The Welding Thread

Collapse

X

-

Bonus! One of the 300 cu ft ranks has 750 psi of argon left in it. The other registers nothing. Argon doesn't go bad, does it? -

I have a Smith dual flow gauge. Purge setup is pretty basic. 5-10cfm through a hose and I have a diffuser from a smaller torch threaded into the end. Just use tin foil. Have purge blocks for t3/t4 flanges and 38/44 wastegates.Leave a comment:

-

Neither of my flanges warped after welding, and I think that is also part of the reason why Burns recommends it. Fillets pull all sorts of nasty, even when you run a perfect bead, and have the part in a jig.

Looks nice :)

What do you use for a purging set up? Another tank and reg? I was going to order a dual regulator, but they are out of stock until may... :( I ordered Solar Flux B for the time being, and it should be here this week.Leave a comment:

-

Silicone bronze is a really cool filler. Not for structural purposes but for us car guys it's great. Has significantly less shrinking properties then the majority of your other fillers.Leave a comment:

-

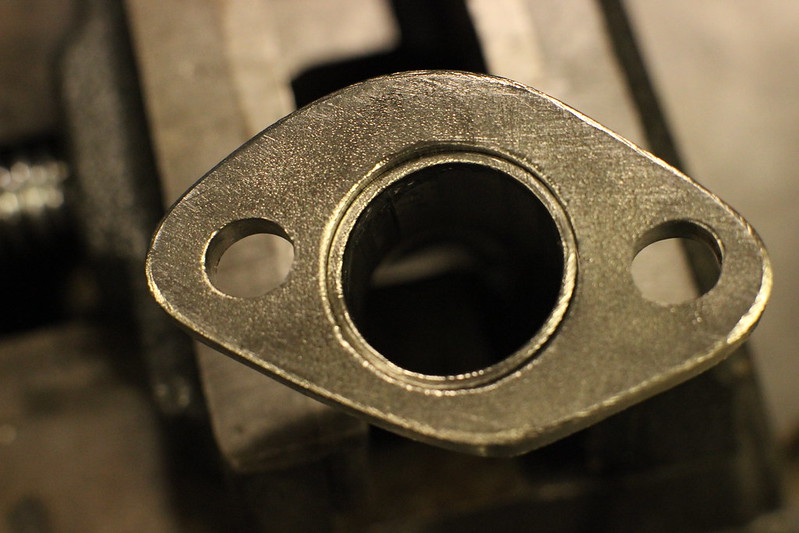

So, I wasn't just playing around with stainless for nothing... Here are a few photos of my current project.

IMG_0126 by Los Pantelones!, on Flickr

IMG_0126 by Los Pantelones!, on Flickr

IMG_0128 by Los Pantelones!, on Flickr

IMG_0128 by Los Pantelones!, on Flickr

IMG_0129 by Los Pantelones!, on Flickr

IMG_0129 by Los Pantelones!, on Flickr

IMG_0131 by Los Pantelones!, on Flickr

IMG_0131 by Los Pantelones!, on Flickr

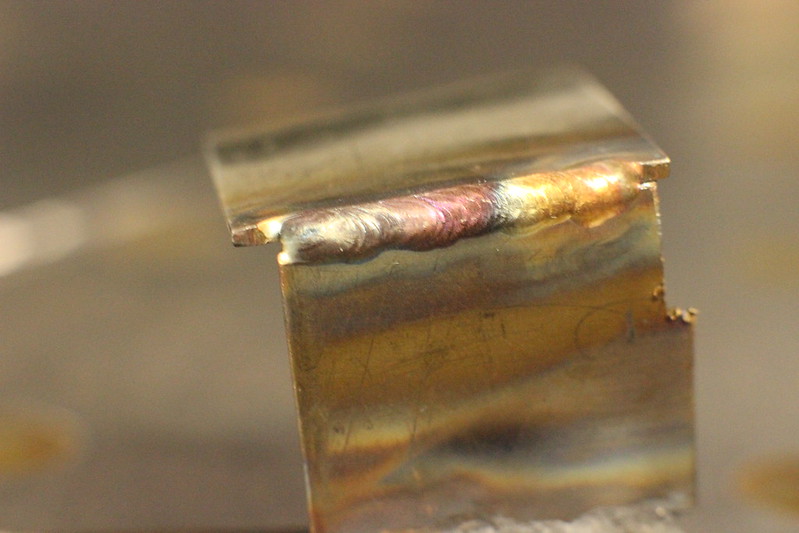

I ran less amps for the fillet on the exhaust and it turned out better. The silicon bronze rod is interesting to work with, and I am glad that I used it. I took the idea from the Burns Stainless web site, and I guess they stole it from NASCAR.

IMG_0137 by Los Pantelones!, on Flickr

IMG_0137 by Los Pantelones!, on Flickr

IMG_0138 by Los Pantelones!, on Flickr

IMG_0138 by Los Pantelones!, on Flickr

IMG_0140 by Los Pantelones!, on Flickr

IMG_0140 by Los Pantelones!, on Flickr

I really have been enjoying how much stick out you can get away with using a large gas lens ;)

IMG_0141 by Los Pantelones!, on Flickr

IMG_0141 by Los Pantelones!, on Flickr

Leave a comment:

-

You can't avoid it entirely, but it's a bad habit a lot of welders have. It's just due to running too hot/fast and not shielding properly. I thought this was pretty neat...

That is a replacement... The original one was flat, and this one was only $10. I was already grabbing a tank refill so I didn't care.

The original one was flat, and this one was only $10. I was already grabbing a tank refill so I didn't care.

And Eric, Pre-heat bud... The general rule of thumb is 1 AMP per .001" and with aluminum that could go up 10%.Leave a comment:

-

Red is 2% Thoriated, I usually tell our customers to run the Green Pure ones on the older rectifier machines and 2% Thoriated or 2% Lanthanated on the newer Inverter machines.I was of the opinion that %2 lanthinated isn't very good for the old transistor boxes. I have a pack of them, but I bought some green tips just for this project.

The machine is archaic, it has the foot pedal and a knob (numbers worn off) for current.

I was having a problem even getting the pool started. once it got a little shiney , i'd dip and it would just goo everywhere. I was using a 3/32" tungston, 1/8" rod and I think it was a 19 torch.

Thanks for the tips above, I thought I was pretty good in school, passing objectives in one or two passes, but I got a big slice of humble pie with this project!!!

Here are some of my work from school... thinner stock, inverter machine, much more comfortable.

3G aluminum:

1G lapjoint. No filler, just glueing to sheet's together.

Pipe to plate mild steel. First attempt at running a bead on round items...

Red - Yes, brushed with a SS brush, but I could still see the oxide burning up, should I brush through it?

I think if you were to preheat like IronFreak said, that may help to burn out any contaminates in the material as well as getting you a more distinguished puddle.

Those welds from school are fantastic, esp. the 3G Tig Alum, nicely done!Leave a comment:

-

I was of the opinion that %2 lanthinated isn't very good for the old transistor boxes. I have a pack of them, but I bought some green tips just for this project.

The machine is archaic, it has the foot pedal and a knob (numbers worn off) for current.

I was having a problem even getting the pool started. once it got a little shiney , i'd dip and it would just goo everywhere. I was using a 3/32" tungston, 1/8" rod and I think it was a 19 torch.

Thanks for the tips above, I thought I was pretty good in school, passing objectives in one or two passes, but I got a big slice of humble pie with this project!!!

Here are some of my work from school... thinner stock, inverter machine, much more comfortable.

3G aluminum:

1G lapjoint. No filler, just glueing to sheet's together.

Pipe to plate mild steel. First attempt at running a bead on round items...

Red - Yes, brushed with a SS brush, but I could still see the oxide burning up, should I brush through it?Leave a comment:

-

WP-26 FTW! 2% lathinated.......yeaaaah buddy.Pantalones, when you go to replace your front cover lenses, you can just get the standard 4 1/2" x 5 1/4" flat plates, the one you have on there now is for the W60 ADF filter Jackson makes. They're salty too, much more than the standard ones.

Eric, are you cleaning it up with a SS brush before welding as well? Looks like it, just making sure, a Mild Steel brush will contaminate the surface and make your welds terrible.

Are you running a WP-17 150A torch on that machine and are you running pure tungsten as well?Leave a comment:

-

Pantalones, when you go to replace your front cover lenses, you can just get the standard 4 1/2" x 5 1/4" flat plates, the one you have on there now is for the W60 ADF filter Jackson makes. They're salty too, much more than the standard ones.

Eric, are you cleaning it up with a SS brush before welding as well? Looks like it, just making sure, a Mild Steel brush will contaminate the surface and make your welds terrible.

Are you running a WP-17 150A torch on that machine and are you running pure tungsten as well?Leave a comment:

-

I have the jackson hood in a passive setup, have used it for over 9 years. I think I'm going to look at the Lincoln setups talked about earlier in this thread. Newer technology with a pretty good price point.You doing open root pipe? I've heard that industrial pipe fitting with SS is a bit tricky...

I just started playing with stainless today, and it wasn't any harder than mild steel. I was using 304L for the plate and tubing, and 308L for the 16ga sheet. Also, .045 308L, and 1/16th SiBrz filler rod.

I started with a torch only bead (fuzzy), and then a .045 filler bead (top). Don't mind the "fish-eyes" I didn't care to taper off :tsk:

IMG_0125 by Los Pantelones!, on Flickr

IMG_0125 by Los Pantelones!, on Flickr

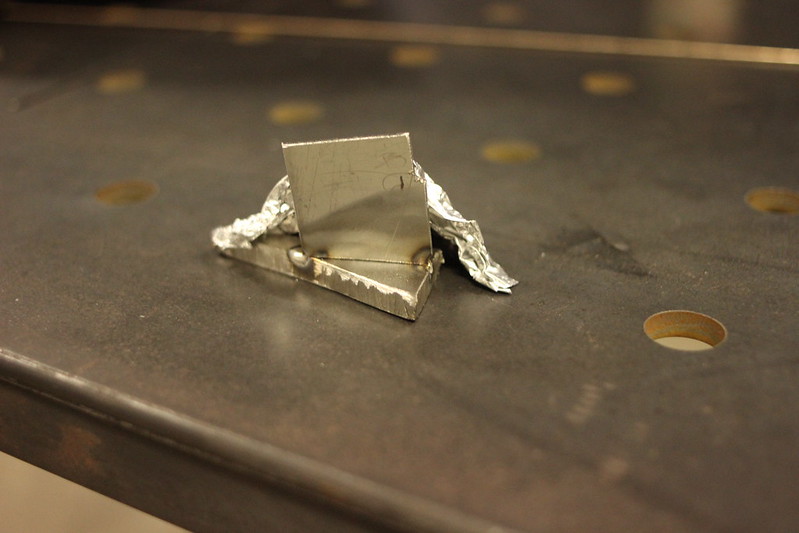

Then I did a fillet with the plate and sheet pieces, but used the silicon bronze rod. I also used a piece of aluminum foil to keep the argon trapped behind the joint.

IMG_0112 by Los Pantelones!, on Flickr

IMG_0112 by Los Pantelones!, on Flickr

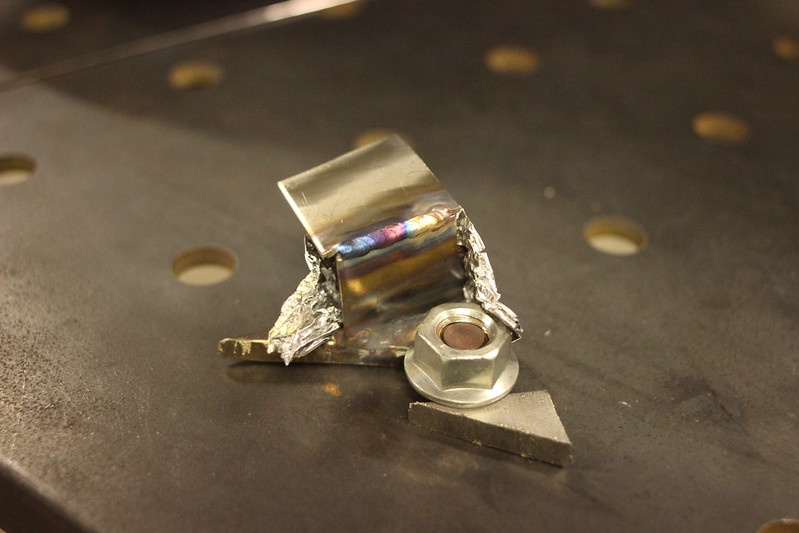

I had to stop and start... My tungsten wasn't out far enough

IMG_0113 by Los Pantelones!, on Flickr

IMG_0113 by Los Pantelones!, on Flickr

And the important part of this test...

IMG_0114 by Los Pantelones!, on Flickr

IMG_0114 by Los Pantelones!, on Flickr

I put another fillet on the back that went horribly wrong; so I redeemed myself with a decent edge joint using the 16ga sheet, and no filler. I was a bit too hot on this, so the color is a rainbow instead of straw gold.

IMG_0116 by Los Pantelones!, on Flickr

IMG_0116 by Los Pantelones!, on Flickr

IMG_0121 by Los Pantelones!, on Flickr

IMG_0121 by Los Pantelones!, on Flickr

I was happy to see my foil "dam" works... You can see the "sugar'ing" that happened when I tacked it (right side), and the puddle was not 100% shielded by argon. The technical reason for this is that the chromium draws in carbon from the air, and creates chromium-carbide; this makes not only a brittle weld, but it makes SS much, much harder to weld due to the puddle wanting to sink, and eat filler.

IMG_0122 by Los Pantelones!, on Flickr

IMG_0122 by Los Pantelones!, on Flickr

On to the tubing... (1" O.D. 16ga with no filler) This went well at the end, which is what is shown in the photo. I half ass'ed a purge set up, but is wasn't quite good enough. I only had one good bead (gold top part) after turning the amps down, and a lucky purge that worked. If you are new to stainless or Ti, you do NOT want the purples and blues, you want straw gold in the majority of your bead.

IMG_0124 by Los Pantelones!, on Flickr

IMG_0124 by Los Pantelones!, on Flickr

Oh and hoods... IronFreak if you are looking for good auto-darkening hood, I would recommend the Jackson Next-Gen or the 3M SpeedGlas hoods. I use the Jackson, and it was $280 when I bought it new 3 years ago. It has a 1/25,000 sensitivity, 4 sensors, a large viewing area, and a whole bunch of settings you can play with to suit your needs.

IMG_0118 by Los Pantelones!, on Flickr

IMG_0118 by Los Pantelones!, on Flickr

IMG_0119 by Los Pantelones!, on Flickr

IMG_0119 by Los Pantelones!, on Flickr

A little color never hurt no one :)

Leave a comment:

-

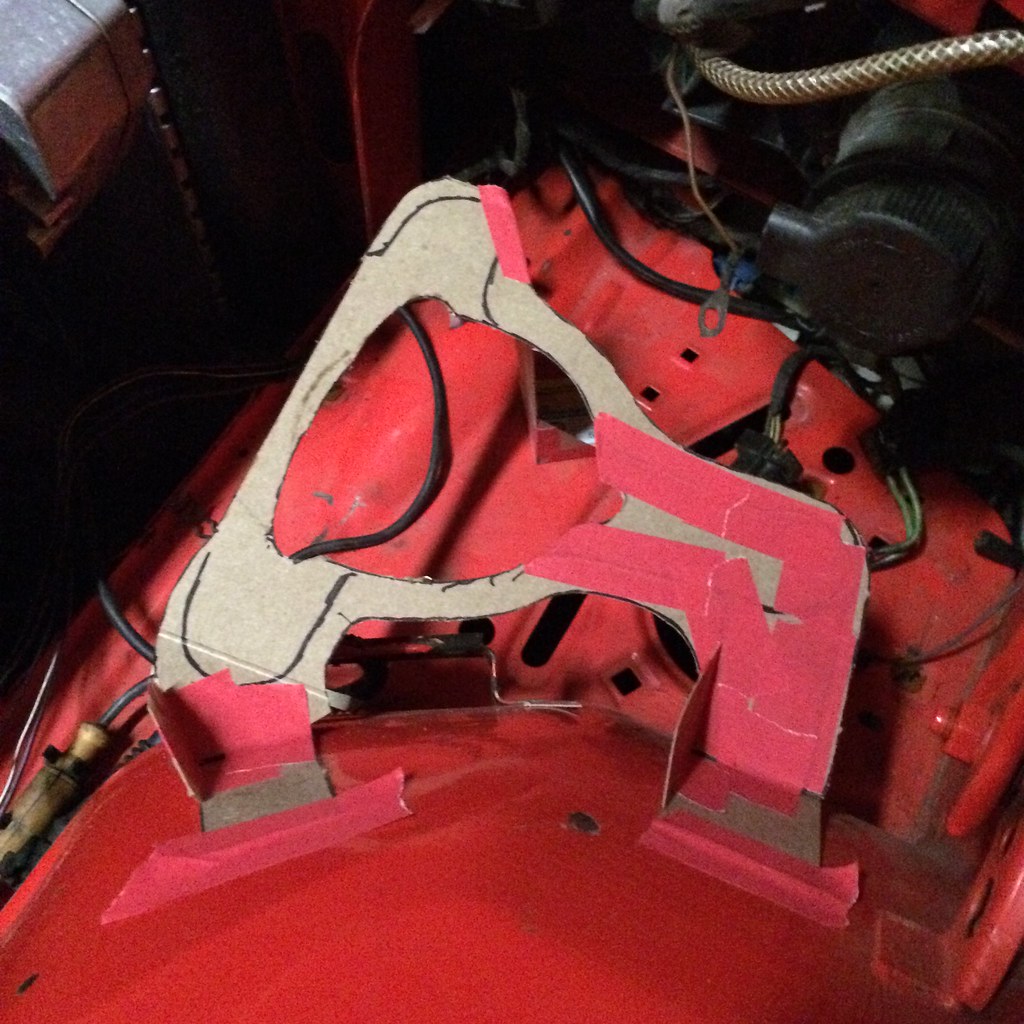

Few things to try next time on aluminum:I made a bracket.

Idea

Untitled by ericandshovin, on Flickr

Untitled by ericandshovin, on Flickr

almost finished

Untitled by ericandshovin, on Flickr

Untitled by ericandshovin, on Flickr

Not going to lie here... I'm pretty disappointing with my welds. Almost enough to toss this thing in the trash and do something else for a bracket. Now, on to the excuses.

- I've always been shit with fillet on aluminum. I don't know why, I'm just terrible at them.

- 1/4" aluminum with only 175 amps on an archaic transformer box suck big donkey balls. No puddle, no puddle, no puddle, blamo blown out peanut butter goo welds.

- 3/32 tungsten at 175 amps is no fun. It was crazy to watch the ball start to rip it'self apart, a high frequency vibration right on the tip, then when it dropped into the puddle, a big puff and tons of contamination.

- an aircooled torch, even with the gas cranked up gets hot as hell, even running a tack got hot, way hot!

- real work is way harder than running beads on 6" plate in school.

you're pushing to limits of 1/4" aluminum if all you have to play with is 175 amps, so give it a boost. have a torch handy, (butane works fine) and preheat the back side surface of your weld area. Get that thing up to about 200-250*.

Utilize the cleaning properties of AC welding, obviously do your surface prep before hand, but one you drop your hood, arc up and make a fillerless pass at a lower amperage and let the AC spot clean the welding surface, you'll visible be able to see it doing its job.

Lastly, TAKE YO DAMN TIME! Aluminum will suck the ever-living heat out of the weld, arc up, form the puddle and quick dip. On 1/4" with 175 amps, you have all damn day. If your welder doesn't have AC balance control or pulse capability.......do the foot pump! Get into a rhythm, Puddle, dip, push, pump, repeat. Gives you some pretty dimes.

What I see in those pictures can easily be cleaned up, try some of the techniques I mentioned and just go over them without using filler. You'll be surprised how well they'll clean up.

P.S. What torch are you using? I can run 175amps on mine without gloves and it's just fine, make sure it's rated for that amperage.

Here is a quick example of me using some of the stuff I talked about. This is a intake pipe for a 13B rotary. I had to cut the flange and take about 5* out of the angle. I also cut of the end where a silicone sleeve would slide over and welded on a v-band assembly. All I have is a Lincoln squarewave 175, the main flange was probably 1/2' thick. I just preheated and had no issues.

Last edited by IronFreak; 03-27-2015, 05:25 AM.

Last edited by IronFreak; 03-27-2015, 05:25 AM.Leave a comment:

Leave a comment: