the FPR is overrun though. holds like 55psi at idle with the adjustment screw all the way out. Hoping I can find a kink in the line but if not I may just run a -6 line all the way back to the tank. I feel like I am chasing my tail on dialing in the fuel in the tune until this is fixed. Fuel pressure is most likely all over the place because I cant dial it in at idle.

Went for a 15 minute back road drive. Longest she has been out and driving in like 4 years. It was a blast. The throttle adjustment stop wasnt tight and the nut fell off, so the screw slowly made its way out. By the time I got back to the shop it was holding the throttle open 15%.

idles smooth as butter. I had to adjust the throttle so it was alot more closed at idle. I had 0% DC on the ICV and it was idling around -5 degrees of timing. Once I closed it more, I was at 5 degrees and 40% DC on the ICV, which I hear is normal.

After I originally went driving in it i noticed that my tail lights, wipers, and blower motor wouldnt turn on. I went into the fuse box to find that those fuses were fine, but with a test probe, they would only get power if I pushed on them a certain way. No wonder why the P.O. had wires running around the fuse box and wire wrapped around a few of the fuses. I bought some electronics cleaner and cleaned all the fuses and the fuse box and then bent some of the terminals in the fuse box so that they had a tighter grip on the fuses. Everything works now.

Also, the oil pain wasnt stripped. The damn mishimoto magnetic oil drain bolt snapped. I had like 15 ft-lbs on it. They drill out the bolt for the magnet, but the hole/magnet are too big and theres no meat left on the aluminum bolt where the threads are. Put a crush washer on a normal bolt and no more leak at the oil pan.

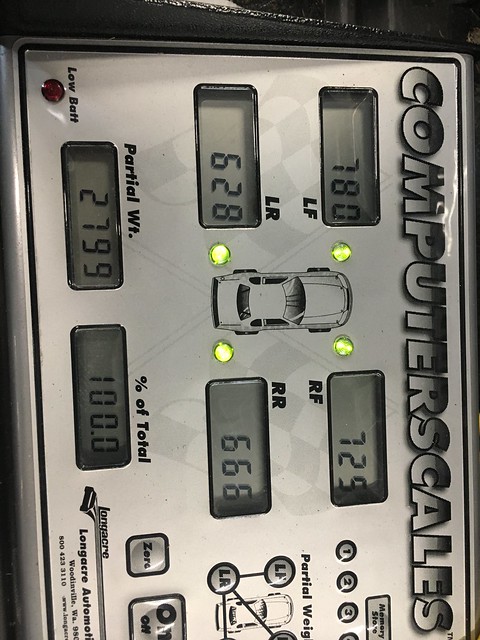

IMG_0478 by mitchlevy7, on Flickr

IMG_0478 by mitchlevy7, on FlickrInstead of fixing the adjuster on my drivers side low beam, I just stole it from the passenger side high beam and took it out to give the intake air.

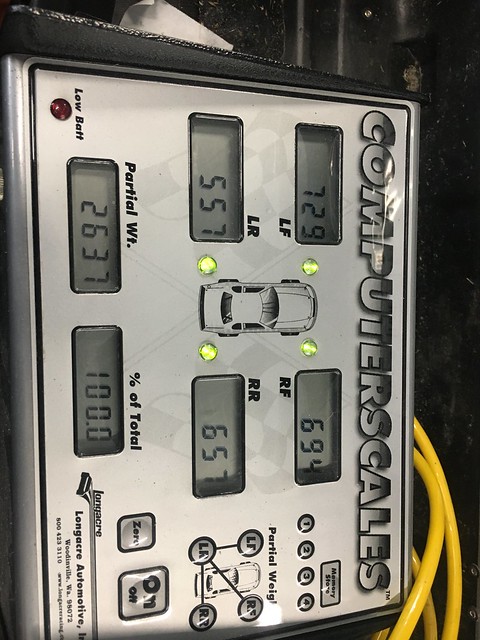

IMG_0495 by mitchlevy7, on Flickr

IMG_0495 by mitchlevy7, on Flickr Whats left:

-Figure out FPR overrun issue

-Bleed the brakes a little more

-tune it

-paint some of the trim (the kidneys look terrible)

-Take it down the south carolina

) and new VC gasket. Was unaware the gasket was different too.

) and new VC gasket. Was unaware the gasket was different too.

Leave a comment: