Blunttech / Classic Daily S85 V10 E30 M3 Swap

Collapse

X

-

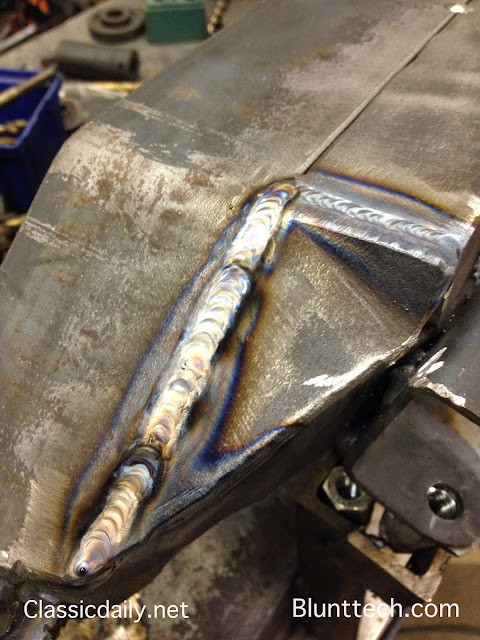

thanks...I will say I am far from great on the tig but getting better and better with more and more practice. And they are plenty strong.

Leave a comment:

-

Great penetration on the weld. I love a good looking weld even if it's not a challenging one. Awesome progress on the build! I can't wait to see this monster done.Leave a comment:

-

This update is from a few weeks ago but just finally getting around to uploading all the pics and posting.

Welding the new subframe up.

Starting on mounts

drivers side

These will be fully boxed and also a new set of plates will be drawn and then water jetted. These are the mock ups.

Subframe with mounts welded on

And with both mounts connected. All this will be powder coated

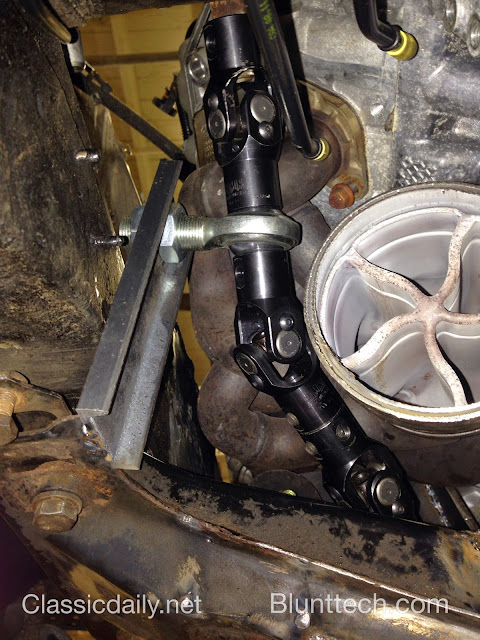

Steering clearance

Adding another joint

And a locator

This is JUST a MOCK up. We needed to have the car movable to take to a show so this locator mount was just tacked on so the car can steer. There will be a stronger more elegant solution once the engine comes back out.

Rebuilt rear axles

A quick shot from the front.

The coilovers are turned all the way down here and there is about 3-3.5" here. Yes it is close but the air boxes are about a 1/4" from the hood.

Here it is at the vintage in NC a couple weeks ago.

Also it is looking VERY good that we will be using the stock DME. nando has been working on cracking it and it's looking like it's gonna happen.

Leave a comment:

-

Oh nice, yeah those mounts should keep her in place! Do you have enough room for the steering lines on the rack, since the e30 rack has the ports facing the engine? Parker makes 90* metric to AN fittings that could save some space if needed.

Might want to throw a bit of Loctite on the set screws that hold the u-joint bearing in place on those flaming river joints, I had one back out on me. Not fun to get to with the car fully assembled haha.

Yeah there is actually a good amount of room for lines. By good amount I mean enough room for the lines. They will need to be something custom I am sure but I made sure there was enough room.

Good tip on the lock tight on the flaming river set screws. The one up by the firewall will be VERY hard to get to.Leave a comment:

-

thanks! Yes it is a bummer that we couldn't use the z3 rack. The difference of the pinion angle is just slightly different from the e30 to e36 racks but just enough that it caused issues for us here.

The s85 is a really tall engine. When I make the mounts the engine will go up just a tad. But the main reason is to give more ground clearance. As the subframe is already coming down lower than stock.

Like this

So there won't be much movement.

Oh nice, yeah those mounts should keep her in place! Do you have enough room for the steering lines on the rack, since the e30 rack has the ports facing the engine? Parker makes 90* metric to AN fittings that could save some space if needed.

Might want to throw a bit of Loctite on the set screws that hold the u-joint bearing in place on those flaming river joints, I had one back out on me. Not fun to get to with the car fully assembled haha.Leave a comment:

-

WOW....I need a ride on this once its done... Not on you Steve settle down...on the car...Leave a comment:

-

thanks! Yes it is a bummer that we couldn't use the z3 rack. The difference of the pinion angle is just slightly different from the e30 to e36 racks but just enough that it caused issues for us here.Amazing work on that subframe! Sucks that the header prevented the use of the Z3 rack. I've been looking for a fast ratio rack with a pinion angle close to the stock e30 rack, for header clearance. Not sure if that exists.

Why is the plate under the pan so close? I'm not familiar with the depth of the s85 pan, so I assume it's for maximum ground clearance. I'd just be worried about contact there, depending on the engine mounts used. My m60 settled probably 1/4" within a few thousand miles on stock m60 mounts, which allowed contact between the rack and oil pan. Didn't take long to do damage after that...

The s85 is a really tall engine. When I make the mounts the engine will go up just a tad. But the main reason is to give more ground clearance. As the subframe is already coming down lower than stock.

Like this

So there won't be much movement.Leave a comment:

-

Amazing work on that subframe! Sucks that the header prevented the use of the Z3 rack. I've been looking for a fast ratio rack with a pinion angle close to the stock e30 rack, for header clearance. Not sure if that exists.

Why is the plate under the pan so close? I'm not familiar with the depth of the s85 pan, so I assume it's for maximum ground clearance. I'd just be worried about contact there, depending on the engine mounts used. My m60 settled probably 1/4" within a few thousand miles on stock m60 mounts, which allowed contact between the rack and oil pan. Didn't take long to do damage after that...Leave a comment:

-

didn't realize you guys were building this in Michigan until I saw the post over the weekend on the Michigan bmw facebook page!

what part of michigan? I'd love to see this beast in person sometime.Leave a comment:

-

-

Also come see it at the blunttech booth at vintage in NC this coming weekend...Leave a comment:

-

Well the subframe from before was a bust.... The z3 steering rack was wanting to be in the same spot as the header. So we start again.

The engine about in it's final location

This is the e30 m3 rack rotated slightly down to clear the header.

Rack in it's new home in the subframe jig.

Bending a piece to connect the dots

Trimmed down and tacked together

Testing and ears for rack

Boxing it in

You can see a piece of bent plate going under the pan here. This piece was fun to make.

Tacked together

Clearance to the pan...around 1/8-1/4"

Out of the car

I really like how this part came out. Some little open holes still.

Before (opposite side of after pic)

After

Still more cleanup needed.

Entire thing before welding...

Leave a comment:

Leave a comment: