Plenty of money making skills exist in this thread...

Nice work fellas

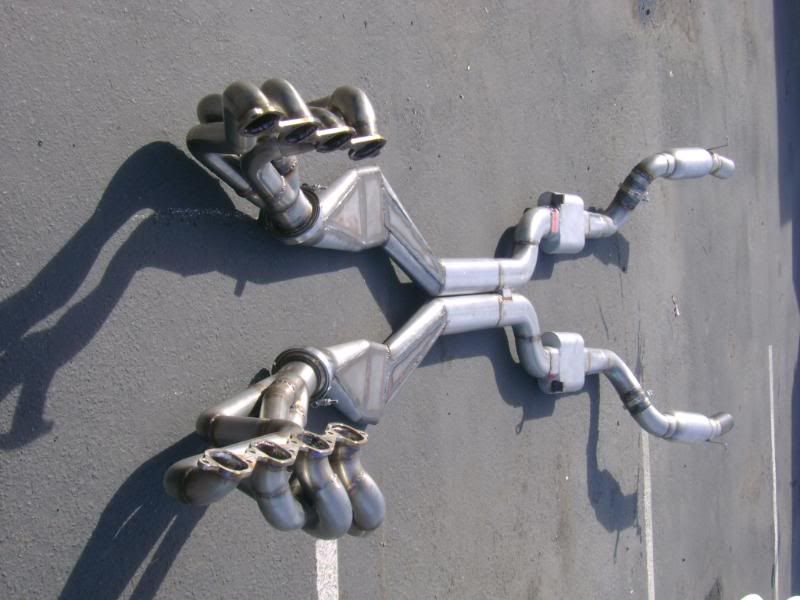

Official Fabrication & Welding Porn Photo Thread

Collapse

X

-

I can tell you why.

Because they overhaul complete powertrain, and they have to build up the turbine wheel before it gets surfaced, machined and balanced.

Heres some stuff i do at my work. Ti6al4v Titanium Impeller weld build-up inside a weld chamber.We overhaul the whole engine. The impeller get super fucked up, I have built up whole corners because impact damage has broke them off. I put weld on to bring them back into tolerance. They are then put on a tracer lath and the leading edges, contour, and diameter is cut to size. Then they go to the hand finisher aka "my bitch" and he grinds them off.Leave a comment:

-

there might be tho. if that compressor wheel is rare or very expensive it could have been saved. Maybe the blades were chipped or something idk... its alot of time and effort just for a paper weight.Leave a comment:

-

I think its more a display piece. As there would be no point in welding the tips of turbineLeave a comment:

-

-

how do you even go about balancing that. The welds are sure precise but if thats a turbo compressor wheel, they spin at 100k rpm... some serious grinding/ balancing would be in order to make that useable...Leave a comment:

-

looks like a turbo, I'm not sure the point of putting a bead on the edges, does it make them stronger? Even if it is an impeller for a water pump, it is prettyLeave a comment:

-

why are some spots on the TIG welds blue and others not?

i need to learn how to weld big time.. i have so many things i want to make for my E30 and the only missing link is a welder. providing i had the time i could easily spend countless hours working on something millimeter by millimeter all day long, i do it already with other things. kinda like once u get going ur in the zone and dont want to stop lol

my contribution from google:

thats cuz its done right!!! stainless does not like too much heat!!!!!!Leave a comment:

-

those welds make my dick hard!!!!I don't know about all of you, but more than any other type of automotive photographs, I love the close up, tight shots of amazing fabrication and machining. I think the title covers it, but post pictures that fit within the realm. Also, I say normal photo thread rules apply, but I know that by post #123 in this thread, there will be lots of banter, so be it. Lets try to keep it on topic though.

n.Leave a comment:

Leave a comment: