The Welding Thread

Collapse

X

-

Sometimes those sight tubes will spin, no such luck on that one? (dont have one here to test so don't break yours trying lol)Leave a comment:

-

Thats the one that I have. works great, only complaint is that the meter lens' are the same so the argon units are in the front on one side, and in the back on the other.I just recently had the chance to get my hands on some of the Smith equipment and wow is it amazing quality. We were almost exclusively selling Victor regulators and flowmeters and the Smith equipment blows it out of the water. Some nice positives are American Made and very competitively priced as well!

I sell the 33A-50-580 here for $177.87 + tax, it's well worth it!

Leave a comment:

-

I just recently had the chance to get my hands on some of the Smith equipment and wow is it amazing quality. We were almost exclusively selling Victor regulators and flowmeters and the Smith equipment blows it out of the water. Some nice positives are American Made and very competitively priced as well!Before I bought my dual flow meter I did the Y fitting setup. just ran it off the flow meter, make sure you get one that's NOT a ball valve style, but rather a screw style. I made a mark around 8-10 CFH. Seemed to work fine for most things. But once I started doing more pipe I just made the plunge and bought a Smith dual flow meter.

I sell the 33A-50-580 here for $177.87 + tax, it's well worth it!

Leave a comment:

-

Before I bought my dual flow meter I did the Y fitting setup. just ran it off the flow meter, make sure you get one that's NOT a ball valve style, but rather a screw style. I made a mark around 8-10 CFH. Seemed to work fine for most things. But once I started doing more pipe I just made the plunge and bought a Smith dual flow meter.Leave a comment:

-

Anyone have ideas for a cheap/diy back purge setup?

Mostly meaning some sort of Y to split before/after the regulator.

All I can think of is either running a Y to two different regulators, or Teeing off the line after the regulator and throwing a cheap airline cheater valve or regulator in the line that goes to the back purge setup. One sounds expensive and the other sounds awful.Last edited by Northern; 05-17-2015, 12:07 PM.Leave a comment:

-

I was playing around with my camera today and did some arc shots. The first one is awful as far as my welding goes, but a good arc shot.

DSC01601 by Los Pantelones!, on Flickr

DSC01601 by Los Pantelones!, on Flickr

The second one was a little better, but it's really uncomfortable trying to weld with the camera on this joint...

DSC01605 by Los Pantelones!, on Flickr

DSC01605 by Los Pantelones!, on Flickr

The beads look awful during the video - especially the butt joint, but they look pretty good for the most part. You can see exactly where there filler was balling on the filet joint!

IMG_0238 by Los Pantelones!, on Flickr

IMG_0238 by Los Pantelones!, on Flickr

Leave a comment:

-

When first starting out in welding classes, I had to take a torch welding/cutting class. We had to learn how to make an accetaline torch blow out 1/4 mild steel, make little circles, straight lines etc. At the time I only had the funky green rubber shade 5 goggle things, which was fine for the torch other than your face getting hot after a bit.

One little section of the class was plasma cutting. By this time I was getting petty good holding the torch steady with my elbows in tight, crouched over with my face probably 6 inches from the cutting surface. My teacher was oldschool and would fail you if the free-hand circle wasn't round enough... So I spent a good 4 hours on the plasma machine running cuts, making circles etc.

The next day in the shower, my first scrape of the razor on my IR burned cheeks nearly made me poop myself it hurt so bad.Leave a comment:

-

^

Wear a sleeve and you wont have those issues, with out having to throw on a full set of PPELeave a comment:

-

Thats pretty nice!Haha "sunburn". One day I was welding a heavy duty end dump together, and somehow my undershirt was pulled down enough to expose my neck down to the collar bones. Was doing a 20ft stringer overhead in a really awkward position and by the time I was done all the exposed skin was literally RAW. As in juicy, bubbly, and oozing plasma. It was the worst burn I have ever experienced.

So I started wearing these:

Keeps metal shavings and grinding dust out of your neck and ears, sparks and spatter bounce off it, and best of all, prevents your neck from getting fried.

Also, you can hold a blow torch to it for 3 minutes and nothing happens. When you're not wearing it, of course.

Usually if I'm not wearing a coat the inside of my left arm gets a bit of sunburn.Leave a comment:

-

-

When I first started welding a chemist told me about all the different cleaners/solvents and what was left behind after evaporation. Been using acetone since.Leave a comment:

-

Holy crap.....I need to check my brake cleaner. I ran out of xylene when I was building my last manifold and used it on a few pieces....Little late to the party. Just finished 13 pages good stuff going on here!

Using a Miller mutimatic for a couple of years now. I use it mainly as a MIG welder and it does a great job very smooth. Don't have a lot of time with the TIG or stick funtions but, have tried them out and again very smooth. As you probably know the TIG is DC only so no AL. If you don't need the portability and already have a nice MIG, might be hard for me to justify the cost. The huge plus of the millermatic is the portability (50 lbs. or so) and being able to stick weld when MIG just won't get it done is huge but rarely needed.

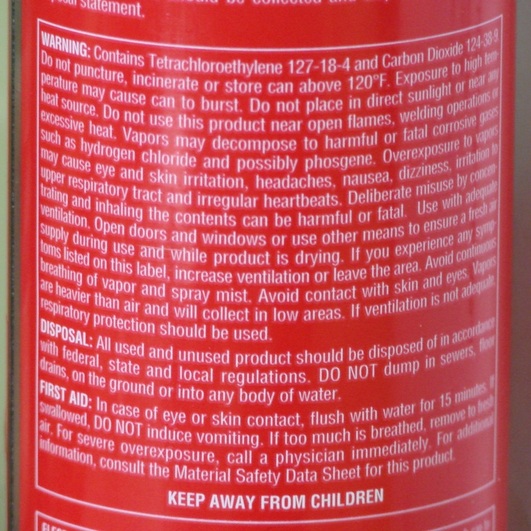

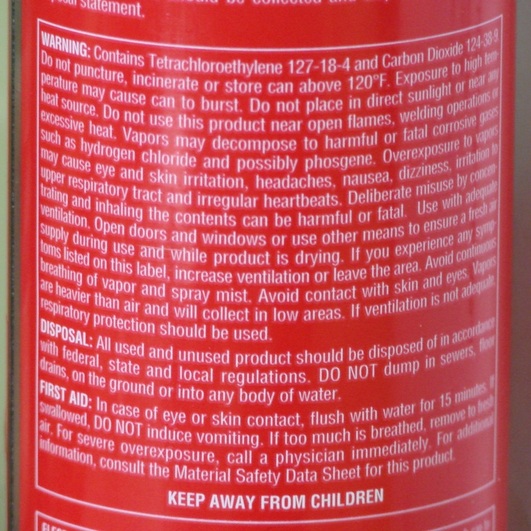

Came across this a while back:

Brew Bikes LLC 828-406-6668 Phone & Text. brewdude@brewracingframes.com BREW is a registered trademark and NO images or use without written consent.

Brew Bikes LLC 828-406-6668 Phone & Text. brewdude@brewracingframes.com BREW is a registered trademark and NO images or use without written consent.

Please take the time and read this guys story or just do not use brake cleaner or any other automotive spray. It can produce phosgene gas and just four parts per million is no good.

JHLeave a comment:

-

shit i had no idea, after doing some reading yes it looks like it's really not meant for TIG, it's just a supplementary TIG machine

also, as long as you're using non-chlorinated brake cleaner phosgene gas isn't an issueLeave a comment:

-

Little late to the party. Just finished 13 pages good stuff going on here!

Using a Miller mutimatic for a couple of years now. I use it mainly as a MIG welder and it does a great job very smooth. Don't have a lot of time with the TIG or stick funtions but, have tried them out and again very smooth. As you probably know the TIG is DC only so no AL. If you don't need the portability and already have a nice MIG, might be hard for me to justify the cost. The huge plus of the millermatic is the portability (50 lbs. or so) and being able to stick weld when MIG just won't get it done is huge but rarely needed.

Came across this a while back:

Brew Bikes LLC 828-406-6668 Phone & Text. brewdude@brewracingframes.com BREW is a registered trademark and NO images or use without written consent.

Brew Bikes LLC 828-406-6668 Phone & Text. brewdude@brewracingframes.com BREW is a registered trademark and NO images or use without written consent.

Please take the time and read this guys story or just do not use brake cleaner or any other automotive spray. It can produce phosgene gas and just four parts per million is no good.

JHLeave a comment:

Leave a comment: