What is this "muntz" metal used for? Seems like it would have pretty limited application?

-Brian

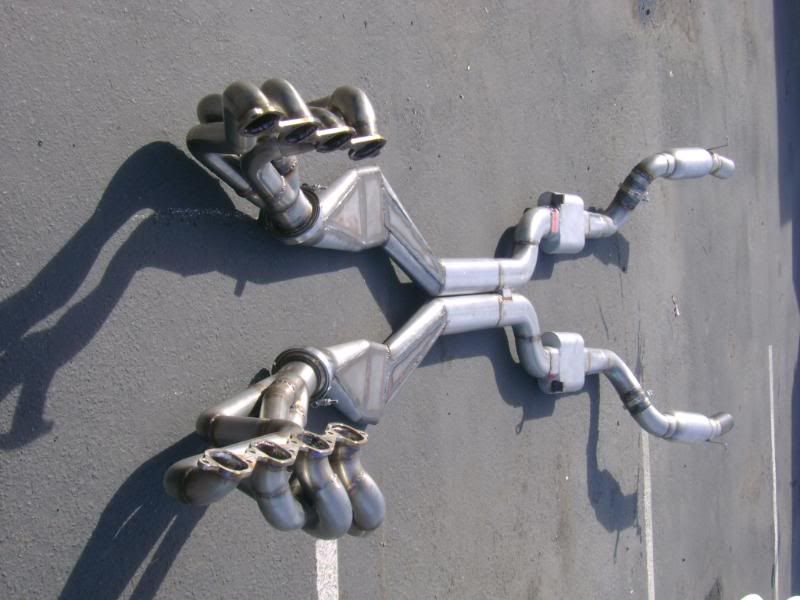

Official Fabrication & Welding Porn Photo Thread

Collapse

X

-

it would be a waste of your time to not learn that skill. it would be like spending a year in mexico and not learning spanish. git on that son!

oh, that would be muntz metal. 60% copper, 40% zinc and a trace of ironLast edited by flyboyx; 05-06-2011, 11:41 AM.Leave a comment:

-

I dont do the welding I just am a Sales Engineer. I dont like mixing auto stuff with work .... I guess I could get one of the guys to teach me during work :)Leave a comment:

-

HolyCrap... And you want me to show you how to weld...? :roll:

not automotive related but Ill contribute...

I work in a shop that builds custom ASME code pressure vessels and Space Thermal vacuum simulation chambers so the weld quality needs to meet stringent requirements.

here are some pics from today:

We are building our vacuum chamber that we will be doing titanium welding in:

vacuum tight weld to hold up to 10x10^-12 Torr space vacuum

ASME code jacketed pressure vessel

ASME code pressure vessel head with an 4ft ID x11in thick flange. Head outer weld required 60 passes on the outside and 35passes on the inside with a dye penetrant check and radiograph to make sure there are no inclusions at all. The weldment had to remain heated so imagine welding in an oven...

Vacuum flange

"Un-Weldable" Munze metal, we developed a weld proceedure and are first to sucessfully weld Munze metal and get it structually certified by the state of CA

Leave a comment:

-

-

not automotive related but Ill contribute...

I work in a shop that builds custom ASME code pressure vessels and Space Thermal vacuum simulation chambers so the weld quality needs to meet stringent requirements.

here are some pics from today:

We are building our vacuum chamber that we will be doing titanium welding in:

vacuum tight weld to hold up to 10x10^-12 Torr space vacuum

ASME code jacketed pressure vessel

ASME code pressure vessel head with an 4ft ID x11in thick flange. Head outer weld required 60 passes on the outside and 35passes on the inside with a dye penetrant check and radiograph to make sure there are no inclusions at all. The weldment had to remain heated so imagine welding in an oven...

Vacuum flange

"Un-Weldable" Munze metal, we developed a weld proceedure and are first to sucessfully weld Munze metal and get it structually certified by the state of CA

Leave a comment:

-

dam pipe fitting is its own beast all together....+ working outdoors...ouch..get er done!!!right now???? Mile and half of .219 wall 6" OD natural gas gathering line in the southern hills of PA. All last winter 10 miles 500 wall 30" in the norther hills of PA. With some little fab and compressor station work in between, Been fucking busy as shit since last fallLeave a comment:

-

Metals turn blue when heated so the thickness and how much heat applied will effect the blue-ness of the weld area. The pictured below with the super blue piping and exhaust is most likely a full titanium exhaust. Titanium turns ridiculously blue when welded or just heated.why are some spots on the TIG welds blue and others not?

i need to learn how to weld big time.. i have so many things i want to make for my E30 and the only missing link is a welder. providing i had the time i could easily spend countless hours working on something millimeter by millimeter all day long, i do it already with other things. kinda like once u get going ur in the zone and dont want to stop lol

my contribution from google:

Leave a comment:

-

right now???? Mile and half of .219 wall 6" OD natural gas gathering line in the southern hills of PA. All last winter 10 miles 500 wall 30" in the norther hills of PA. With some little fab and compressor station work in between, Been fucking busy as shit since last fallLeave a comment:

-

whatcha buildin?gawd damm. coming from a guy that makes a living looking a welds all day. I must say there are some damm fine welders make the shit pictured in this thread.

Fuck I wish I had some of these guys on the job I am on now for christ sakes I would be really nice to look at clean welds for a whileLeave a comment:

-

-

gawd damm. coming from a guy that makes a living looking a welds all day. I must say there are some damm fine welders make the shit pictured in this thread.

Fuck I wish I had some of these guys on the job I am on now for christ sakes I would be really nice to look at clean welds for a whileLeave a comment:

Leave a comment: