Wheel bearing safety question

Collapse

X

-

My Calypso is now in the shop for rear wheel bearings, but I drove it a good while with it making a one sided groan when turning right ( driver side bearing problem). Im having both done as well as some other rear end bushings, RTABS, links, sub frame bushings

But.. I get free labor at an automotive school. Course, its been there 10 weeks so far... LOLsigpic 1987 325isComment

-

How are you drawing the hub out of the bearing to get to the clip? By my reckoning, the hub is in the way and there is no cup nor cap in the HF kit large enough to catch/allow the hub to come out with the bearing; they have to be done separately, correct?I've been using a puller such as the one pictured above, and while not effortless, it was straightforward. Sure there's a clip. Sure the bearings need to be inserted straight, but honestly it was not rocket science. No violence was applied, and not bearing was killed during the process. I did swear at the 20 year old bearing that took some sweat to remove, but reinstall was very easy. I cooled the bearing in a freezer for an hour. It went in like a dream. Method and experience my friend.- Sco

Keep Our City CLEAN & SAFE Do Your PartComment

-

Well I said screw someone else doing it. I wasn't going to pay someone $450 + tax to do something that takes 2 hours and $50 in parts. I borrowed my ex girlfriend's dad's trailer and I am now in Ellensburg with it. I'll get a bearing tomorrow and get after it. My friend works at Schucks here in town and they actually loan out tools. He said they charge my card for the price of the tools, and then give a complete refund when I bring them back within 3 days. So that's a sweet deal, should save me money.

Comment

-

From memory:

- Jack the rear of the car and remove the wheel.

- remove the rear disc, big nut.

- Separate the axle shaft from the rear splined axle

- with the big nut installed and reversed, hammer the splined flange out of the rear hub

- from under the car, hammer out the rear hub out of the bearing

- remove circlip

Now the fun beggins. With the proper puller combination, remove the bearing. An air gun is good to have.Last edited by Massive Lee; 09-18-2009, 05:58 PM.Brake harder. Go faster. No shit.

massivebrakes.com

http://www.facebook.com/pages/Massiv...78417442267056

Comment

-

I just did this twice this past week. The first time took about two hours cause I didn't know what I was doing, the second one took less than 40 minutes.

Went like this:

Removed wheel, brakes and axle nut, disconnect driveshaft from differential and press out the axle.

Then use a 30mm socket and 4lb hammer to punch out hub from bearing.The inner race will probably need to be cut off the hub-

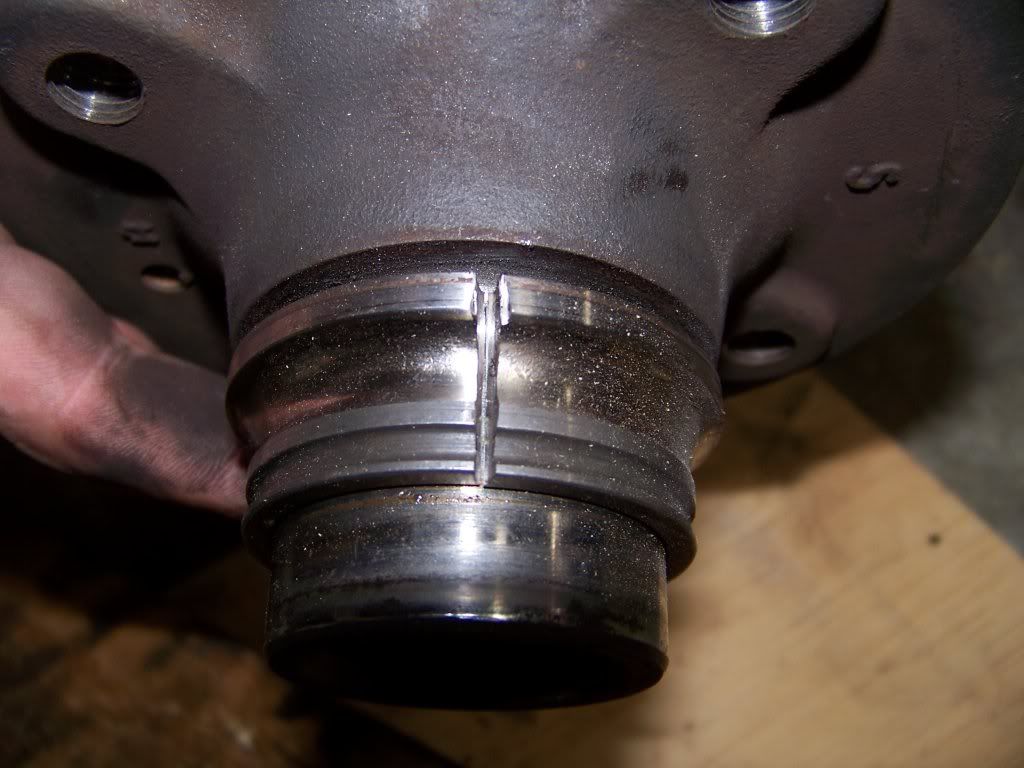

I used a 38mm deep socket and hammer to punch out the old bearing from the trailing arm, here it is rigged in a stationary fashion the the center of the inner race. You can just use your hand to hold the socket at first but then it just harder as the bearing starts to come out, this contraption hold the socket in place and allows you to hammer on the end of the threaded rod to drive the bearing out. This threaded rod can also be used to create a puller to pull the new bearing and hum back into place.

Old bearing race and rubber mallet to fully seat bearing-

Install the circlip and press hub back into new bearing, be sure to support the inner race of the new bearing as you pull the hub in. Reinstall axle, new one in my case, always new axle nut, rotor, caliper, pads and wheel...

'87 325e

'87 325e

sigpicComment

-

Ah, then I'm not crazy. There is not cup or cap in the HF kit to pull the hub; that's not the tool that is used. Thanks for the clarification, Lee.

Thatnks to you too, NJGreenBudd, for the pictures. This is one of those jobs that is written about here and there, but not documented with illustrations.

Between you both, I think this thread may have become sticky worthy in the suspension forum. :)

My challenge right now is a pair of rear arms that are sitting by themselves waiting for new wheel bearings (and bushings). Pounding out the hubs has been troublesome because the arms move with every hit; I don't have the car holding them in place! Thus, I've been trying to find something to press the hubs out and only come up with a hub tamer... and I'm only guessing that will work. Ultimately, I want the arms refreshed and the swaybar mounts reinforced as part of a full refresh of the rear subframe.- Sco

Keep Our City CLEAN & SAFE Do Your PartComment

-

Gald to hear the pics are useful. I was confused at first by the different posts describing wheel bearing removal, it's really not that bad though once you get the idea.

You can go to Sears or Home Depot and buy some 3/8" threaded steel rod, big washers and nuts and literally make the same puller they sell for hundreds of dollars for less than $20. You can use 3" steel pipe caps as a "cup" to pull the bearing into, I used that flange type thing as a back stop and as a flat surface for pulling hub and bearing back in.'87 325e

sigpicComment

-

Are you sure about that? I had some shop tools lent to me. Heavy duty stuff, and they had some hard time as the bearing was stuck. The big washers are 1/4" thick, and the threads are thick too...You can go to Sears or Home Depot and buy some 3/8" threaded steel rod, big washers and nuts and literally make the same puller they sell for hundreds of dollars for less than $20. You can use 3" steel pipe caps as a "cup" to pull the bearing into, I used that flange type thing as a back stop and as a flat surface for pulling hub and bearing back in.Brake harder. Go faster. No shit.

massivebrakes.com

http://www.facebook.com/pages/Massiv...78417442267056

Comment

-

I'm speaking from my personal experience as posted above, your mileage may vary. I'm just saying that there are other options than buying entire wheel bearing kits. You can buy grade 8 nuts and threaded rod and would have nearly the same thing they sell, upgrade to 5/9" rod if you are worried. I'd still use regular nuts instead of grade 8 to have a predictable fail safe point in the system.

There are a few other threads on here which mention building your own puller, search a bit and you'll find them.'87 325e

sigpicComment

-

I did one with the trailing arm out of the car, it wasn't fun but I managed to get it to work. Getting out the hub was relatively easy with a friend. We used the top half of a craftsman aluminum jack handle and a sledge. One solid hit and the hub popped right out.Ah, then I'm not crazy. There is not cup or cap in the HF kit to pull the hub; that's not the tool that is used. Thanks for the clarification, Lee.

Thatnks to you too, NJGreenBudd, for the pictures. This is one of those jobs that is written about here and there, but not documented with illustrations.

Between you both, I think this thread may have become sticky worthy in the suspension forum. :)

My challenge right now is a pair of rear arms that are sitting by themselves waiting for new wheel bearings (and bushings). Pounding out the hubs has been troublesome because the arms move with every hit; I don't have the car holding them in place! Thus, I've been trying to find something to press the hubs out and only come up with a hub tamer... and I'm only guessing that will work. Ultimately, I want the arms refreshed and the swaybar mounts reinforced as part of a full refresh of the rear subframe.

'91 318is - OBD-II S52 swapped - E30 M3 5-lug - 5x120 BBS RC090 (E39 Style 5) - TCK D/A coilovers 550/700 [SOLD]

'87 535i - Vacuum brake conversion [SOLD]'93 525iT - 5-speed swap - 320k and counting'09 328xi - 6-speed

Comment

-

If the trailing arm is already off the car you can always just stop by your local garage with the new bearing and have them press the old one out and new one in in a few minutes. Should be a piece of cake with any decent hydraulic press.'87 325e

sigpicComment

-

Okay, I'm bringing this back from the dead. Back when I made this thread I ended up buying the bearing and some grease and renting a puller. I put the car on stands, removed the wheel, caliper and when I took the rotor off, this part just fell out:

The inner part of the rotor was scored and there was metal shavings from this part rubbing on the rotor. It is # 5 on this diagram of the e-brake:

So I have rarely driven this car as I have my truck to drive. I have a partially non-functioning e-brake, so I need to take care of this. I have heard people talk about e-brake rebuild kits but in a quick search, I haven't found any.

So who has done an e-brake rebuild? Did you buy a kit or just buy the parts separately?

Part 2:

I have another; related, issue. I have had a noise since I've owned this car. It comes from the same wheel, and is a "whirring" noise. To me it sounds like a dragging brake. When I bought the car the ebrake never functioned properly (it's an auto so it doesn't matter all that much).

But I am unsure. Now that I know the ebrake isn't functioning or sticking, I am wondering what the noise is. I've replaced the pads on that wheel, and when I take the caliper off, it comes easily, so I assume that the caliper is not sticking.

What does a bad wheel bearing sound like? I've heard descriptions of a bad front bearing, but not a rear. The noise is speed dependent, and is quite annoying. Any input would be appreciated.

Comment

-

Sounds like the wheel bearing going. Mine whirs over 80 Km/h and is annoying as hell. I can't tell if it's my passenger front or rear though. Sitting in the driver's seat it sounds like the passenger rear but when I lean over to the passenger seat while driving it sounds like the passenger front. *sigh*.Comment

-

I'd dig through the e-brake system before blaming the wheel bearing yet. Wheel bearings will get louder when they are loaded and quieter when unloaded. (try driving around a good sweeper and listening to the sound)

Also, push on the sides of the wheel at 12 o'clock & 6 o'clock, if the wheel will move or clunk, you're looking at a loose bearing (same works for tie rods & control arms when done at 3 o'clock and 9 o'clock.)'89 325i track sloot

'01 530i daily

-EnginerdComment

Comment