Project Lessmeister: 91 318iS Restomod w/ MTech2 and modern drivetrain

Collapse

X

-

Hmm yes updates....

Every time for the last couple days I've tried to sit down, upload new pictures, and write a bit Photobucket has either been outright down or experiencing problems.

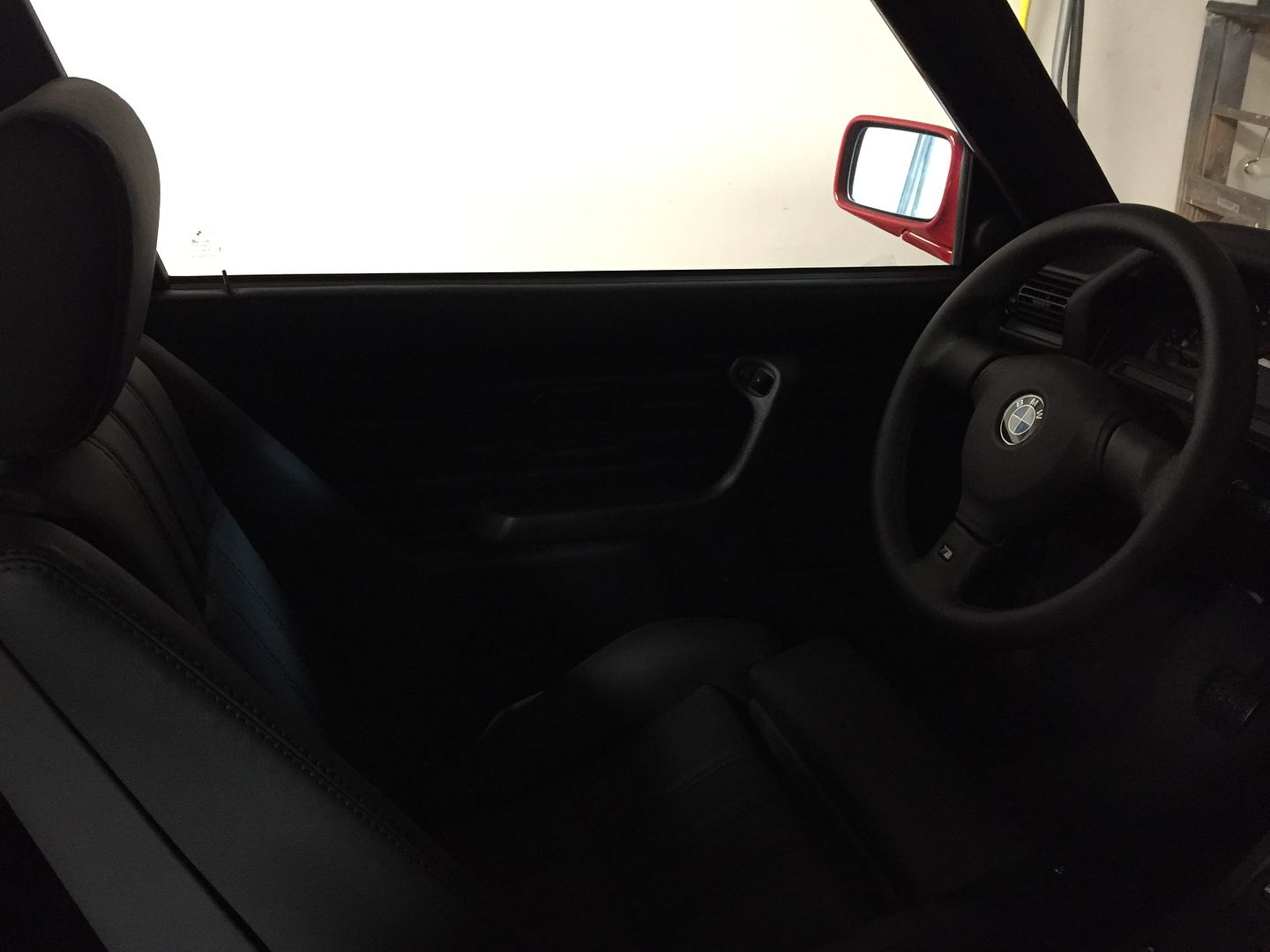

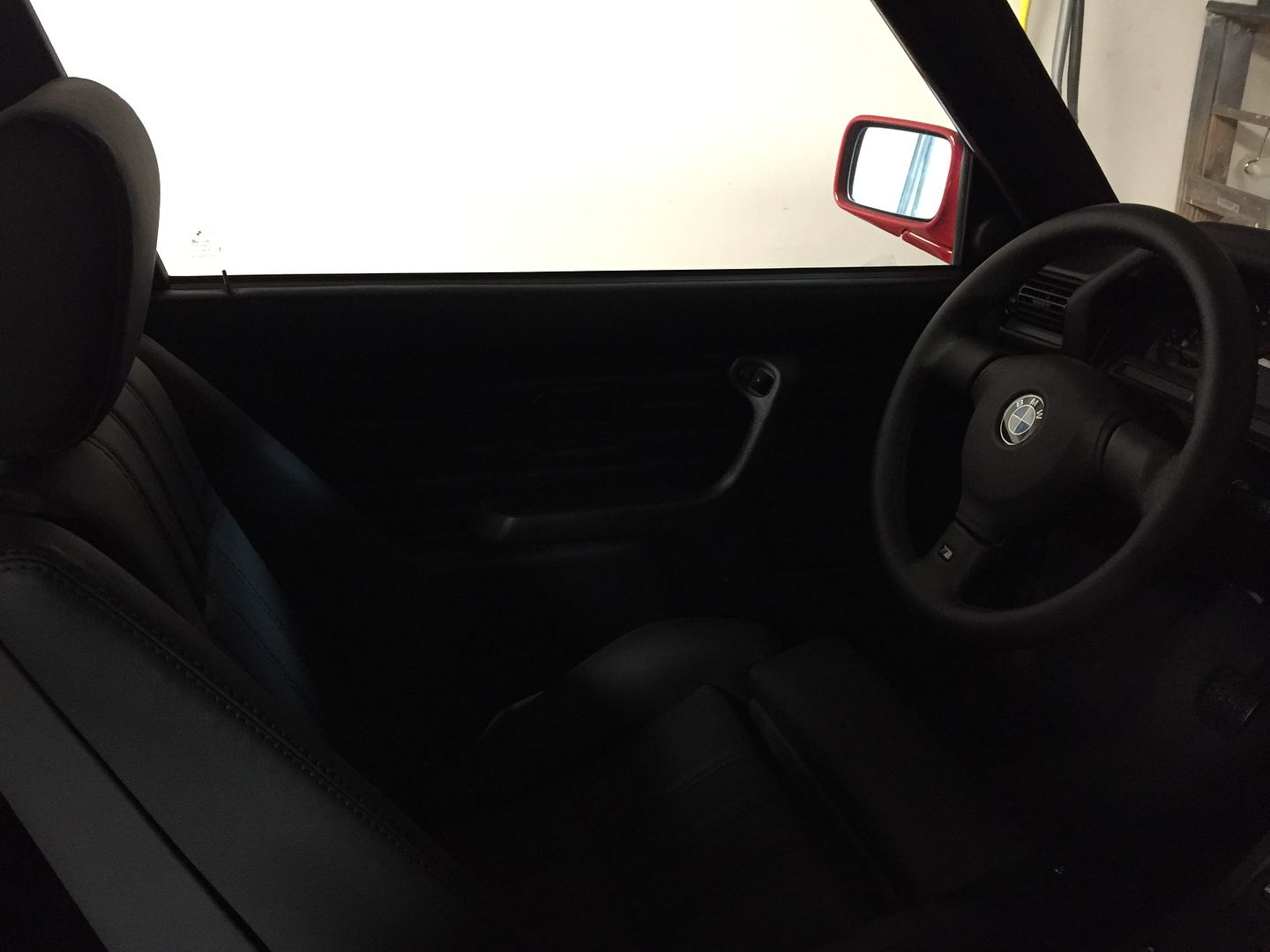

Here are a couple interior pictures I took.

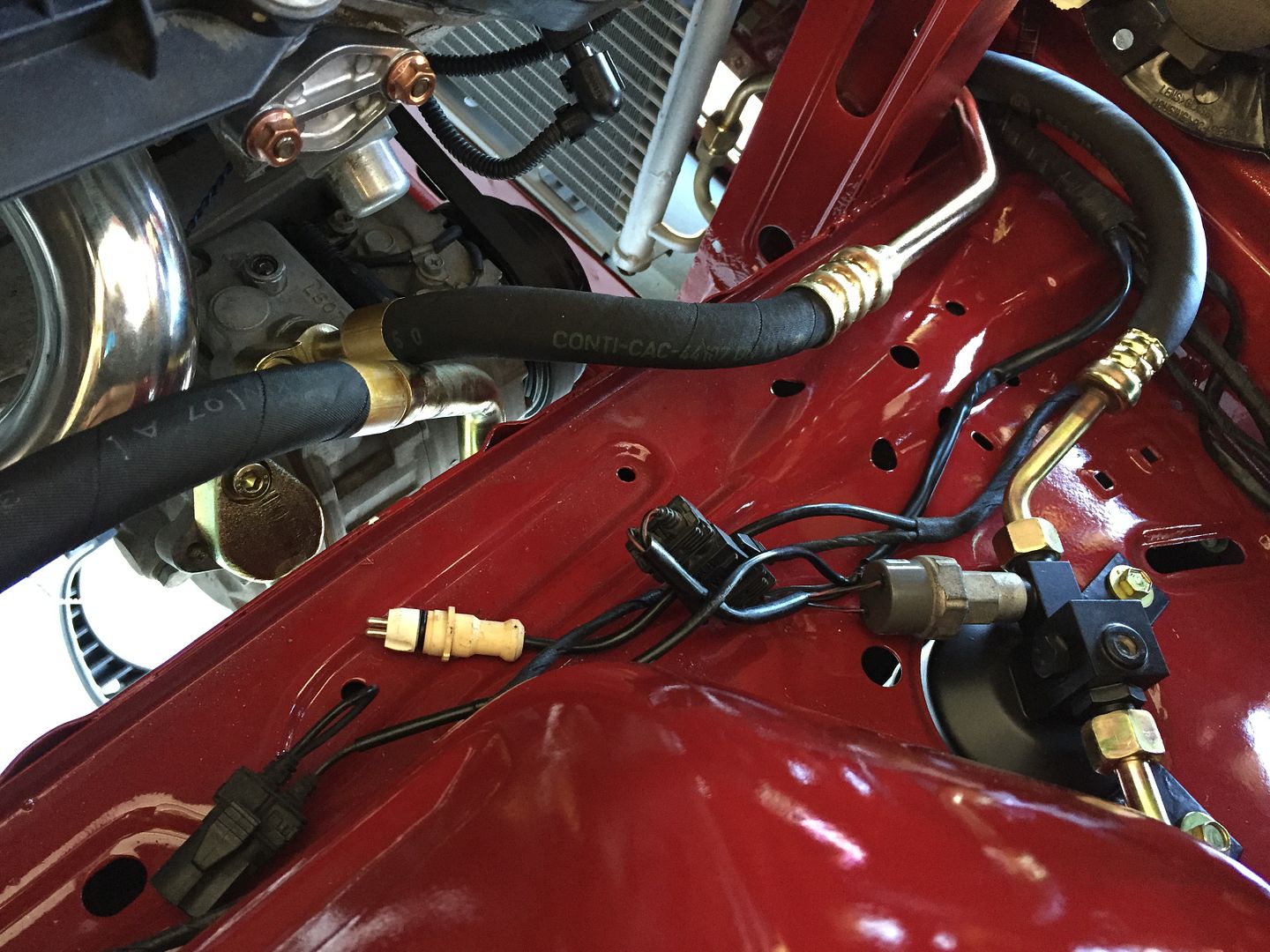

I fabricated the AC lines earlier this week and had them crimped together.

I then sent the lines and a handful of hardware overlooked on the last run out for plating.

AC fan installed on the Nissens parallel flow condensor.

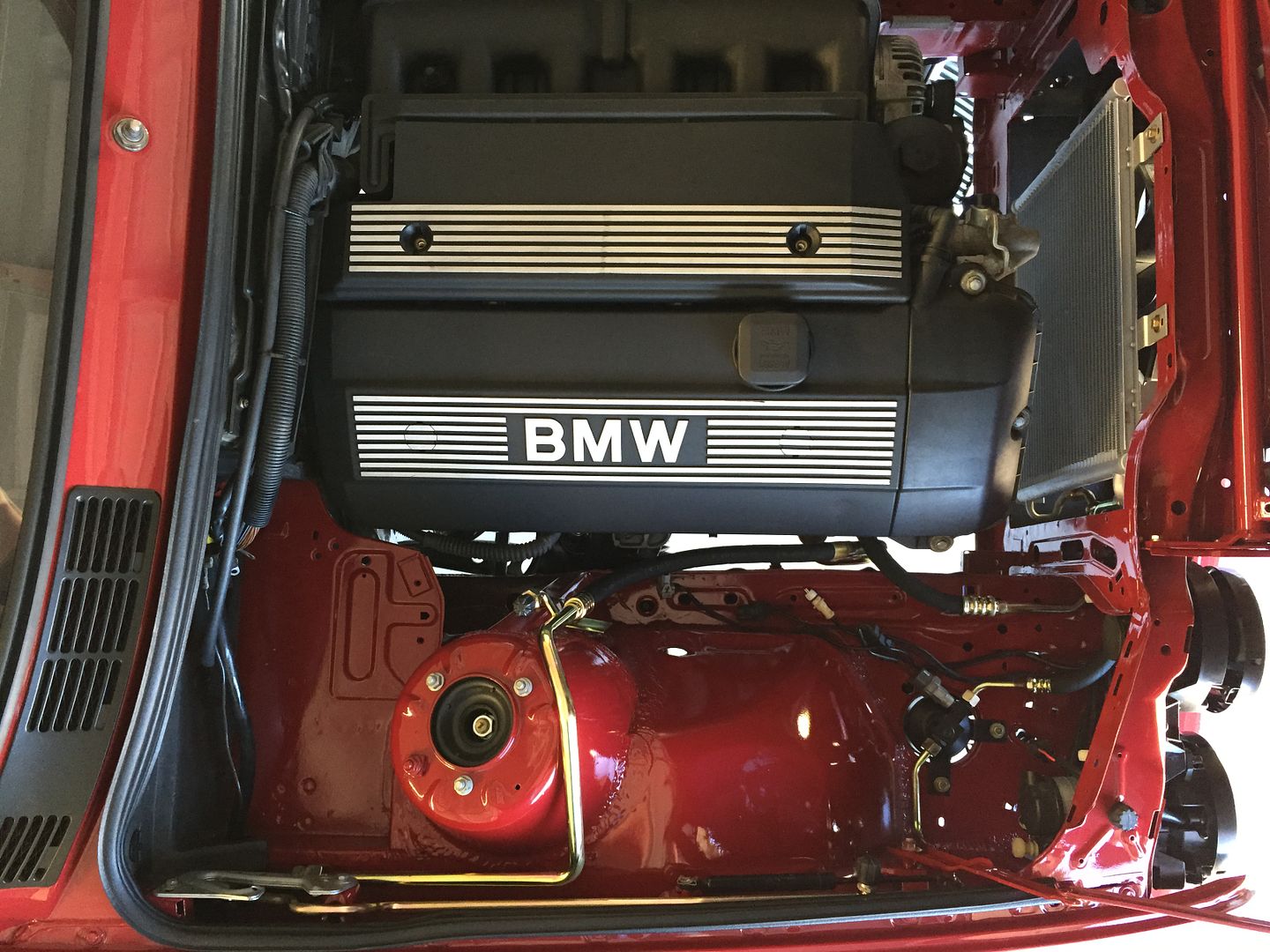

AC system installed into the car, less the loop hold downs which I need to buy new.

No matter how much I heated and bent the secondaries on the headers they just did not fit well and I wasn't happy with them. I decided to cut them at the collectors, weld on vbands, and fabricate down from there.

I pulled the headers back out last night which wasn't much fun.Leave a comment:

-

This is a high quality build for sure. Enjoying following the process.Leave a comment:

-

-

Jordan, there is a speck of dust on the engine cover. You have disgraced this forum. I hope you feel bad. ;)

;)

Leave a comment:

-

Yeah, if you are using a GS6-37BZ it will be. Really any 6 spd is going to be short short in an e30.

I'll post better pictures of the AC lines after they get crimped and plated.

Another day of little things, its all adding up though.

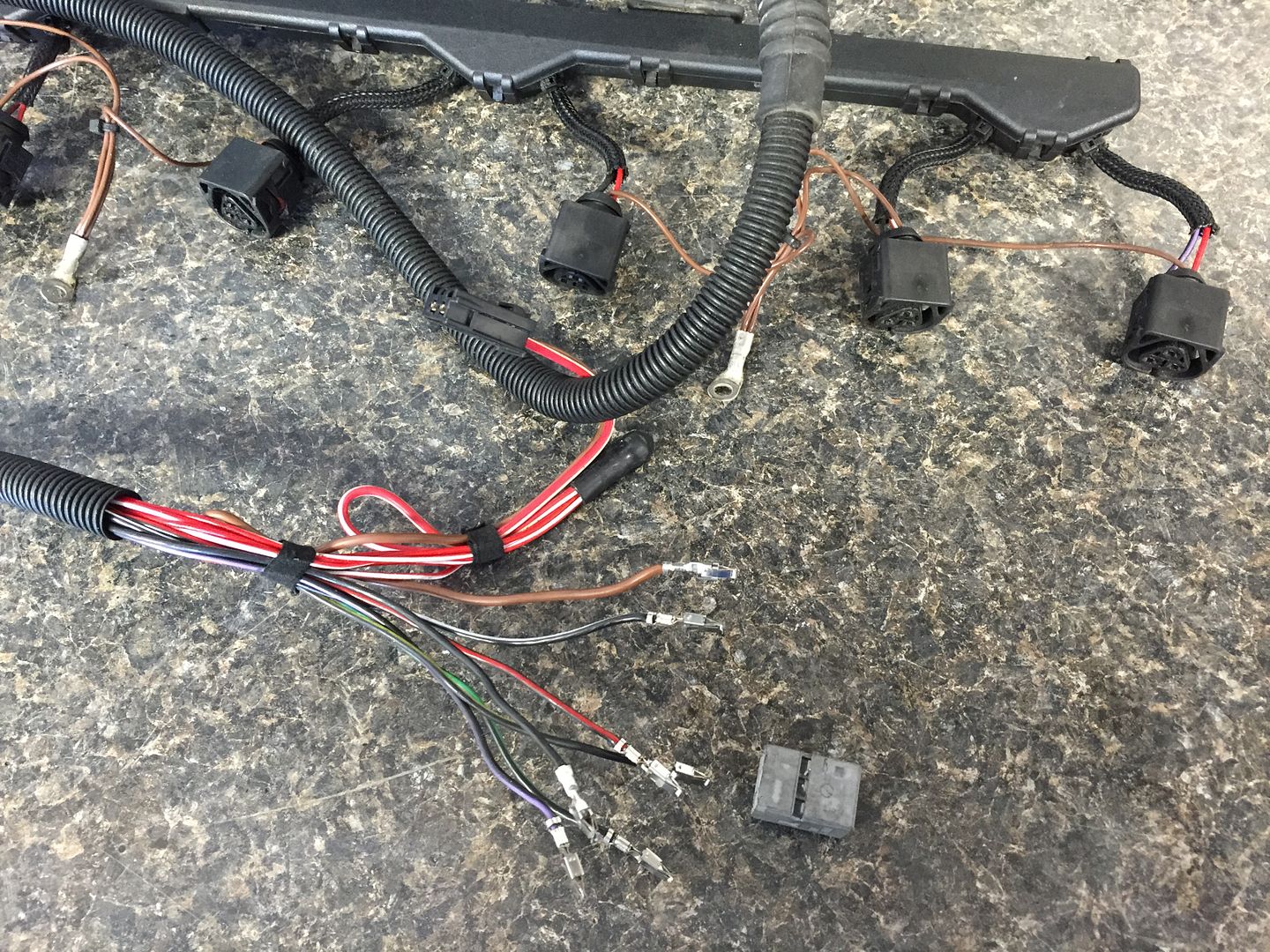

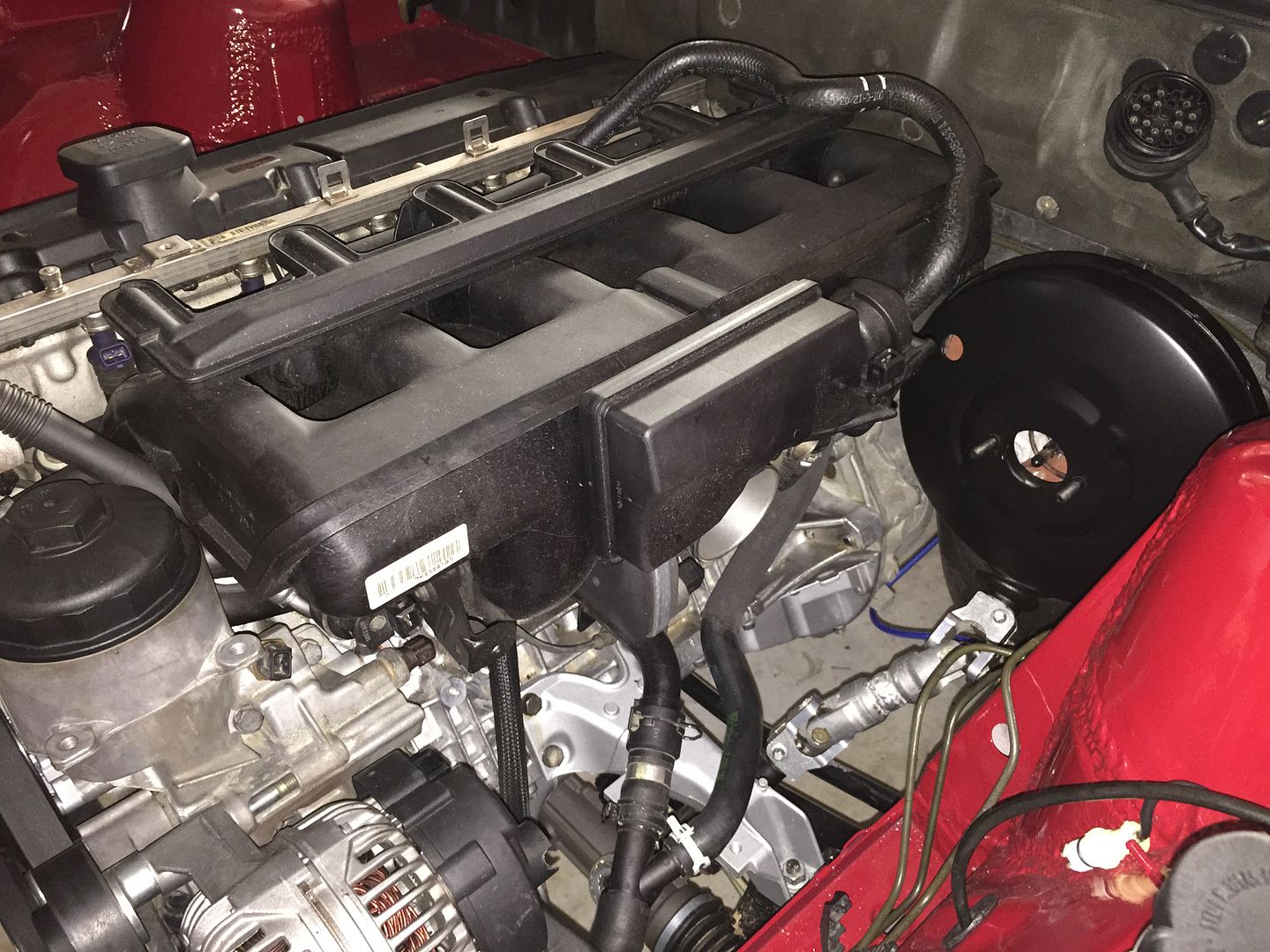

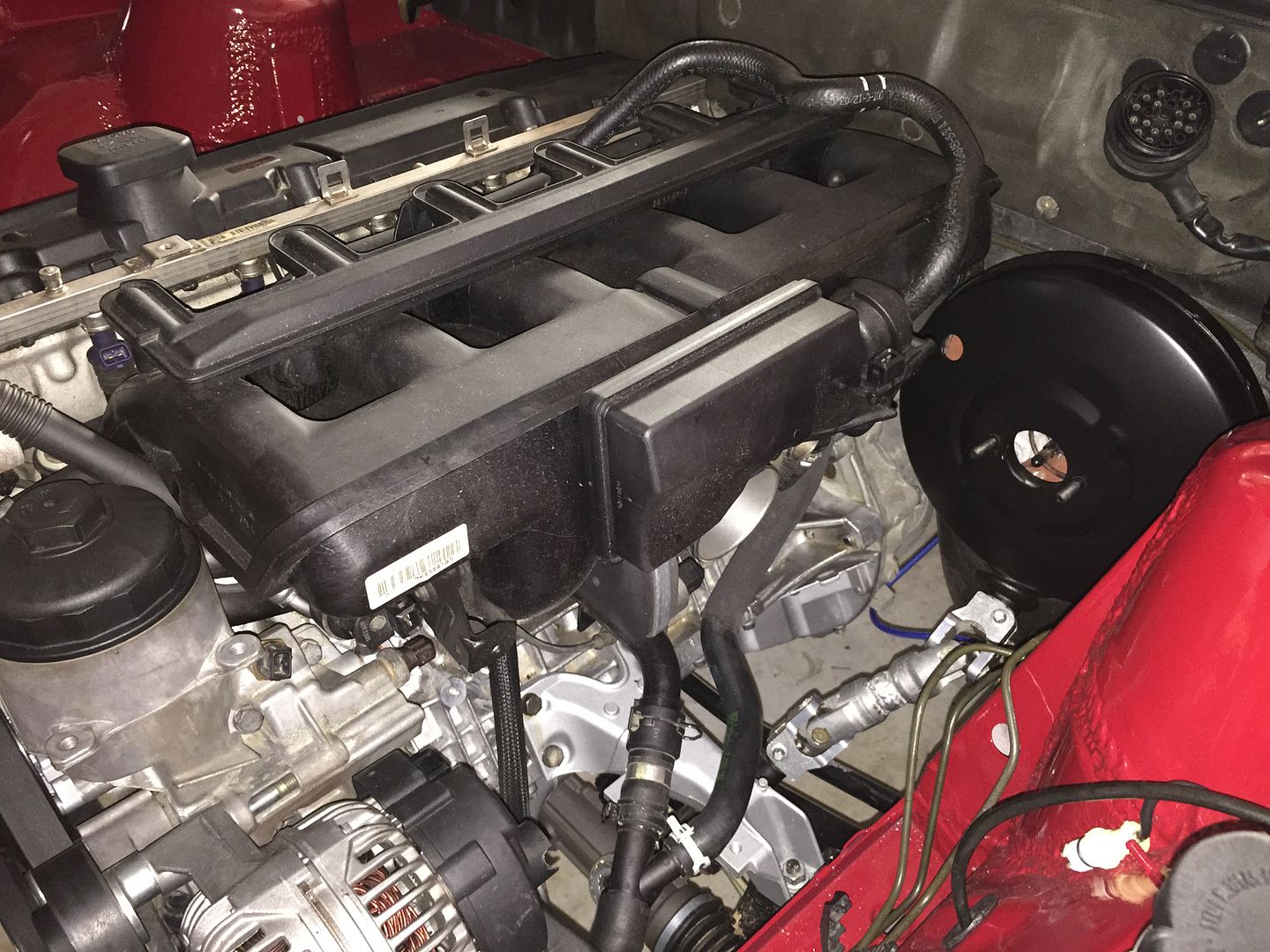

First task today was to wash and dry the MS43 engine harness. This was taken from a 2001 E39 530i. Plenty of slack to reach the glovebox. After it was clean and dry I fished an additional wire through the harness to the passenger side to reach the coolant temperature sensor that will replace the drain plug for the coolant temperature gauge.

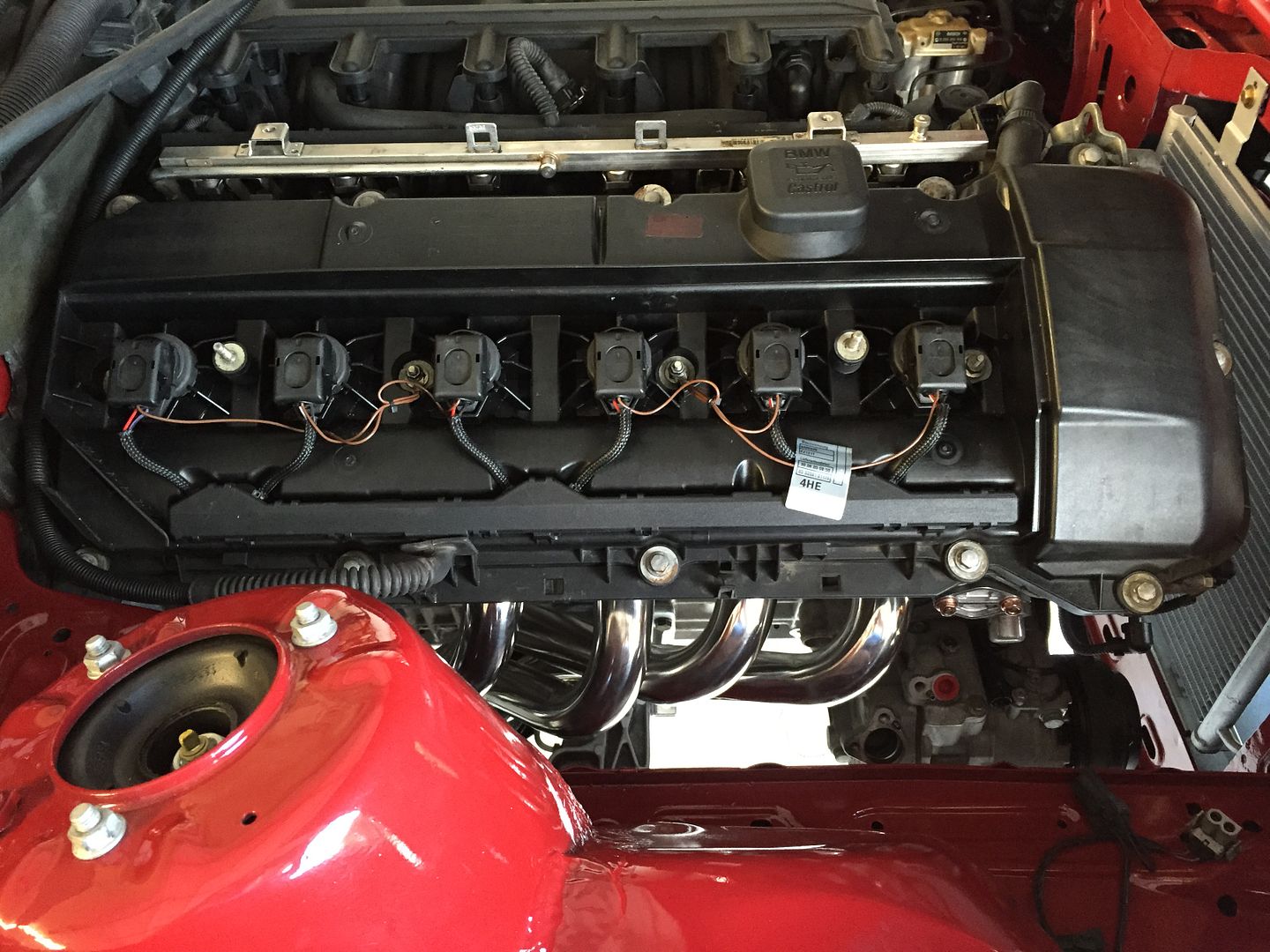

In place, starting to route and button up

Since I am using the MS45 valve cover and pencil coils I have to repin the MS45 coil harness to mate to the MS43 DME. The connectors at the DME are the same, however the only pin that is shared is the ground. For whatever reason Siemens changed the pinout and moved each coil wire to a different slot. Not a big deal, 7 wires to remove and reinsert in the correct holes.

Coil harness installed on the engine

Harness leads tied up to the firewall cover, engine covers laid in place to make sure everything fits fine, it does. Sure makes the engine look nice and tidy.

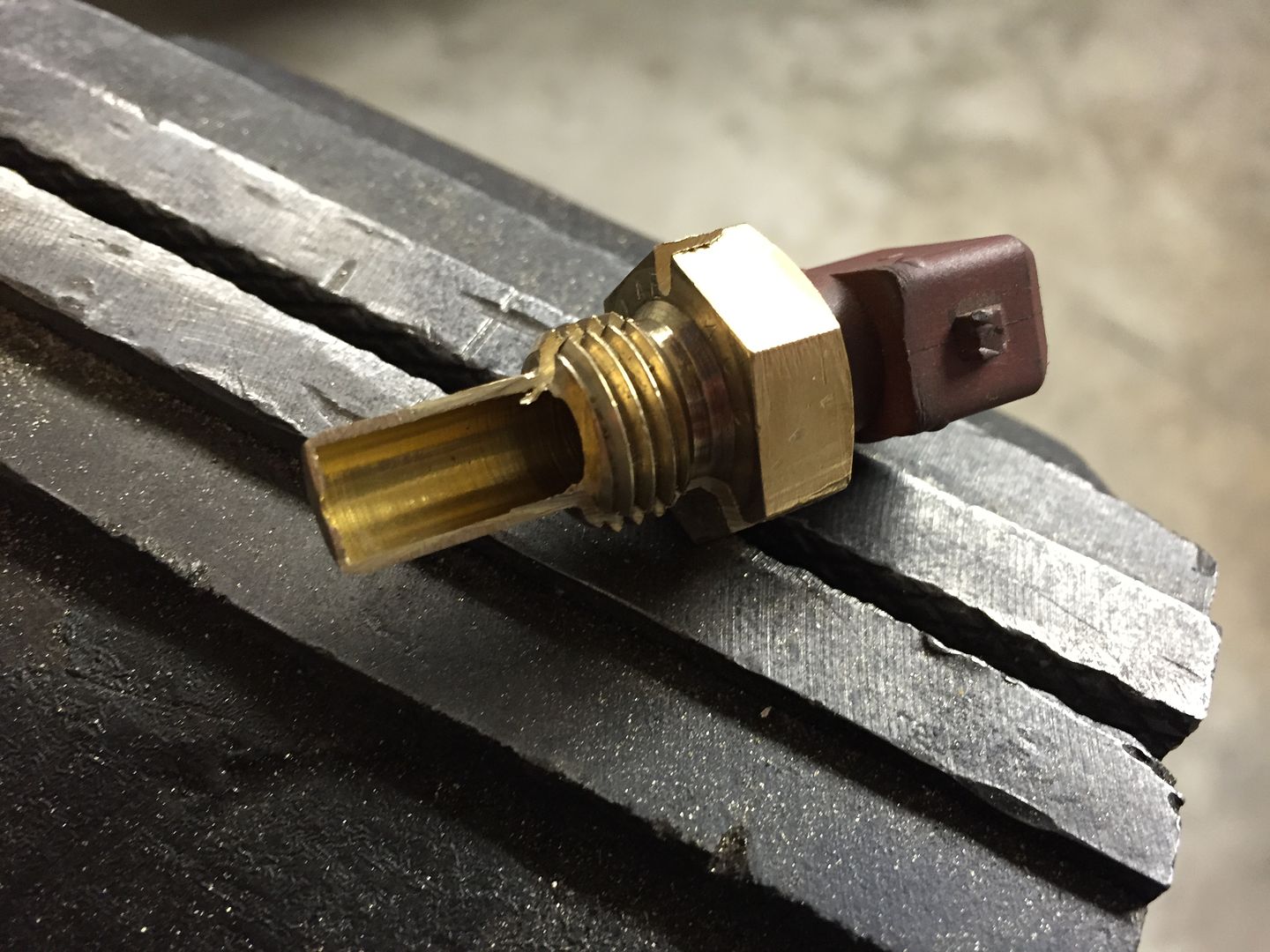

I went to install the FAE brand coolant temp sensor in the drain plug hole and found it hit the cylinder wall. Ugh ok... uh... A quick search revealed this was an issue and apparently the fix was to double up the crush washer. I'd rather not.... so I decided to shave down the end a little. I got it where it was about 1/2 turn from tight and then shave it down a little more... too much.. into the inside of the sensor... whoops.

Since it was ruined I went ahead and cut it in half so I could make some measurements and not eat the next one. They are only $6 so no big deal. I'll modify the replacement carefully based on the dimensions of this one.

While I was under there I decided to deal with the 4-5-6 rear bank header, which is touching the firewall heat shielding. These eBay headers used to be a better quality product IMO. None of the other half dozen or so I've installed over the years had this issue, but again a quick Google search revealed this is becoming a common problem now. Several people complained of touching, or outright conflict between the headers and firewall.

I placed my biggest pry bar between the frame rail and the header, lifting it with my floor jack to put some tension on the pry bar. Doing it this way gave tremendous mechanical advantage over just putting it in the header and tugging. I fired up my MAP torch and headed the header just under the collector up cherry hot while my step son pumped the jack, driving the header down off the firewall with each pump.

I left the jack on it while it cooled, and it stayed more or less where it was bent to when released. Excellent.

One problem solved, but another noted. The O2 bung on that bank points straight at the firewall and does not leave sufficient space to get the O2 sensor in there.... I have spare bungs and plugs, but this means I'll have to take it off to get it welded in place. Ugh....Leave a comment:

-

wow! that shifter carrier is short! is that the same setup i'm going to need? can you post more pix of your a/c lines? i assume you are sending those out for plating too?Leave a comment:

-

It's always surprising to me how fast you can burn through a day and how "little" you can manage to get done despite working non stop.

I starting this morning by unpacking the Z4 shifter carrier and cutting it down to size. Its about a foot too long for the E30 application, but it is the best starting point in terms of overall shape to cut down.

I completely spaced taking an after picture, but I was working on the photos I took on the last E30 I did this transmission in so it should look about the same.

After I finished cutting it down and was satisfied with the mock up of the part I tossed it in the car with a bag of loose hardware and headed across town to visit my friend Wil at IDB Racing to use his blast cabinet again. While I was over there I dropped the shifter carrier off next door with the guys that do my aluminum welding.

About 2 hours later I had all the hardware blasted and headed back home with it. Another solid 2 hours later I had each piece completely cleaned and wire wheel polished.

I decided to go ahead and do another plating run after how nice the last batch came out. Some of these parts will replace marginally perfectly fine original bolts already on the car, some of it is yet to be installed stuff.

After finishing up that task and oiling all the parts I moved to the air conditioning lines. I took a full set of lines from an E30 at work, 2 of which were newer/updated. I also took both lines from an E46 that connect to the AC compressor.

First task was deciding where to cut and join the hoses. I ended up cutting the connector off the E30 low pressure line end and brazing the E46 line end into it. I had to remove the crimp and take the end free else the rubber would have burned. I brought the union up to about 1000F with my MAP torch and fed bronze filler rod into it until satisfied with the coverage.

The high pressure side was a little more simple, just cutting the hose down a bit and slipping the E46 end into it, again sans crimp ferrule.

With all of this done I then went ahead and stripped all of the original yellow zinc plating from all of the lines before polishing them to a nice luster. Monday I will get the 2 I worked on crimped together and then it will all be dropped off Tuesday for plating. The lines should look really really nice when done.

Leave a comment:

-

Jordan, work is amazing! That 944 booster looks perfect. How much more work would you have to do to put an S54 in there with the 944?Nice to know, I try to avoid that store. Ingress and egress from that parking lot sucks and its always slick as snot from the carwash right there. Store also never seems to have what I'm looking for.

There is a Hose Power right near my work that I goto. They are really friendly and didn't charge me to crimp ferules on this hose.

New door vapor barriers installed, yes they are almost invisible!

Door panels, map pockets, arm rests etc installed.

I finished up the Porsche 944 booster as well. Threading the input rod was tiring but straight forward. Sanded it well and have it a few coats of SEM 39143 like everything else. Looks new, clears the manifold and uses the stock master cylinder and reservoir.

The factory body schultz is all in great shape, adding anything on top of that would serve only to increase the cars weight.Leave a comment:

-

Nice to know, I try to avoid that store. Ingress and egress from that parking lot sucks and its always slick as snot from the carwash right there. Store also never seems to have what I'm looking for.

There is a Hose Power right near my work that I goto. They are really friendly and didn't charge me to crimp ferules on this hose.

New door vapor barriers installed, yes they are almost invisible!

Door panels, map pockets, arm rests etc installed.

I finished up the Porsche 944 booster as well. Threading the input rod was tiring but straight forward. Sanded it well and have it a few coats of SEM 39143 like everything else. Looks new, clears the manifold and uses the stock master cylinder and reservoir.

The factory body schultz is all in great shape, adding anything on top of that would serve only to increase the cars weight.Leave a comment:

-

Jordan you going to undercoat the car before you put all the rest of the stuff on?Leave a comment:

Leave a comment: