Got bit by the turbo bug.

Collapse

X

-

Replaced my bent strut tube. The replacement strut looks different then anyone i've ever cut up before.

After cutting off the dust shield i ground down the factory weld and cut the tube 2" below that.

Then i used the tool i made to perfectly weld the two pieces together straight as an arrow.

Finally busted out the ix inserts i had re-valved a year ago. I used stock i insert sleeves and shortened them 2 inches. That way i get maximum travel and no spacers. With a 6" spring it sits perfectly on the adjuster with out play when its at the maximum height. The car tucks 235/45/17s tires at the highest setting.

Leave a comment:

-

So I'm a firm believer that's 3.23 diff is the way to go. I can boost harder in 1st gear, hit 65 at 7000rpm in second, third gear is more fun and fourth gear is now pretty much what 5th used to be. That means 5th is now an overdrive gear which is what I've always wanted.Leave a comment:

-

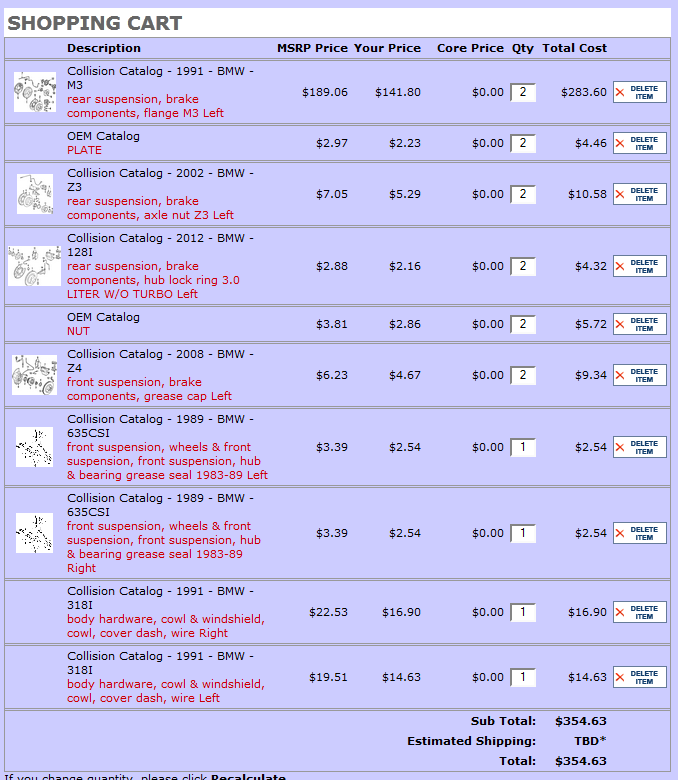

Finally got everything bolted up. At the last minute i decided not to add the IE camber/toe kit and instead splurged on a z3m complete diff. No i cruise at 2000rpm doing 65. That should put me back to 20+ mpg

I have not gotten around to getting new tires, wheels, centers, studs, etc so i just installed what i had laying around. Need to get more studs.

Leave a comment:

-

I suspect one of my trailing arms is bent since one side has always had more camber then the other even before i installed my nightmare bavauto camber/caster rear bushing kit. So i picked up a subframe and trailing arm setup and started predding it for the new 5 lug setup. It will be receiving all new IE bushing and AKG reinforcement tabs. Having a good Miller welder makes even a hack like me look like i know what i'm doing.

Leave a comment:

-

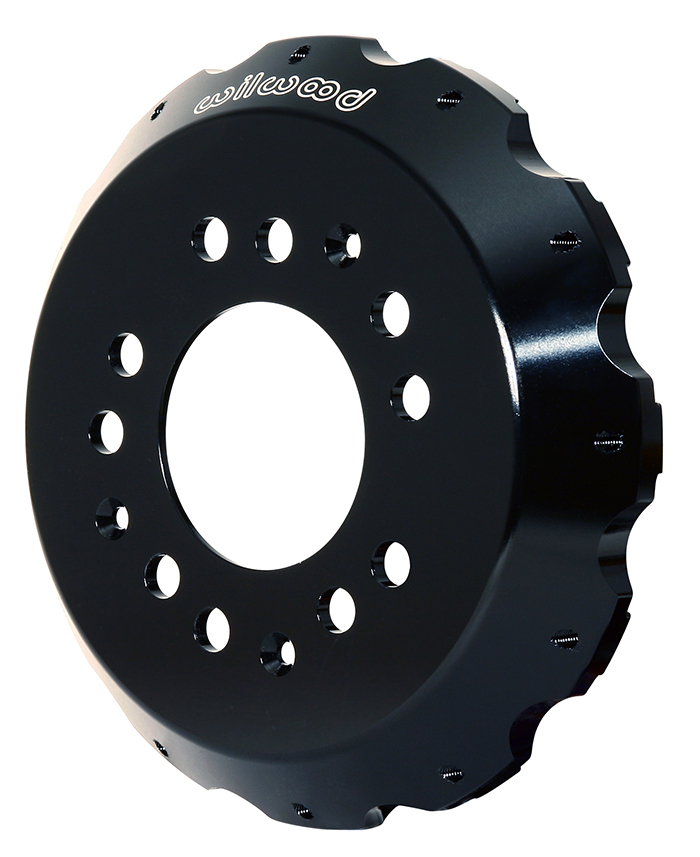

Well wilwood offers center hats with dual bolt pattern holes to reduce the number of variations they need to keep in stock and it got me thinking, why not drill and tap the hubs to also accommodate the additional set of holes. I was thinking a 5x114 bolt pattern would open up a ton of options. There are so many wheels available and cheap second hand BBS and Work wheels from Japan. Although i have decided against it as it will be cost prohibited for all the welding and machining work required for the material required to have enough threads to be safe in the rears. The back of the hubs are thickest in the are immediately surrounding the lug holes. I decided the money would be better off spent on a rebuilt SETA bottom end and cam regrind. I already have the block so its just bearings, rings, seals, and hardware. Castros will hone and o-ring the block as well as final assembly. It will give me a chance to paint the engine bay for the impending color change. This will be temporary until i can build the forged 2.9-3.1L bottom end i really want. Also the head i want will cost me another $2k to build. On top of which i want to upgrade to a ball bearing turbo. So we are talking 5-7k on my next motor.

Last edited by einstein57; 07-05-2013, 10:52 PM.

Last edited by einstein57; 07-05-2013, 10:52 PM.Leave a comment:

-

Now that's a build. That looks like a great time. I love those meaty tires.Leave a comment:

-

Well, 10 lug but i'll get in to that later. I'm going to use stock e30 M3 rear for now until I get a BBK for the rear. Front will be regular e30 strut tubes, e28 hubs with spindle adapters and a wilwood 6 piston BBK. In the end i'll pay about what people are asking for their 25 year old setups but with all new parts and better brakes.Leave a comment:

-

What exactly are you planning to use? I see a bunch of stuff that seems to overlap. I used all e30M parts and you can't beat not having to hope and guess if it will actually work. The only thing that I wasn't sure of that I now know I need to change is the master cylinder, but it's completely drivable as is.Leave a comment:

Leave a comment: