I have multiple in the photo because they're different sizes.

There's an o-ring on the driveshaft and another that's a larger size on the snout of the front output gear. The plastic part seals to both to keep the spline grease in.

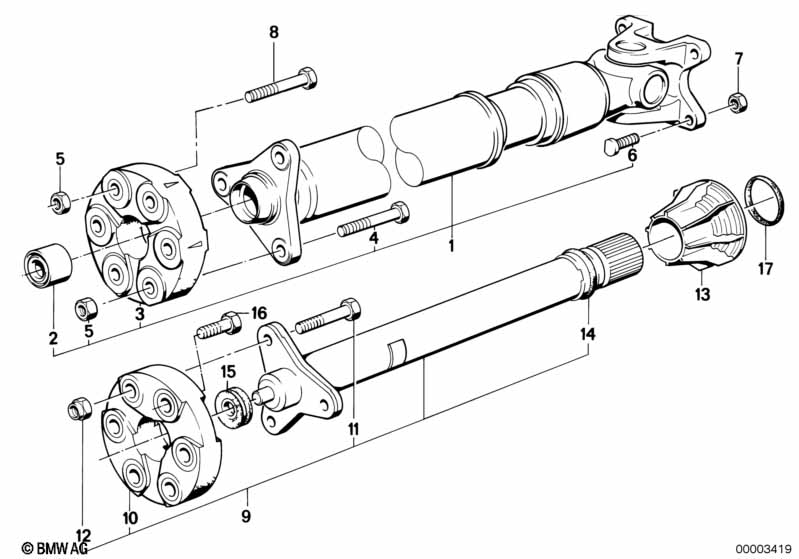

The o-rings are #'s 14 and 17 in the first diagram you posted.

Neither of the o-rings I posted keeps oil inside the T-case. That's seal #27 as you pointed out.

Shift console broke

Collapse

X

-

I have a leak from my transfer case where the output shaft goes to the front diff under this plastic cap. Here is the real oem view. I'm looking at number 17.

These are the o-rings for the driveshaft and sprocket snout, as well as the part number for the plastic "covering cap" that connects and seals the two o-rings. These o-rings don't just keep junk out of the driveshaft splines, they keep the grease *IN*. My o-rings were so brittle they cracked when I tried to remove them. There was a ring of schmutz around the front output from where the grease had leaked out and schmoozed all over the front of the T-case.

Looks like it is a 38x3 mm o ring. Why do you have multiple? I am thinking transfer case output shaft seal. Any other 'while you're in there's' that I should replace? This is on my turbo so I definitely don't want leaks as it is currently slinging onto my 3" exhaust.No. Description Supp. Qty From Up To Part Number Price Notes

01 Drive Shaft 1 01/1989 26111225684 $736.92

02 Centering sleeve 1 01/1989 26117526611 $11.32

03 UNIVERSAL JOINT LK=78MM/D=110MM 1 01/1989 26111225624 $92.56

LK = bolt hole

04 Hex bolt M10X50/8.8 6 01/1989 26111225054 $2.73

05 SELF-LOCKING HEX NUT M10 6 01/1989 07129964672 $0.36

06 KNURLED BOLT M10X25 4 01/1989 26111206718 $2.18

07 SELF-LOCKING HEX NUT M10 4 01/1989 07129964672 $0.36

08 Hex bolt M10X50/8.8 3 01/1989 26111225054 $2.73

09 DRIVE SHAFT FRONT L=648MM 1 01/1989 26201226183 $423.67 +core

10 UNIVERSAL JOINT LK=78MM/10 1 01/1989 26201701094 $57.29

11 Hex bolt M10X42 3 01/1989 26111204215 $2.02

12 SELF-LOCKING HEX NUT M10 3 01/1989 07129964672 $0.36

13 Covering cap 1 01/1989 26201226007 $6.55

14 O-ring 1 01/1989 26201225676 $1.39

15 RING COVER 1 01/1989 26201225981 $1.20

16 Hex bolt M10X32 3 01/1989 26201226104 $1.66

17 Gasket ring 38X3 1 01/1989 26201701106 $0.61 ENDED

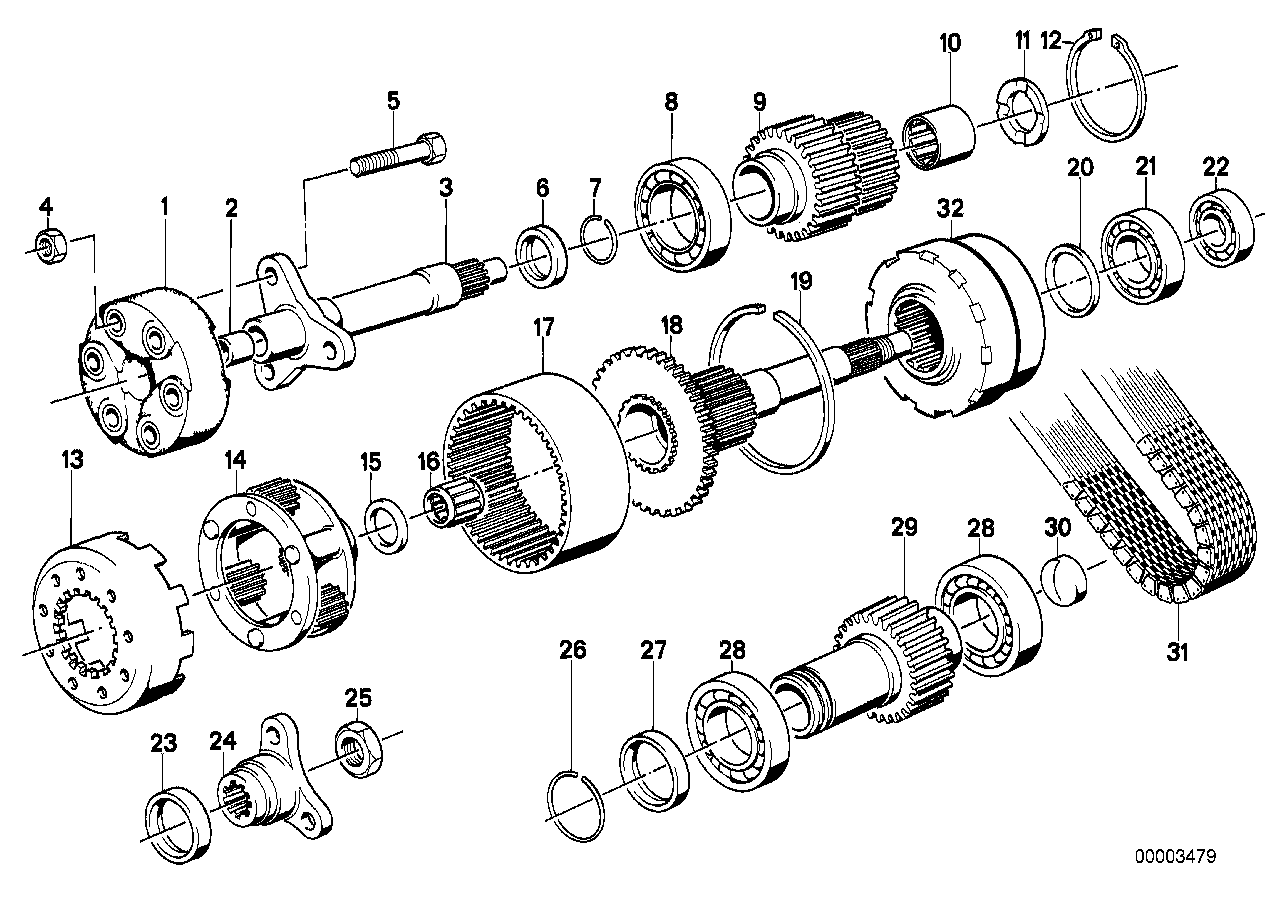

Here is the diagram for the t-case outlet.

Great thread with information on the topic, looks like I need 2 seals. #27 above

Part number 27241224660Leave a comment:

-

It's all back together and works... even still handles clutch dumps from the limiter :-D

The high speed driveline vibration is less than it was. I guess I'll have to hit the subframe bushings next.

Ninja edit: I can't get the plastic piece to slide far enough over the driveshaft o-ring to engage the clips that hold it to the T-case sprocket. Interesting. I may just need to try some spray silicone on the o-ring.Leave a comment:

-

-

Got a hold of my dad.

M10 Class 8.8: 34 ftlbs

M10 Class 10.9: 53 ftlbs

M12: 91 ftlbsLeave a comment:

-

Does anyone have the rear driveshaft guibo bolt torque handy?

I @$$ume the front is the same. The Bentley has rear driveshaft procedures, but not front driveshaft procedures. The book's at my dad's house and he's out right now.Leave a comment:

-

I'm following what the guy I linked here said: http://www.r3vlimited.com/board/show...31&postcount=4

I have the parts, but as I was cleaning the old red grease off my driveshaft splines I discovered that they're not in such good shape as I thought. I'll grab my dad's old driveshaft that he liberated by going to the multi-piece driveshaft I showed here: http://www.r3vlimited.com/board/show...&postcount=391

Once I get that shaft from my dad's house, I'll put the front driveline together and take some pics of how the guibo turns out. The guibo recommended above is the same PN as the rear driveshaft guibo.Leave a comment:

-

I did. I went with the garagistic 325ix DSSR. front and rear delrin carrier bushings, and a new shift cup bushing as well.

Off topic, but how can i make sure I get the proper front guibo? both front guibo and drive shaft guibo are fairly ripped and I'd like to make sure I'm getting the right one..Last edited by driftxsequence; 08-21-2016, 01:08 PM.Leave a comment:

-

That's exactly what we ended up doing. I did have a helper raising and lowering the transfer case.

shifter slop is nearly all gone. Well worth the effort.Leave a comment:

-

Trans was lowered. The shifter has to be dropped in order to reach through the shifter hole with a tool and this can only be done with the T-case and trans lowered.

The T-case is ~60# I think... I'm pretty strong and removed/installed by hand under the car. If you're not a beefcake, you probably want something to hold it up. It will mostly stay in place via the alignment dowels and guibo centering pin, so you shouldn't have to be supporting it's weight while you get a bolt in. I was able to start both of the top bolts from underneath and run them all the way down with my fingers, then come from above to tighten them.Leave a comment:

-

Thanks for the great photos. I am trying to drop my transfer case and those top bolts are a pain. Did you have the trans lowered or raised when breaking the bolts loose?

Should I have a jack to catch the t-case or is it man-handable?Leave a comment:

-

I elected to forego the DSSR this time around.

You can see the end of the shift shaft above the trans output flange in this photo:

This shows the new (wire lock) vs. old (band lock) rod joint, as well as the other shift linkage parts. The orange thing is a foam cushion that goes into the rod joint before it is installed on the shift shaft.

Like this:

Rod joint installed:

Shift linkage assembled:

You can see the clips on the side of the shift support rod which hold the back up light wiring into the channel on the side of the rod.

The intricate features of the installation interface of the manual transmission transfer case.

Rotated the input shaft to see more of the craziness:

These are the o-rings for the driveshaft and sprocket snout, as well as the part number for the plastic "covering cap" that connects and seals the two o-rings. These o-rings don't just keep junk out of the driveshaft splines, they keep the grease *IN*. My o-rings were so brittle they cracked when I tried to remove them. There was a ring of schmutz around the front output from where the grease had leaked out and schmoozed all over the front of the T-case.

Last edited by The Dark Side of Will; 08-20-2016, 04:03 PM.Leave a comment:

-

I don't recall if it was narrower. But I know it didn't fit with the DSSR, it wasn't even close.Leave a comment:

Leave a comment: