Depends on the turbo.

And I do recall seeing a LEGITIMATE spec for an electric turbo system once. It was basically a dissociated compressor/turbine, with a generator on the hot side, and a motor on the cold side. IIRC it required around 7kW to run the compressor at full power - but was to be capable of near instantaneous boost under any engine operating conditions, as well as charging the battery while cruising (if boost was not needed). I imagine it'll be found on hybrid semi-trucks long before it shows up in cars (unless it shows up in a 7 series turbo activehybrid first...)

If I can find it I'll post it up, not that this thread gives a fuck.

So I designed a zero lag turbo charger

Collapse

X

-

-

-

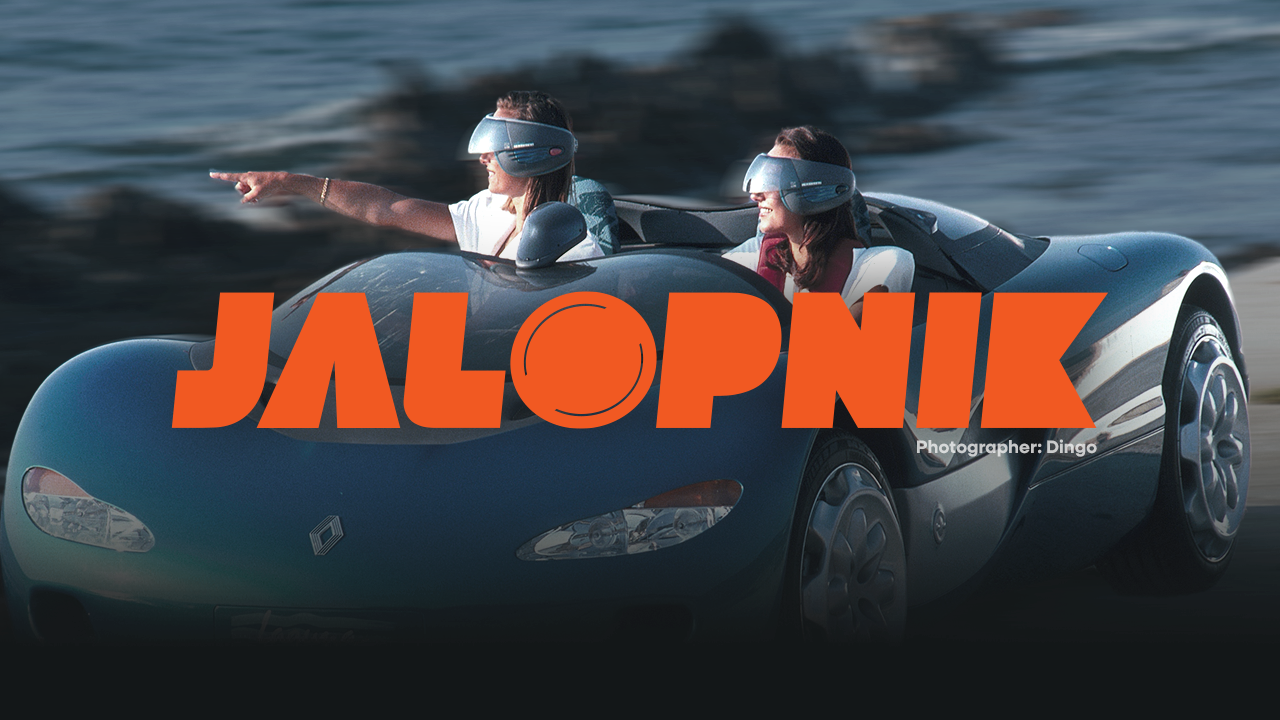

Yes, apparently there is a replacement for displacement. If recently-uncovered patent filings are correct, BMW is working on an electrically-assisted turbocharger that combines a traditional turbo with an electric motor-generator. If it works, the system will let smaller engines produce more power, while performing virtually lag-free.

Yes, apparently there is a replacement for displacement. If recently-uncovered patent filings are correct, BMW is working on an electrically-assisted turbocharger that combines a traditional turbo with an electric motor-generator. If it works, the system will let smaller engines produce more power, while performing virtually lag-free.

Just saying. And no i may not be qualified and i may not have gone to school for it. Its just an idea. Everything started with an idea. And not everybody with the ideas were qualified. I have an idea. I think it will work. i see no harm in trying to make it happen. if it works than it works. If it doesnt oh well. Im going to be having a person who works in intellectual property rights do a patent search to make sure its worth starting and i have a friend with a cnc machine who can make a prototype after said search if its still worth trying. Im not changing how turbos work. Im adding something that i think will help it. The design i have doesnt require a complete redesign of a turbo. Im taking existing technologies and making them work together in a way ive never seen them work together before. You wanna rant and rave about how stupid you think i am go ahead. i still think the idea is worth trying. Doubt me if you like. Its the way of the internet. I just thought it would be nice to share the fact that i had this idea. If you dont like it you dont have to.Leave a comment:

-

You do realize that under max load a turbo spins well in excess of 100,000 rpm right...?Install alternator coil windings in the middle of a turbo, and design the turbo in a way that the internals are always spinning at about engine speed at the minimum (With a lot of computer engineering involved to control the voltage/amprerage output at higher ends) Have it water cooled (E65 style) and voila... no need for an alternator... Just a really expensive turbonater... but the name was already taken :( hahaLeave a comment:

-

Install alternator coil windings in the middle of a turbo, and design the turbo in a way that the internals are always spinning at about engine speed at the minimum (With a lot of computer engineering involved to control the voltage/amprerage output at higher ends) Have it water cooled (E65 style) and voila... no need for an alternator... Just a really expensive turbonater... but the name was already taken :( haha

Leave a comment:

-

Wow... he was so close to getting this done. Actually, both of his Ideas used to be one of mine... He just broke them appart and made them more complicated haha.

Here was my idea while ago.

Install alternator coil windings in the middle of a turbo, and design the turbo in a way that the internals are always spinning at about engine speed at the minimum (With a lot of computer engineering involved to control the voltage/amprerage output at higher ends) Have it water cooled (E65 style) and voila... no need for an alternator... Just a really expensive turbonater... but the name was already taken :( hahaLeave a comment:

-

shark suit for sale

I have the one off shark suit for sale.

I think YOU will need it!

Good for when YOU are Swimming in shark infested Rev3 waters with pockets full of bloody steak.

http://http://youtu.be/WXX40fZEwJ4

JamesLeave a comment:

-

-

What a beautiful thread revival.

My mid '50s ford 860 has 45 PTO HP...

How do you plan on powering the field coil if it's INSIDE the piston? sounds to me like you're gonna need permanent magnets to keep it "simple"...with the engine thing take an alternator apart. you have your coil winding, stator assembly, and the rectifier bridge. little more to it then that but those are the main functioning pieces. the way it works is the coil spinning inside of the stator assembly make ac voltage and the rectifier bridge converts it to dc voltage so the vehicle can use it. just the movement. put the coil inside of the piston and the stator around the cylinder. continuous movement which will make electricity.

Belts are in the 95-98% efficiency range.That sounds super! (...charger)

i can understand a slight savings in not having the belt and friction on the pulleys, but doesnt most of the energy drain an alternator causes come from turning mechanical energy into electrical? You still have that conversion, so unless its amazingly efficient, I dont see how it can be any better. Its not like putting the alternator into the block is just spontaneously creating energy....

source:http://www.cptbelts.com/pdf/misc/ene...efficiency.pdf

That drag is doing WORK. if you move it to a single piston, you've now unbalanced the engine.actually no with the design we have it would simply slide out on the block and a replacement would slide in and lock into place. little more expensive i know but it would save gas mileage and engine wear simply by removing the drag on the belt an alternator creates and while doing so create more horsepower and would also relieve stress on the crankshaft by having less belts.

Modern engines use single serpentine belts.

What about the "stress" on the crank from moving the car? Poor engine

Leave a comment:

-

I hope you were not going to waste your time and money strapping an electric motor to the turbo to spin it before boost build. I remember people working on that almost 10 years ago. I have ideas on how to actually make a lag free boosted engine but it would cost a few thousand dollars to add on to your existing setup. Not worth the cost for a street car and not worth the weight for a race car.Leave a comment:

-

-

Leave a comment: