My turbo 24v alpine coupe

Collapse

X

-

Your off to a good start. I would recommend spraying all of the headgasket layers and mating surfaces with copper spray. -

Finally have some progress AND pictures. Went into work and didn't have any cars to work on, so I worked on this project.

First I painted the block and cleared it.

Then I chased all the threads on the block including the the ones for the headstuds. Then i cleaned all the pistons in the parts washer and then got all the carbon off the tops. They were pretty dirty.

Then I honed the cylinders and they came out great. I checked the gap on the piston rings and they were all good. I installed those. The pistons are ready to go in. I was able to clean the block really well before I left and wrap it so it is all ready to build next time I have a chance to work on it. I have all the old bolts ready to plastigage it, and all new rod and main bearing bolts for assembly

I'm very excited to put this thing together. I need to order stuff, but I have been focused on finishing up the semester and not had work. Gonna get the rest of the things I need for the engine, and the fuel pump and a few other things. Also going to start taking my harness apart to wire it into the P8 pro and switching the C101 to my new harness.

Goal is starting it up mid january. Were gonna break in the engine and clutch on the dyno =]Leave a comment:

-

I wish! That tool would make things a hell of a lot easier. I've read a a few DIYs, but I haven't seen that method of loosening the bolts mentioned before. I think I like your approach best.Leave a comment:

-

yea sure. the first time i did it i had the supervision of a BMW tech. but now ive done it like 5 times. i do it at TDC, theres always going to be one pair of valves open on both sides. At TDC its usually cylinder 3 or 4. Once all the timing chain stuff is off, start from the middle. then, go diagonal to the ends. ONLY DO A QUARTER TURN AT A TIME. from the ends, go back to the middle diagonally and do the ones you havent done. work your way to the other side. Keep doing this slowly, quarter turns only. some will become finger loose, but dont turn them more then a quarter turn. Once it starts to lift, pay attention to how much gap there is between the cap and the cam tray, try to keep them about equal. The goal is to just gradually lift the whole cam. Be careful about dropping the nuts and taking the nuts off at the last turn when there is tension on them, sometimes they will pop off. Installation is the reverse of removal. i believe the torque spec is 19ft lbs. Make sure you clean all mating surfaces. The caps are labeled too.

I ALWAYS try to keep track of the lifters and cam trays. I have 24 bags with labeled with E or I 1-12. In german, intake starts with an E and exhaust starts with an A. This makes it a little confusing because you would think E is exhaust. Especially when theres some mileage on the cams it helps to use the same lifters and trays.

Another trick i learned, if the engine is on the stand, you can put all the lifters in the tray, and tilt the motor so that when you flip the tray over, all the lifters wont fall out, otherwise, its a pain to get all the lifters lined up, as they can only be inserted through the bottom of the tray.

OR get on the waiting list for the 1600 dollar tool from germany that holds the cam down.

Leave a comment:

-

Can you explain the process you used? I have to remove the cams from my s52 this weekend, and I am super paranoid about breaking them.Leave a comment:

-

still an idiot and forgetting to take pictures.

Motor is back from the machine shop. Everything looks good. Got it hot tanked but not anything else because im using the same pistons. Spent a little bit of time on friday getting it on the engine stand and taped off for paint.

I want the engine bay to have a functional theme to it. I was thinking about doing a purple and black theme but I just want to keep it simple. Low gloss black. Im going to delete unused brackets and wires and paint it. Nothing fancy. Function>form with this build. Im planning on doing black intercooler piping, black couplers. Everything will be black except the stainless steel lines and the polished turbo.

No work will get done until next week. I have my first final exam tomorrow and a presentation in 2 different classes. 2 finals next week and then we will start to see some REAL progress here. I love my work. Boss said im free to come in and work on my car whenever he doesnt have any work for me. I have until Jan 27th until I go back to school, hoping to be done with the motor/turbo build by then.Leave a comment:

-

im horrible at taking pictures. I did the e36 rack swap this week. Was pretty easy because it is an airbag car. Just have to clearance the firewall a little for the steering shaft and ive had the spacers and rack sitting forever. I took the s52 cams out of the old motor and put m52 cams in to get it ready for sale. Took me a while to get the cams out without cracking them.

PARTS ON PARTS

my KAmotors fender flares arrived and are in there. I also have 2 boxes of stuff at work, the car filled with parts, and the motor at the machine shop.

Im also thinking about doing the car in stages

1- motor swap, paint bay, turbo, bbk, fix coilovers

2- interior and safety (remove dynamat and fix roll bar)

3- paint and wheels

thinking of upconverting to 17x 9 and 10 for my rs, and maybe a solid color scheme so i dont have to worry about polishing the lips. I want to rebuild them anyways. Thats down the road.Leave a comment:

-

Main hoop is all one bar.

Sent from my SAMSUNG-SGH-I337 using TapatalkLeave a comment:

-

You sectioned and welded your main hoop? That's a pretty big no no from what I do know about roll cages. May not pass tech...Leave a comment:

-

got my new motor to the machine shop today. when i called a few months ago they told me it would take 3 weeks, now itll be done late this week/ early next week. SWEET.

i got my brake line splitter to delete abs, wideband, intercooler, and fender flares should be here friday.

I also made a spreadsheet of all the connections at the ecu for the m50 harness I have, now i just gotta match it up to the DTA connections. the dta has everything in order of firing order which makes it a little more confusing. I also found that I have an extra engine wiring harness, it really good shape, except the car side is missing, however, i can cut the c101 off my other harness a just splice everything together.

Hopefully ill have less wiring and more pictures for my next update.Leave a comment:

-

if all works out well ill be trading my vaders for some fresh corbeau fx1's. I think im gonna put them on e30 rails and get the massive adapters. hopefully that works.

I am having trouble thinking of a price to sell my old engine at. It ran REALLY well, minus the vanos rattle which i will investigate. Its a rare motor, its healthy...compression numbers were all within spec. The more I can sell it for the more i can buy.

right now i have coming:

intercooler (right off a 24v turbo e30)

rest of my rx7 brake kit (fittings and rotors)

fender flares, should ship monday

and i need all my fueling stuff, plx wideband, intercooler pipes, stuff to wire the new ECU, exhaust stuff. budget still shows i am about $2k away from having all the parts and the machine shop bill paid.Leave a comment:

-

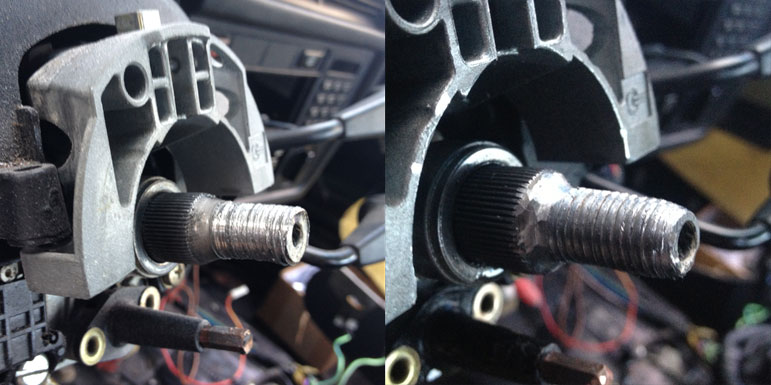

Yea. I was think of doing that. I only replaced the shaft, not the whole column. After I figured out how to take it out putting the new one in wasnt very hard.

Made some good progress today. Pulled my old motor. Im glad im redoing the harness because it and all the wiring is sketchy. The clutch and flywheel are still in good shape so they are sellable. Im going to have to redo the coilovers. The play in them destroyed the camber plates.

Anyways heres today...

Pulling it from the bottom was so much easier. Had some problems with the steering shaft and took a coolant shower :/ had the motor out in 2.5 hours by myself.

Sent from my SAMSUNG-SGH-I337 using TapatalkLeave a comment:

-

nice build, but bro you don't have to replace the column - you just grind down the shaft until it's smooth and has no threads and then died a new thread

Leave a comment:

-

Rebuild parts came today. Unfortunatley didnt have enough time to take out my old m52 at work today. Maybe next week.

Sent from my SAMSUNG-SGH-I337 using TapatalkLeave a comment:

Leave a comment: