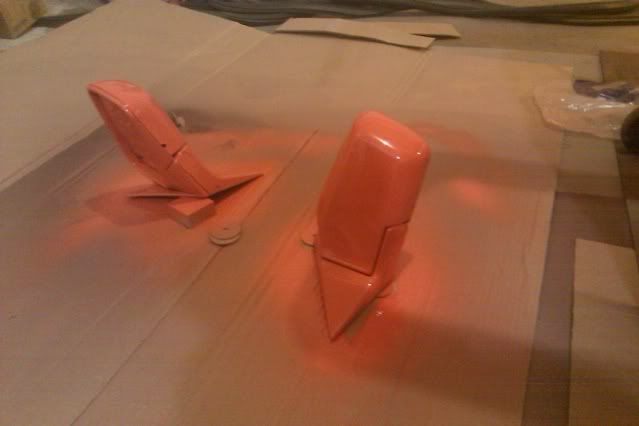

I decided to paint the accent pieces that were removable from the car, the mirrors, front lip, and rear lip. I sanded, cleaned, and did all of the normal prep for the parts. The epoxy primer went on really nice, and after a little flash time I sprayed the orange urethane paint.

Really happy with how things look so far, I'll let the paint cure(hopefully) and go from there.

Leave a comment: