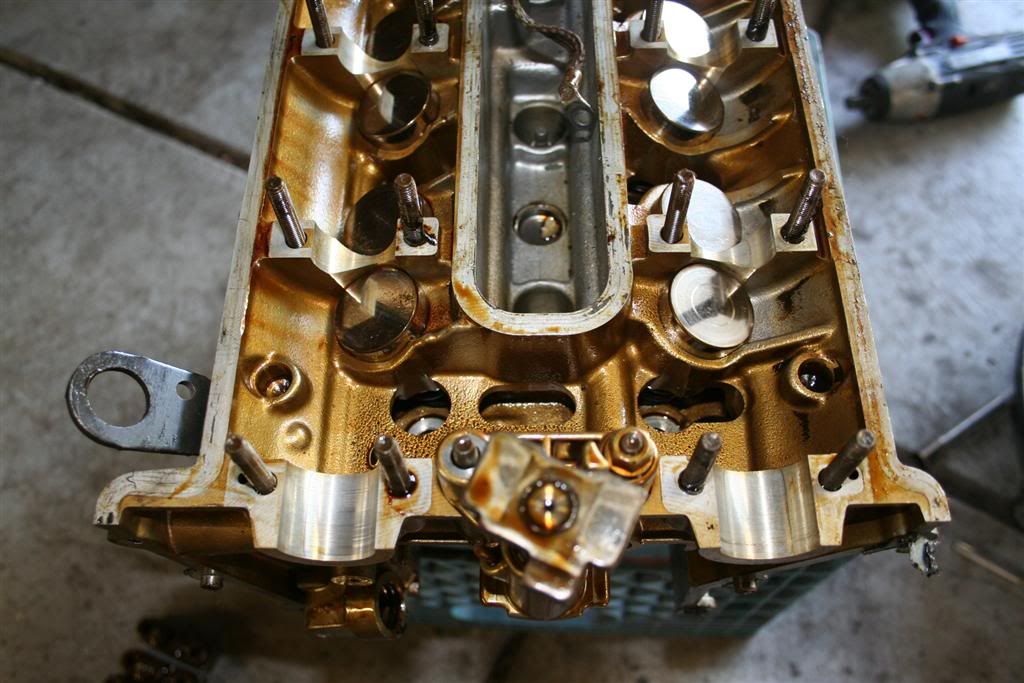

Passenger side head.

cams pulled

camshafts

cam/timing hardware

cams from driver side head

problem area

head

To do -

get cams/lifters/caps

mark/package each lifter.

research catcamsLast edited by Jean; 12-11-2011, 03:29 PM.Mtech1 v8 build thread - https://www.r3vlimited.com/board/sho...d.php?t=413205

OEM v8 manual chip or dme - https://www.r3vlimited.com/board/sho....php?p=4938827

Comment

-

I am sure they can be, but It's just cheaper/easier to grab another set.Mtech1 v8 build thread - https://www.r3vlimited.com/board/sho...d.php?t=413205

OEM v8 manual chip or dme - https://www.r3vlimited.com/board/sho....php?p=4938827

Comment

-

This is a little off topic...

Originally posted by Jean View PostDual row timing chain/guides

Bimmerforums is the preferred online BMW Forum and community for BMW owners. At Bimmerforums, you will find technical how-to information maintenance specifics audio advice wheel and tire combinations and model specific details not found anywhere else. Our professionals are here to help make sure you find the answers you need to your questions and our community is here to help other brainstorm ideas for the future.

Bimmerforums is the preferred online BMW Forum and community for BMW owners. At Bimmerforums, you will find technical how-to information maintenance specifics audio advice wheel and tire combinations and model specific details not found anywhere else. Our professionals are here to help make sure you find the answers you need to your questions and our community is here to help other brainstorm ideas for the future.

Originally posted by razahyde

finished number too, notice the clock again, now its am.

So the S62 and M62 both use the later U-shaped chain guide...

Is it feasible to install the M60 idler sprocket and guides in an S62 in place of the U-shaped guide?

The S62 already has a dual row chain. Are the chains the same pitch? The same length? If the chains are the same length and all the bolt holes are still in the block, I'd expect the M60 parts would just bolt in.

Thoughts?

Comment

-

So I have both heads in my daily driver, was going to drop them off this saturday but they closed early. Tomorrow or tuesday I'll drop them off, will start with getting them tested / cleaned and go from there.

At the minimum will go with new valve stem seals, and pending price may go further. I've heard from 24v guys that the retainers sometimes fail, is it worth getting new ones?

I am thinking these should be replaced yes/no ?

11 VALVE COLLET D=6 ? 11341461405 $1.34

Does anybody know what's included in this kit?

05 REPAIR KIT VALVE SEAL RING 2 11349063193 $70.17Last edited by Jean; 12-18-2011, 11:44 PM.Mtech1 v8 build thread - https://www.r3vlimited.com/board/sho...d.php?t=413205

OEM v8 manual chip or dme - https://www.r3vlimited.com/board/sho....php?p=4938827

Comment

-

Heads dropped off on my lunch break.Mtech1 v8 build thread - https://www.r3vlimited.com/board/sho...d.php?t=413205

OEM v8 manual chip or dme - https://www.r3vlimited.com/board/sho....php?p=4938827

Comment

-

Heads done.

Now I need to inspect each bore.

Now to track down this "A video titled "M60 Engine Diagnosis" is also available which further highlights the M60 engine diagnosis procedures"

The article below makes it sound like it's totally OKAY to take the pistons/rings OUT for measuring and then re-install them if they measure fine w/o installing new rings.

Interestignly it does not say anything about using new rings or anything, I bet they never did that and replaced the lower block with already installed new crank/rods/pistons/rings from the factory. But it seems that to trully inspect it you do have to remove the pistons and measure stuff and then re-install if ok.

Am I reading this right?

Originally posted by GarrettSR5GROUP 11

Engine

Bulletin Number

11 11 95 (4305)

Woodcliff Lake, NJ

October 1995

Product Engineering

The DME EPROM programming update Service Action outlined in Service Information bulletins 12 06 95 (4258) and 12 09 94 (4132) must be performed on all affected M60 powered vehicles. The DME programming update will not affect a vehicle's idle quality. However, it will prevent degradation of idle quality caused by chemical reaction of high sulfur content fuels with the cylinder wall material.

SUBJECT:

M60 Engine Diagnosis

MODELS:

All with M60 Engines

Complaints:

1) Excessively uneven idle or

2) Customer requests assurance that his/her M60 engine is operating within BMW specifications.

Note:

A certain fluctuation in idle speed is a normal and inherent design characteristic of the M60 engine as this engine is designed for maximum power output and optimal throttle response while still providing smooth running characteristics. The M60 Engine Test should be performed strictly based on the above mentioned customer complaints of excessively uneven idle or when it is evident that without this test the customer would loss confidence in his BMW. Consequently, the test will only be carried out in a very limited number of cases.

Correction:

A procedure has been developed to diagnose the condition of M60 engines using the BMW DIS tester and is included as of DIS software version 5.0 (see Service Information bulletin 11 12 95 (4307) for further instructions on accessing the M60 Engine Test in DIS). The M60 Engine Test was developed and verified in the field using customer cars with the cooperation of more than 10 BMW dealerships in different parts of this country.

The M60 Engine Test internal thresholds for the "Idle Quality and Pressure Distribution" were correlated exclusively for the M60 engine. The M60 Engine Test should never be performed on any other engine other than the M60 as the results would be false and inconclusive. These internal thresholds are used by the DIS for calculation purposes and cannot be compared with conventional workshop testing equipment. Special tools which include a Snap-On(R) Cylinder Leakdown Tester (tool number 88 88 0 000 118) and a Compression Stroke Indicator (tool number 88 88 0 000 117) will be sent to all dealers via the Automatic Tool Shipment program. See Service Information 04 22 95 (4299). These tools must be used any time a cylinder leakdown test is requested by the DIS Tester when performing the M60 Engine Test. This assures uniform cylinder leakage readings from one technician to the next and avoids possible incorrect readings due to equipment variations.

A video titled "M60 Engine Diagnosis" is also available which further highlights the M60 engine diagnosis procedures.

If the DME EPROM programming update has not yet been performed it should be done at the end of the M60 Engine Test. This will prevent possible incorrect idle quality readings due to a DME which has not yet adapted to the engine.

The M60 Engine Diagnosis Test consist of the following sections:

^ DME fault memory check

^ Electronically evaluating the idle quality; i.e., even engine rotation

^ Electronically measuring cylinder pressure differences; i.e., pressure distribution.

^ Measuring piston ring/cylinder wall sealing; i.e., cylinder leakdown, it needed.

The cylinder leakdown section is only selected by the DIS Tester if the results from the Idle Quality and the Pressure Distribution Test are inconclusive; in other words, if either test fails and the other one passes the present thresholds. The DIS tester gives instructions for the various test steps and requires input of information/test results from the technician using an interactive display screen. The test instructions are located in the "diagnosis test information" displays an the measurements are performed using the "test system" section as indicated.

When all test have been performed and the required information has been input by the technician, the DIS tester will evaluate and compare the results against internally stored values and make a decision on the engine condition.

Conditions:

The following parameters must be met in order to carry out the M60 Engine Test:

^ Engine mileage - at least 3,000 miles

^ Engine at operating temperature - greater than 85°C (185°F)

^ Battery fully charged - greater than or equal to 12.3V

Note:

The M60 Engine test will be delayed automatically until the operating temperature and battery voltage specifications are met.

If the DME cannot be identified by the DIS Tester due to a previous EPROM change. the DME EPROM programming update Service Action outlined in Service Information bulletin 12 06 95 (4258) or 12 09 94 (4132). must be carried out first to continue the M60 Engine Test

Procedure:

After the individual idle quality, pressure distribution, and if needed, cylinder leakdown measurements have been performed, a screen printout must be made as indicated in the test instructions. All printouts should be kept with the repair order in the Vehicle History file.

Note:

While performing the Idle Quality Test, an "Error Message - Fault Code 200" may be displayed on the DIS screen due to a glitch in the current software. If this message is displayed the "Continue" button should be selected which will resume the M60 Engine Test.

Screen printouts required when performing M60 Engine Test:

IDLE QUALITY TEST WORKSHEETS

SINCE THE INDIVIDUAL WORKSHEETS ONLY SHOW INTERMEDIATE M60 ENGINE TEST RESULTS THEY SHOULD NOT BE GIVEN TO THE CUSTOMER.

Troubleshooting:

A) If a CUSTOMER COMPLAINT of "EXCESSIVELY UNEVEN IDLE" is received and the DIS tester display reads - "POTENTIAL COMPLAINTS OF POOR IDLE WHEN THE ENGINE IS NOT SUBJECTED TO A LOAD ARE NOT DUE TO EXCESSIVE WEAR OF THE PISTONS OR CYLINDER WALLS", the following check list should be reviewed to further troubleshoot the rough idle condition; use the DIS tester to perform the following checks, as appropriate, to identify problems areas before proceeding with disassembly. Follow the DIS diagnostic procedures.

^ Assure the DME Control Unit has gone through the initial adaptation phase; if necessary, drive the vehicle under various load conditions (idle, acceleration, normal road speeds, etc.) after the DME EPROM programming update Service Action has been performed.

^ Using the preset measurement section of the DIS, check that secondary firing voltage is present on all cylinders. If not, check individual spark plugs and ignition coils

Note:

If the Idle Quality Test indicates that a particular cylinder has a higher value compared to the other cylinders, the spark plug/ignition coil of that cylinder should be checked first.

^ Check engine for unmetered air leaks using the DIS Tester. Follow the DIS Diagnostic Procedures.

DME Status Request nominal values:

- Oxygen Sensor voltage = should fluctuate between 0.01... 0.9V

- Oxygen Sensor integrator fluctuates around 1.0

An integrator voltage which remains at greater than 1 indicates the presence of an unmetered air leak.

- Idle-air adaptation = -7... +5 Kg/h

The idle-air adaptation ideal value should be approximately 0 Kg/h at idle.

- Mixture adaptation = -20%... +20%

The mixture adaptation values should be approximately 0% at idle.

Note:

On vehicles with M60 engines produced prior to 5/93, the crankcase vent valve cover located on the rear of the intake manifold should be checked for proper installation of the vacuum plug and the fuel pressure regulator vacuum hose (see illustration).

If the vacuum plug is present and the vacuum hose for the fuel pressure regulator is attached to its fitting on the crankcase vent valve, the crankcase vent valve does not need to be replaced.

If the vacuum plug is missing and/or the vacuum hose is disconnected, the crankcase vent valve and plug must be replaced.

B) If the DIS tester display reads - The measurements indicate the need for engine disassembly and further inspection", the procedure below should be followed:

^ Remove the engine as per repair manual, group 11

^ Remove the cylinder heads and inspect cylinder bores for the crosshatch hone marks.

1) IF THE CROSSHATCH HONE MARKS ARE VISIBLE UP TO THE TOP LAND (see illustration S1194023), all pistons must be removed from the block and the top compression ring end gap measured.

Note:

When measuring the top compression ring end gap a outlined in the repair manual,group 11,the piston ring should be inserted into the respective cylinder bore approximately 8mm from the top of the cylinder block sealing surface. (Hint: To position the piston ring for measuring, install the piston ring into the top of the bore and use a piston turned upside down to slide the ring squarely (8 mm) down into the cylinder bore.)

All vehicle data, dealer/technician name and piston ring end gap measurements must be noted on a Quality Control Information Sheet "Pink Sheet" and sent to BMW of North America in Montvale, NJ. A copy must also be kept in the Vehicle History file.

If all of the top compression ring end gaps measure less than 0.5 mm (0.20 in.), the cylinder bores/piston rings are not worn and the engine should be reassembled. In this case the valves/valve seats should be checked for leakage and the valve seats remachined as necessary.

If any of the top compression ring end gaps measure greater than or equal to 0.5 mm (0.20 in.), replace all piston rings and reassemble the engine.

2) If the crosshatch marks are completely or partially worn away down to the first compression ring Top Dead Center (TDC) change over point or beyond a new shortblock should be installed.Last edited by Jean; 12-23-2011, 12:49 PM.Mtech1 v8 build thread - https://www.r3vlimited.com/board/sho...d.php?t=413205

OEM v8 manual chip or dme - https://www.r3vlimited.com/board/sho....php?p=4938827

Comment

Comment