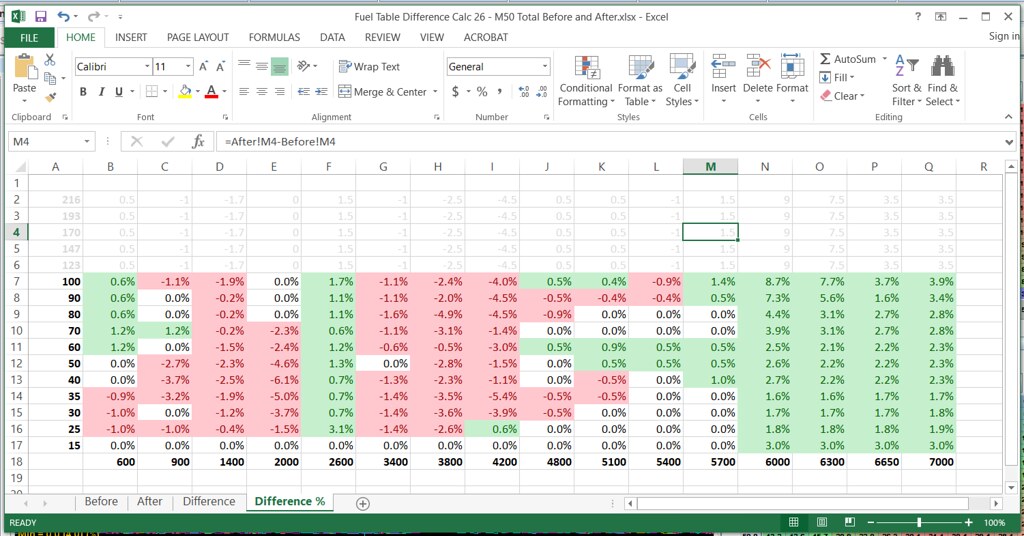

Here is my calculated Volumetric Efficiency (VE) table difference after the first logging run. Note that I had to tweak it further after this, but it gives you an idea of the general airflow change.

On a typical run where you roll on the throttle, you would see the cells in use sweep from the bottom left to the top right (100kpa row).

Note the midrange losses of 3-5% around 3800rpm, but then the gains of ~8% after 6000rpm.

This data corresponds to the "seat of the pants" and dyno results we've seen over the years with the manifold swap.

I mitigated some of the midrange loss by adjusting the VANOS crossover point and playing with timing. I bet this is how the canned tunes do it as well.

I would have loved to swap in a set of S52 cams to repeat this experiment, but I couldn't justify the cost when I knew I would be boosting down the road. I suspect the difference between the two manifolds would be even larger.

Leave a comment: