SAD SAD SAD:sad:

So i noticed some pillow smoke at start up

a day later it was running rough and she threw a check engine light

i parked her, and borrowed my girlfriends car.

spring break came around and my plan was to tear it apart.

Take off the head

Have it decked

New inner and outer valve springs

New intake guides and exhaust guides

New valve seats

Check for cracks

I took of the hood

Pulled the airbox and intake boot

Removed the radiator hoses

Removed the radiator and hit a snag

I stripped 2 of the allen screws that hold the rotor in place

I borrowed my friends dremel and cut a slot in it.

Lined up the timing marks

took the cam gear off

One trick to get this off is to break the bolt loose with the timing belt still on.

And you can hold the crank from rotating with a socket/ratchet tightening clockwise while you loosen the bolt on the cam gear.

Here the front of the motor is mostly stripped

I replaced the crank seal, intermediate shaft seal, and the housing gasket when I tore the engine apart over thanksgiving weekend. So I didn’t tear into that.

One trick to get the coolant hose on the back of the head is to remove the clamp from the passenger side.

Just a reference picture

Blue connector closer to the intake is for the ecu

Brown connector closer to the radiator is for the cluster

Here is at trick on remove the oil return tube(tube of death)

Zip tie on the entire spring not just part of it.

Label which fuel hose goes to the fuel pressure regulator or to the rail

This is also a good time to replace the fuel hose, I replaced mine right after I purchased the car.

I labeled them with blue tape and put the ends of the hoses in bottles to keep fuel from getting on everything.

1 trick to get the intake manifold off is to bend the oil dipstick to make a little bit of clearance.

Towards the front of the engine the very bottom left nut is covered by the coolant hose coming off the thermostat housing.

Make sure to get all of the nuts and washers off.

Coffee lid ftw

There are 6 nuts that attach the exhaust down pipe to the exhaust manifold

They are usually very tight and they can be difficult to get to.

I removed the motor mount heat shield and the o2 sensor heat shield

I used a 6 point deep 15mm socket 3/8 drive with a swivel a long extension and a 3 foot breaker bar.

There is a different combinations of sockets and extensions and using u joints on some and not on others.

Here is the head completely ready to come off.

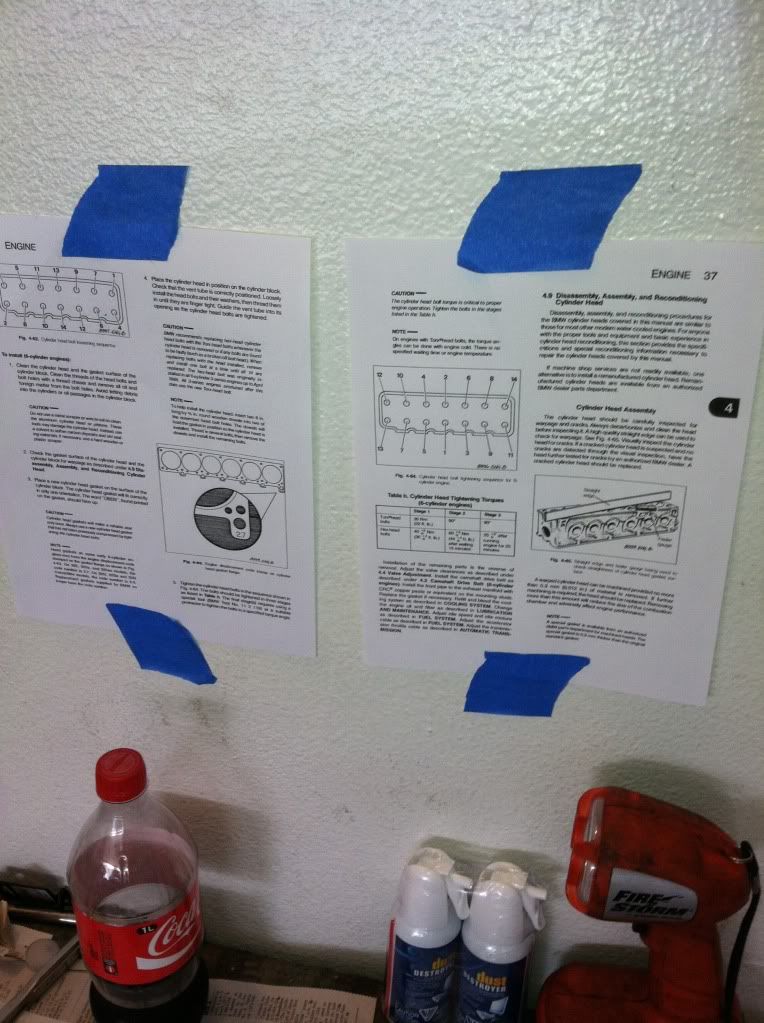

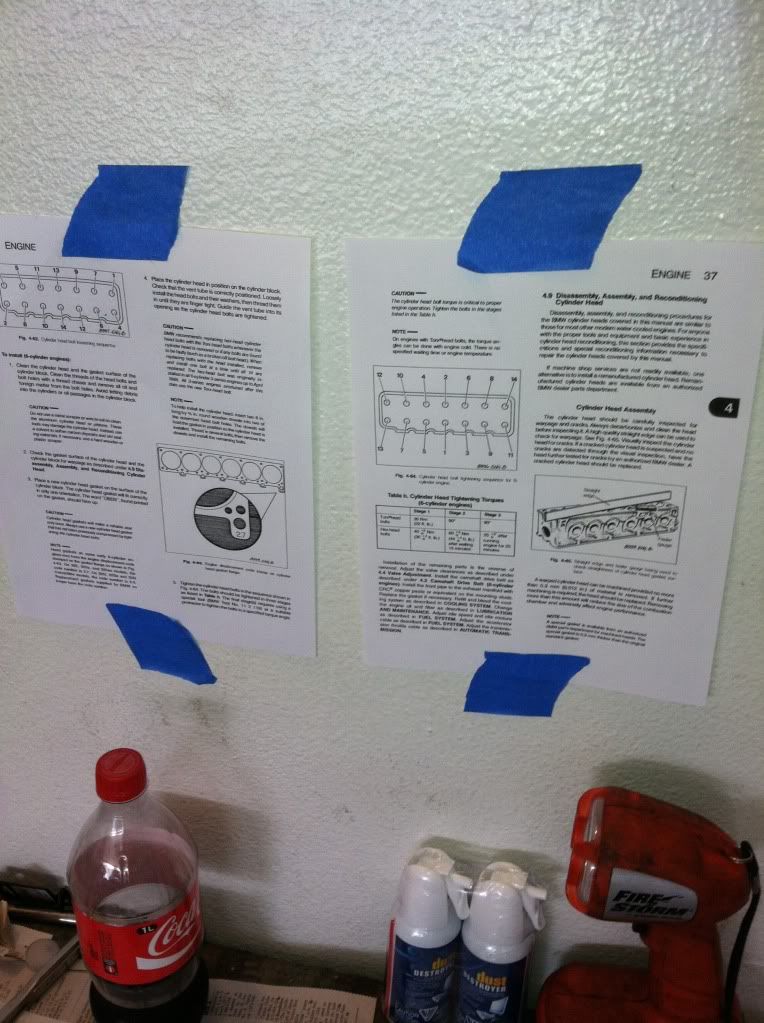

Got the Bentley PDF and printed the pages regarding the head gasket job

Gives your specs on bolt order and torque specs

My head had the old style hex head bolts sometime in middle of 1989 bmw switched to torx style head bolts.

Here we go with the cheater bar

Got the head off

Off the engine and on the bench ready for tear down

Intake manifold getting cleaned up

Cleaned up the valve cover with carb spray

Prepping the valve covers for paint

Machine shop I used for my head

Machine shop found 2 tiny cracks in the head

Since I relocated the c101 and the impulse sensor and the crank sensor I didn’t need the bracket off the intake manifold I wanted to get rid of the stud on the manifold

Double nut method got the stud off

Woo hoo

Prepping for paint

Wrinkle finish black

Head back from the machine shop

Clean

Started to clean the block

Checked the block for warpage

Checked the head for warpage

Chased the threads of the head bolts to make sure there weren’t dirty

Cleaned up the thermostat housing

Bolted up the exhaust manifolds and heat shields with new hardware

Placed the head on the block, kinda tricky to line up the studs on the exhaust manifolds to the down pipe while aligning the head to the dowel pins on the engine block

Got the head bolts torque down properly

Make sure to use the washers with the new torque bolts almost fucked that up.

Got the timing belt, water pump and tensioner installed,

Threw the valve cover on just to look at it.

I stopped here for the night.

New spark plugs getting some anti seize

I used ngk zgr5a - 5077

one tip is to adjust the valves before reinstalling the intake manifold you have a little more clearance for your 10mm box wrench.

http://realoem.com/bmw/showparts.do?...19&hg=11&fg=10

Tube of death prepped to go into the engine block

Real oem says that the engine needs 2 washer when it really only needs one.

Setup is 1 o ring

1 tube of death

1 oring

1 Spring

1 washer

Got the gaskets ready for the intake manifold

Got the intake manifold gaskets prepped with gasket cinge

Glove on the dipstick tube to protect the fresh paint from scratches

New hardware

All done

So i noticed some pillow smoke at start up

a day later it was running rough and she threw a check engine light

i parked her, and borrowed my girlfriends car.

spring break came around and my plan was to tear it apart.

Take off the head

Have it decked

New inner and outer valve springs

New intake guides and exhaust guides

New valve seats

Check for cracks

I took of the hood

Pulled the airbox and intake boot

Removed the radiator hoses

Removed the radiator and hit a snag

I stripped 2 of the allen screws that hold the rotor in place

I borrowed my friends dremel and cut a slot in it.

Lined up the timing marks

took the cam gear off

One trick to get this off is to break the bolt loose with the timing belt still on.

And you can hold the crank from rotating with a socket/ratchet tightening clockwise while you loosen the bolt on the cam gear.

Here the front of the motor is mostly stripped

I replaced the crank seal, intermediate shaft seal, and the housing gasket when I tore the engine apart over thanksgiving weekend. So I didn’t tear into that.

One trick to get the coolant hose on the back of the head is to remove the clamp from the passenger side.

Just a reference picture

Blue connector closer to the intake is for the ecu

Brown connector closer to the radiator is for the cluster

Here is at trick on remove the oil return tube(tube of death)

Zip tie on the entire spring not just part of it.

Label which fuel hose goes to the fuel pressure regulator or to the rail

This is also a good time to replace the fuel hose, I replaced mine right after I purchased the car.

I labeled them with blue tape and put the ends of the hoses in bottles to keep fuel from getting on everything.

1 trick to get the intake manifold off is to bend the oil dipstick to make a little bit of clearance.

Towards the front of the engine the very bottom left nut is covered by the coolant hose coming off the thermostat housing.

Make sure to get all of the nuts and washers off.

Coffee lid ftw

There are 6 nuts that attach the exhaust down pipe to the exhaust manifold

They are usually very tight and they can be difficult to get to.

I removed the motor mount heat shield and the o2 sensor heat shield

I used a 6 point deep 15mm socket 3/8 drive with a swivel a long extension and a 3 foot breaker bar.

There is a different combinations of sockets and extensions and using u joints on some and not on others.

Here is the head completely ready to come off.

Got the Bentley PDF and printed the pages regarding the head gasket job

Gives your specs on bolt order and torque specs

My head had the old style hex head bolts sometime in middle of 1989 bmw switched to torx style head bolts.

Here we go with the cheater bar

Got the head off

Off the engine and on the bench ready for tear down

Intake manifold getting cleaned up

Cleaned up the valve cover with carb spray

Prepping the valve covers for paint

Machine shop I used for my head

Machine shop found 2 tiny cracks in the head

Since I relocated the c101 and the impulse sensor and the crank sensor I didn’t need the bracket off the intake manifold I wanted to get rid of the stud on the manifold

Double nut method got the stud off

Woo hoo

Prepping for paint

Wrinkle finish black

Head back from the machine shop

Clean

Started to clean the block

Checked the block for warpage

Checked the head for warpage

Chased the threads of the head bolts to make sure there weren’t dirty

Cleaned up the thermostat housing

Bolted up the exhaust manifolds and heat shields with new hardware

Placed the head on the block, kinda tricky to line up the studs on the exhaust manifolds to the down pipe while aligning the head to the dowel pins on the engine block

Got the head bolts torque down properly

Make sure to use the washers with the new torque bolts almost fucked that up.

Got the timing belt, water pump and tensioner installed,

Threw the valve cover on just to look at it.

I stopped here for the night.

New spark plugs getting some anti seize

I used ngk zgr5a - 5077

one tip is to adjust the valves before reinstalling the intake manifold you have a little more clearance for your 10mm box wrench.

http://realoem.com/bmw/showparts.do?...19&hg=11&fg=10

Tube of death prepped to go into the engine block

Real oem says that the engine needs 2 washer when it really only needs one.

Setup is 1 o ring

1 tube of death

1 oring

1 Spring

1 washer

Got the gaskets ready for the intake manifold

Got the intake manifold gaskets prepped with gasket cinge

Glove on the dipstick tube to protect the fresh paint from scratches

New hardware

All done

Comment