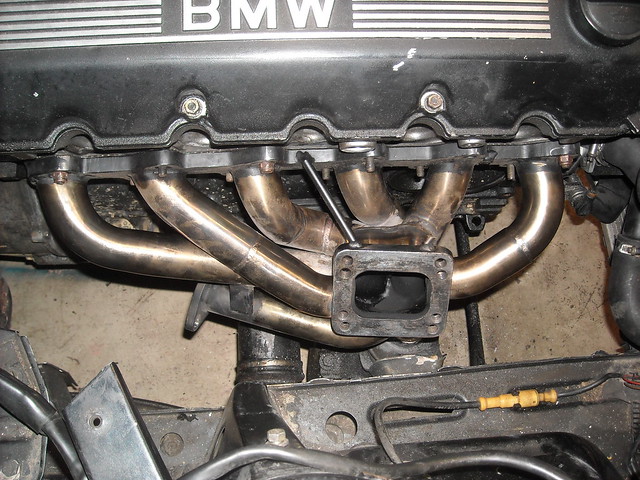

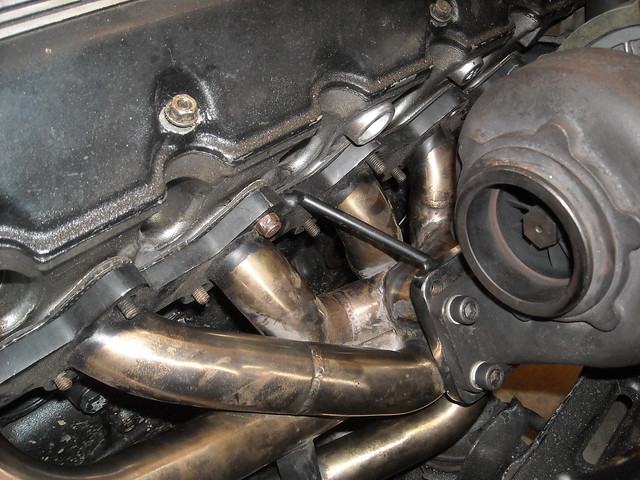

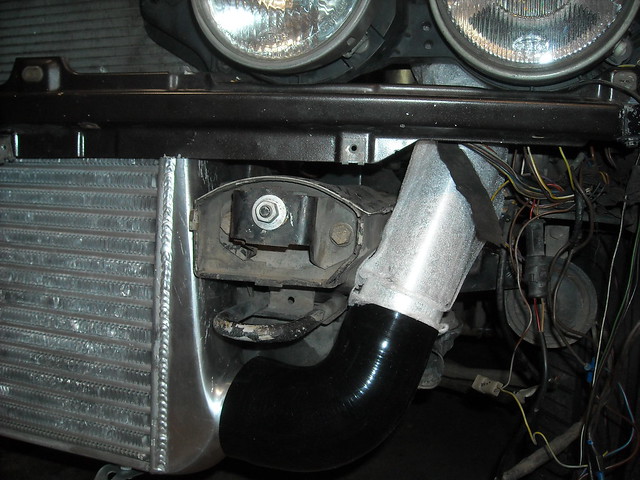

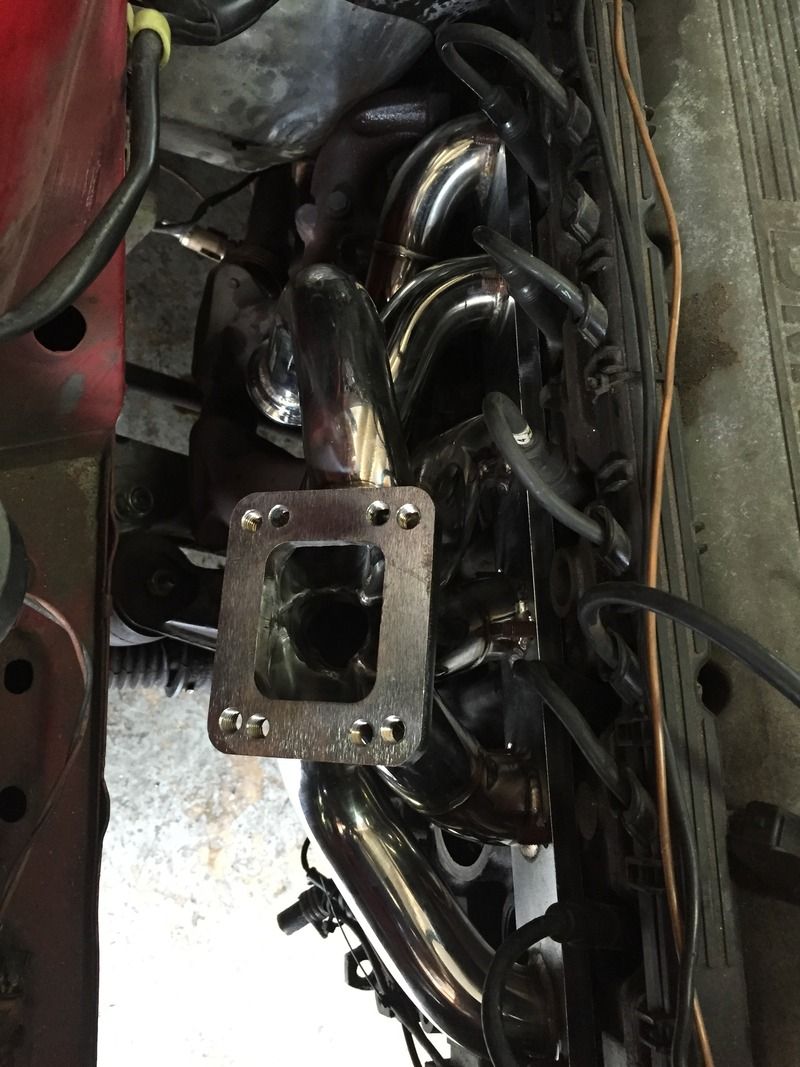

The car is very close to starting, but the 2.5" V Band clamp that I got does not quite tighten the turbo to the exhaust. I'm going to get another and see if that will tighten it together, otherwise I'm not sure what I'll do. Its like one side of the clamp doesn't quite clamp the v band lip as tight as the other side.

On to the exhaust. The fart cannon is mounted!

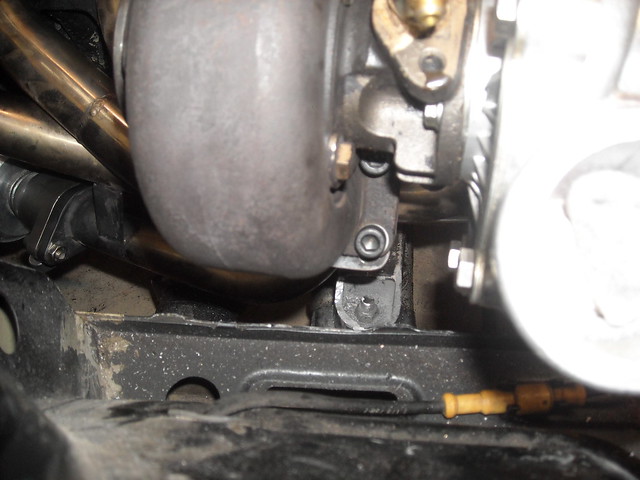

The spacer to go from 2.5 to 3 inch put the downpipe in a perfect location for this exhaust.

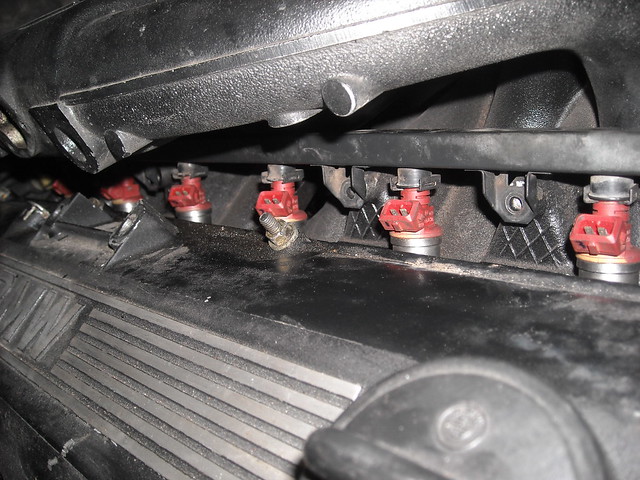

It comes near the LCAB but there is a shield here.

It is about as tight to the body as possible for an exhaust designed for a rwd e30. This is the cx racing 3" turbo back stainless steel system. It was purchased by the previous owner so I decided to give it a shot.

Comes very close to the mount here but it fits.

Here it barely fits under the rear subframe.

Not sure what this mount is for?

The factory e30 mount fit just right to the mounting position on the exhaust/ fart cannon.

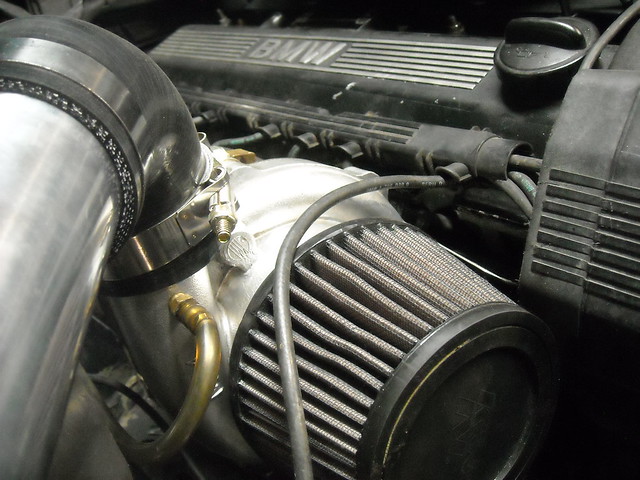

The screamer pipe is mounted and fits well.

And the oil drain is connected.

I also started on the e28 spoiler to get it painted and cleaned up

I may order another 2.5" V band clamp and then a change to my tune is all I need before startup!!

Leave a comment: