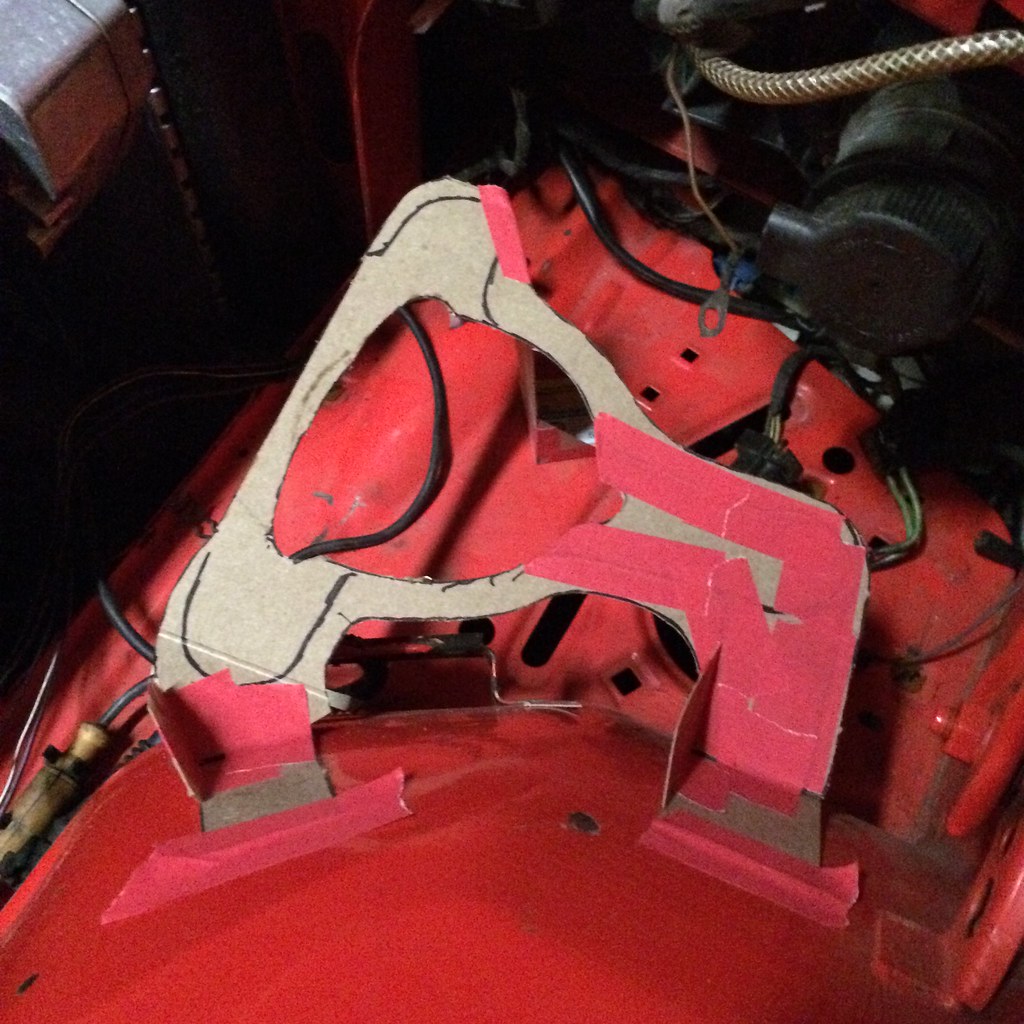

Idea

Untitled by ericandshovin, on Flickr

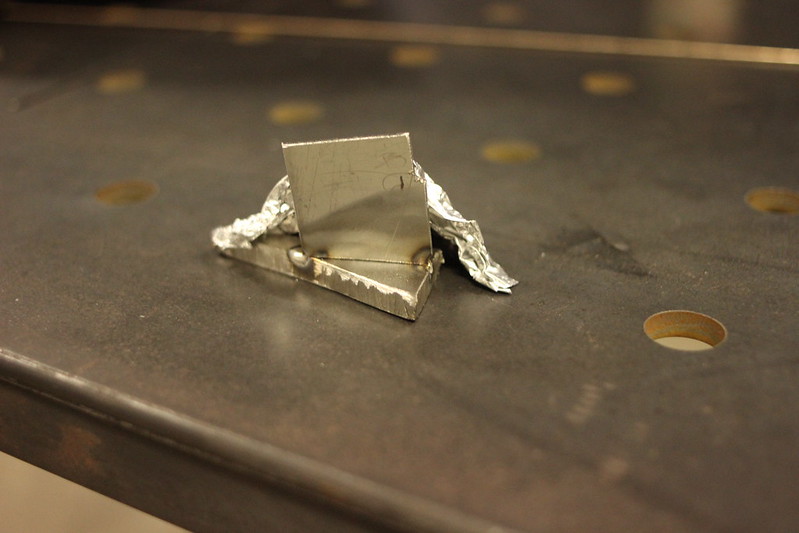

Untitled by ericandshovin, on Flickralmost finished

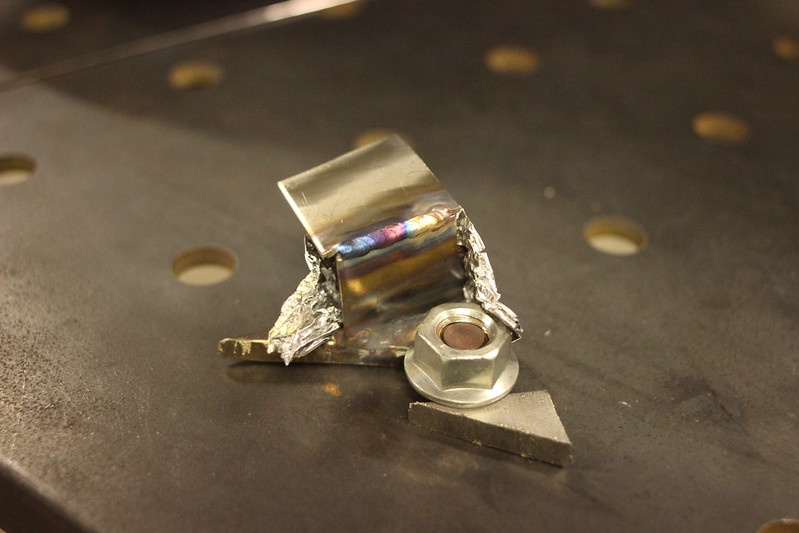

Untitled by ericandshovin, on Flickr

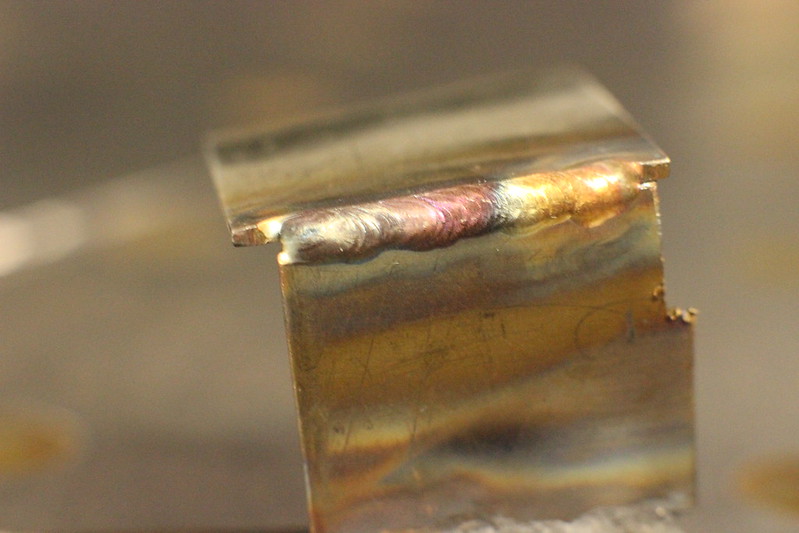

Untitled by ericandshovin, on FlickrNot going to lie here... I'm pretty disappointing with my welds. Almost enough to toss this thing in the trash and do something else for a bracket. Now, on to the excuses.

- I've always been shit with fillet on aluminum. I don't know why, I'm just terrible at them.

- 1/4" aluminum with only 175 amps on an archaic transformer box suck big donkey balls. No puddle, no puddle, no puddle, blamo blown out peanut butter goo welds.

- 3/32 tungsten at 175 amps is no fun. It was crazy to watch the ball start to rip it'self apart, a high frequency vibration right on the tip, then when it dropped into the puddle, a big puff and tons of contamination.

- an aircooled torch, even with the gas cranked up gets hot as hell, even running a tack got hot, way hot!

- real work is way harder than running beads on 6" plate in school.

Leave a comment: