e34 remote brake booster install

Collapse

X

-

Looks great.....clean after having seen the full installation. What's next in your checklist now that the hardest part is over? -

Did some more work on the booster setup. Only thing left to do is finalize the upper booster bracket on the top of the wheel well.

Leave a comment:

-

There are many ways to implement a brake setup just as there are many ways to solve a math problem.

i like differences and the plug-and-play aspect of Justins setup and i love the pics, so keep them coming.Leave a comment:

-

Leave a comment:

-

I don't know why, I'm assuming some sort of impact.

Solution(s) is they key word there. There's more then one way to do some things, and each has pros and cons. For me, with what I have access to, this was the easiest and cheapest solution.Leave a comment:

-

Oh, that's very suprising indeed. May I ask how they broke?

Yes this is getting ridicilous.I know you're a "my way is the only way" kind of person, but this is a little ridiculous, don't you think? Why does it matter, at all?

All I'm trying to do is trying to help you guys out to find the optimal solutions and help fellow V8 swappers forward.

Making a pocket that collects water & dirt while doing additional work in the first place is not optimum from my point of view and thus I just wanted to point out that there'd be easier solutions as well.Leave a comment:

-

I don't know/trust anyone locally to do that kind of work on my car. I'm sure I could find someone if I looked hard enough, but again, why, when I can just notch the frame rail?

Actually, 2 so far, hence the reason for just buying a new one.

I know you're a "my way is the only way" kind of person, but this is a little ridiculous, don't you think? Why does it matter, at all?Leave a comment:

-

Ummm.. drive to nearest TIG-welder (5min drive), give him 20$ for the job and voila - you've shortened booster-support in your hands. ;)

How many broken brake booster support arms have you run to .. ? :)Leave a comment:

-

Another reason is I'd rather modify the chassis then modify the parts I'm installing. That way, for future repair work, I can just bolt parts in, as opposed to having to make stuff again.

I like your upper bracket on the wheel well. I'll probably cut mine out and do something like that. simple and clean.Leave a comment:

-

Doesn't really matter either way, does it?

Modding the booster bracket would require that I purchase a tig welder, learn to tig aluminum, then have one of my first welding jobs be a critical brake linkage component.

Took me an hour or so to mig weld the frame rail with the mig welder I already had, and knew how to use.

That's why I chose that option.Leave a comment:

-

I'm wondering why you didn't just shorten the brake-booster bracket and instead cut & welded the frame rail ... ?

Couple of pics of the latest brake-linkage I made;

Leave a comment:

-

Looks good... having that core support removable is the bees knees! 1 picture the motor is out the next it's in... now that's fast!;)

GareyLeave a comment:

-

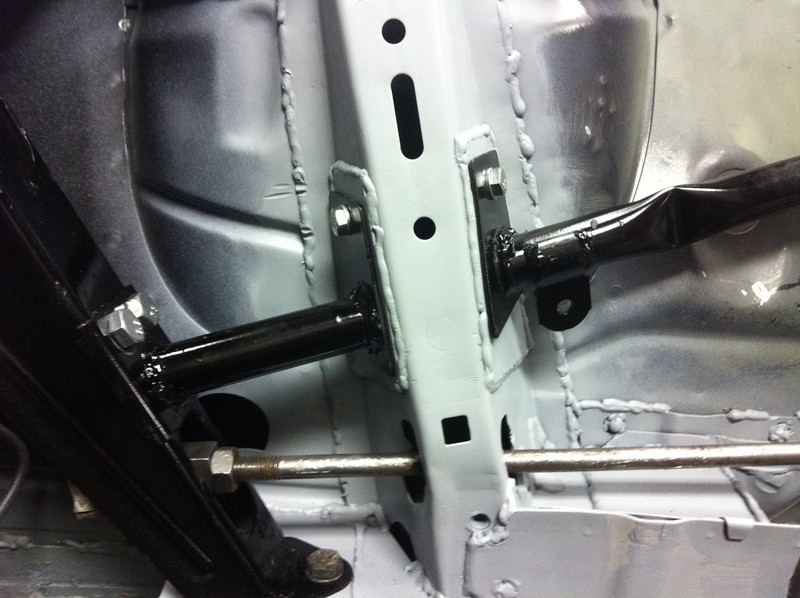

My booster bracket is installed. I notched the frame rail, boxed it in, and welded captive nuts for the bracket. I shortened the linkage rod from ~18" to ~13". Everything seems to be working perfect, I'm getting full linkage travel, no binding anywhere, and no flex in any of the brackets. I'm still planning on connecting the booster bracket and knee bracket somehow, probably a modified version of the stock arm, but possibly just butting them up against the strut tower support instead of a direct connection, since I don't want to remove too much material from the strut tower support. I also want to box in the lower knee bracket support, but I'll wait until the strut tower support is installed as I'll probably just weld it all together.

Leave a comment:

-

Well, you don't have to be an engineer to do this, you need to have the drive, and you're doing great.

As for my pedal setup, here is what I came up with.

Original pedal setup:

Modification beginning:

Skipping ahead a little (I didn't take many pics of each weld/test/fit)

You can see how I moved the brake pivot point over 3.5" to the left.

For ease of install, I decided to weld some studs on the inside of the original pedal assembly so it would make it easier to install in the firewall.

Leave a comment:

Leave a comment: