Great project Jake, top notch work in this thread!

I also spent most of my morning drooling and dreaming.

And I have the same birthday! :)

I was wondering if you could PM or post more information on your TIG welder!

Thanks

Dustin

E36 M3 - LS3/TR6060 Swap

Collapse

X

-

-

Looking great! I should ship my S10 over to you for the 5.3 swap. Ha!Leave a comment:

-

I went to school for welding, my dad was in the industry for years....It an art and therapeutic. I haven't tried any aluminum with mine yet, with the 175 I think I'm fairly limited to thinner pieces. I have done quite a bit of mild and stainless. I did a stainless oil tank for my uncles cafe racer, didn't back purge but I had decent overlap on all the parts, no porosity and its still holding oil!Leave a comment:

-

thanks! Welding thin stainless is not a simple task. I have only had the tig about 8 months. Getting better every time I use it tho. I bought it to mostly do stainless. I've done a little aluminum but mostly just practicing.Leave a comment:

-

The welds look good! I have a Lincoln Sqaurewave 175. I'll be pulling it out once I get the new shop setup. Keep up the good work!!Leave a comment:

-

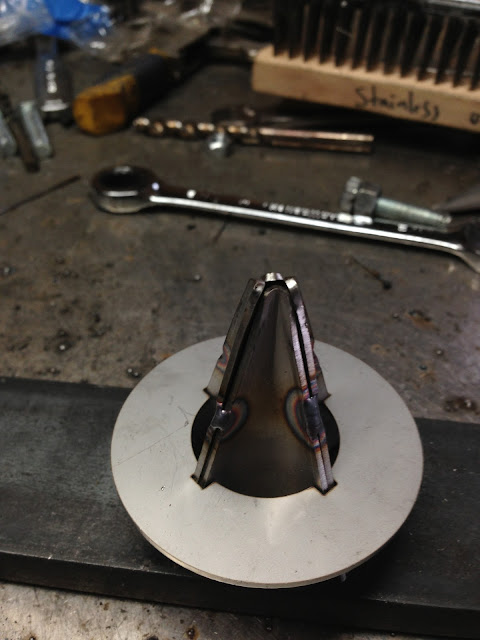

The Merge Bullet on the header

Collector isn't welded yet but just to get the idea..

Welding for hours on end gets a little boring so I changed it up....also bending over the bench gives you a sore neck. I need something to raise the work piece higher when welding.

Anyway...first a sound deadening material went on the firewall.

Then a heat shield material. I have done this same setup on 2 cars before this and it has worked great.

Bad picture but heater hoses going to their new homes. Brake lines back in place.

Still unsure if I will come up through the battery tray for the heater hoses or not but this does look to be the cleanest route.

Leave a comment:

-

Just spent a good portion of my morning reading 14 pages. Stunning work! Keep it up!Leave a comment:

-

It's a no name AC/DC 200amp unit. My buddy has one and was really happy with it so I gave it a go. I would recommend them to others for sure. Very happy with itLeave a comment:

-

More welding today...all the runners are done and putting the headers back together. Inside the collector gets a merge bullet.

They start with 4 little peices

Go into this little jig

Tacked

Welded

cleaned up

I forgot to snap a pic of the bullet on the header...inside for lunch at the moment. I'll get some more in a bit.

Runner welded to the flange. They will get fully welded inside the flange for the most part.

That little drop must be from the end of the filler...that will get knocked off there.

Leave a comment:

-

Better picture of the back purge...argon comes in the left and then there is a stopper in the right side of the tube.

I use a small torch but a Large Gas lens with the biggest cup I can get so that the weld has a nice blanked of argon.

Drivers side runners...all but one are done. I ran out of Argon....already have a filled tank but no more time today.

Leave a comment:

-

Today is tig welding day....welding headers and waiting on UPS.

Sorry for the bad picture...not sure what happened here. Anyway the headers are stainless so they need to be back purged with argon.

Here is my back purge setup for a single tube.

Passenger side tubes all welded

A bead shot...might be a tad hot here.

On to the drivers side. Doesn't look like much but it's slow moving work. FUn stuff thoLeave a comment:

-

Put the rear calipers back together after coat.

Thought I had more sound deadening....nope. Have to order some more. Then it is get covered with DEI heat shield.

The plan was to fully weld the headers today but I couldn't find the big cups for my tig welder the other day....I was hoping they would be here today, nope. Maybe tomorrow.Leave a comment:

Leave a comment: