Originally posted by pantelones

View Post

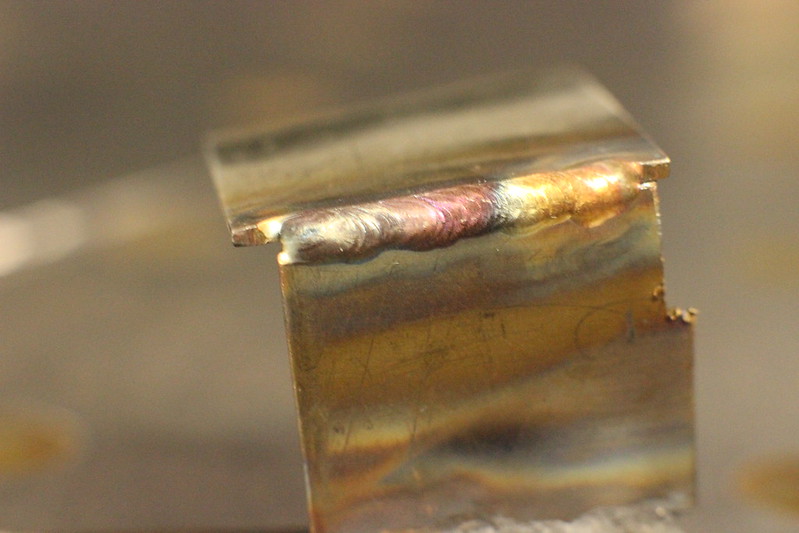

A little color never hurt no one :)

IMG_0125 by Los Pantelones!, on Flickr

IMG_0125 by Los Pantelones!, on Flickr IMG_0112 by Los Pantelones!, on Flickr

IMG_0112 by Los Pantelones!, on Flickr

IMG_0113 by Los Pantelones!, on Flickr

IMG_0113 by Los Pantelones!, on Flickr IMG_0114 by Los Pantelones!, on Flickr

IMG_0114 by Los Pantelones!, on Flickr IMG_0116 by Los Pantelones!, on Flickr

IMG_0116 by Los Pantelones!, on Flickr IMG_0121 by Los Pantelones!, on Flickr

IMG_0121 by Los Pantelones!, on Flickr IMG_0122 by Los Pantelones!, on Flickr

IMG_0122 by Los Pantelones!, on Flickr IMG_0124 by Los Pantelones!, on Flickr

IMG_0124 by Los Pantelones!, on Flickr IMG_0118 by Los Pantelones!, on Flickr

IMG_0118 by Los Pantelones!, on Flickr IMG_0119 by Los Pantelones!, on Flickr

IMG_0119 by Los Pantelones!, on Flickr

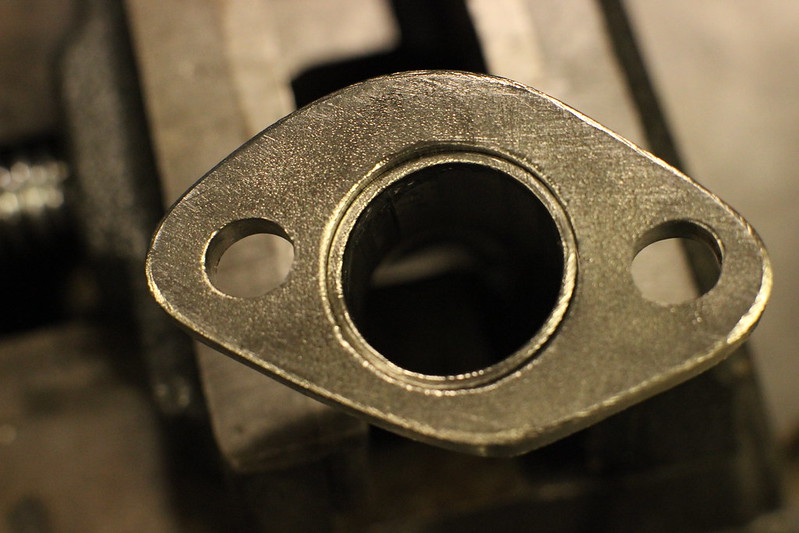

The original one was flat, and this one was only $10. I was already grabbing a tank refill so I didn't care.

The original one was flat, and this one was only $10. I was already grabbing a tank refill so I didn't care. IMG_0126 by Los Pantelones!, on Flickr

IMG_0126 by Los Pantelones!, on Flickr IMG_0128 by Los Pantelones!, on Flickr

IMG_0128 by Los Pantelones!, on Flickr IMG_0129 by Los Pantelones!, on Flickr

IMG_0129 by Los Pantelones!, on Flickr IMG_0131 by Los Pantelones!, on Flickr

IMG_0131 by Los Pantelones!, on Flickr IMG_0137 by Los Pantelones!, on Flickr

IMG_0137 by Los Pantelones!, on Flickr IMG_0138 by Los Pantelones!, on Flickr

IMG_0138 by Los Pantelones!, on Flickr IMG_0140 by Los Pantelones!, on Flickr

IMG_0140 by Los Pantelones!, on Flickr IMG_0141 by Los Pantelones!, on Flickr

IMG_0141 by Los Pantelones!, on Flickr

Comment