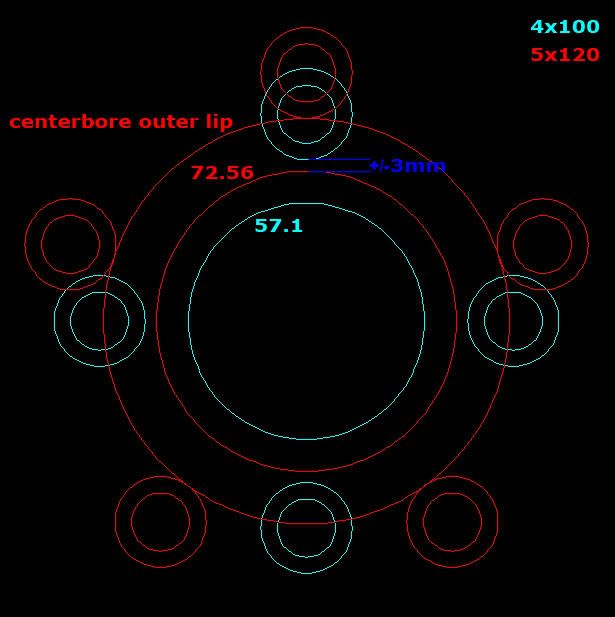

Note that 3 mm is to the edge of the sloped area where to bolt head will rest. That leaves at least another 3 mm to the actual hole.

The guy doing the work has done these before. I was assured that if the specs are closer than is safe we will scrap the project all together.

Comment