so, i decided to get cracking on my seats, took my back rest to work and got started on striping the seat and rebuilding the rubber (foam).

this is what i started with:

this is what we use to trim and cut rubber, its basicly an electric knife,

after i cut out all the all the bad stuff,

then i cut a piece of 3" rubber and cut out a spot for the rail,

then glued it on, we use a presurized container with an industrial adheasive,

then backed it with 1/2" rubber,

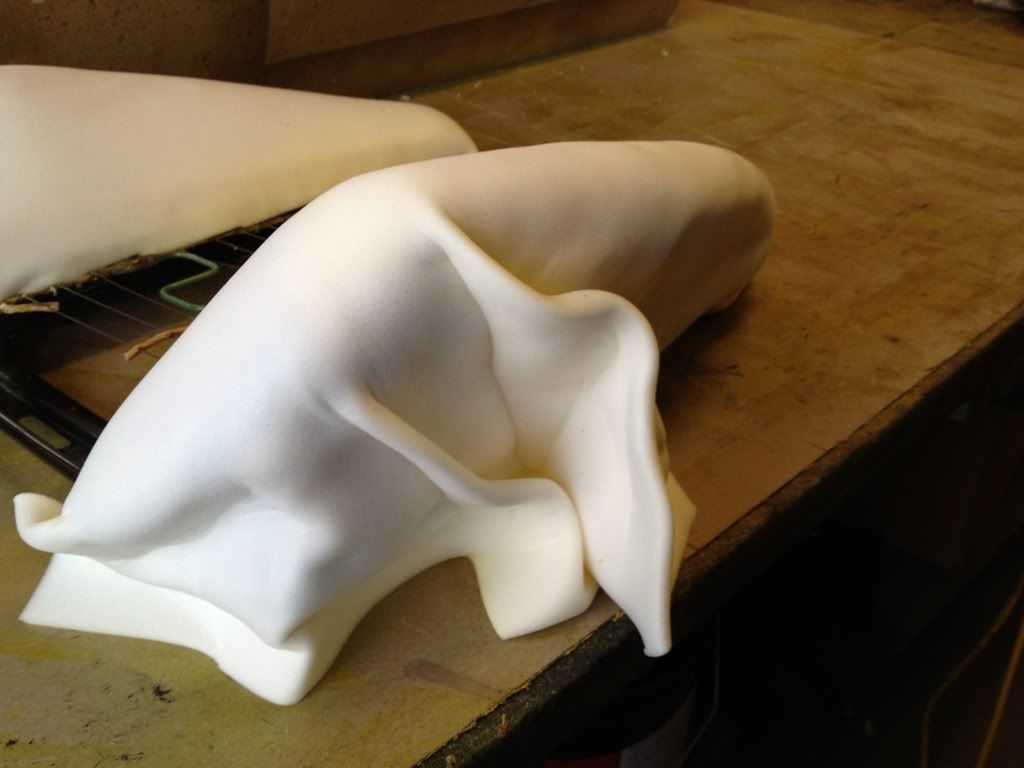

now the hard part, this is all done by eye and experience. im still learning this part, but is very artistic, its basicly sculpting, a word of advise, go slow, take very little at a time.

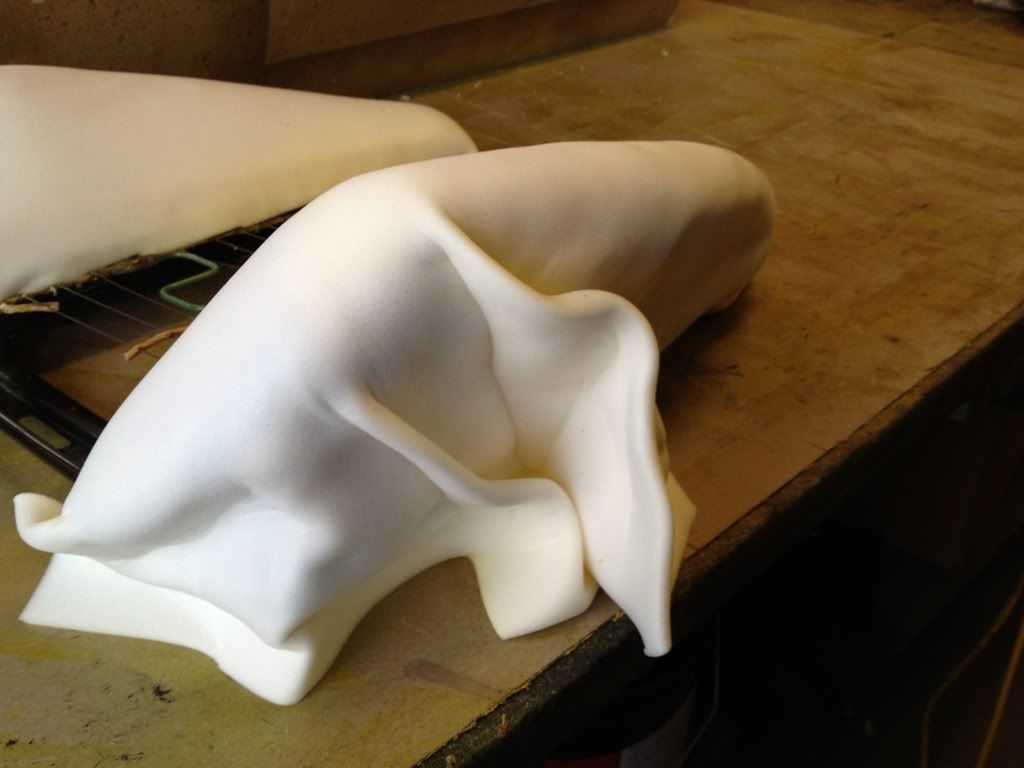

once i feel like its close enough, i cover both pieces of rubber with 1/4" rubber, it smoothes out all the imperfections, and brings back some of the size that the ruibber has lost over the last 20 years,

well thats as much as i got done on friday, maybe this week ill get to paterning and sewing.

this is what i started with:

this is what we use to trim and cut rubber, its basicly an electric knife,

after i cut out all the all the bad stuff,

then i cut a piece of 3" rubber and cut out a spot for the rail,

then glued it on, we use a presurized container with an industrial adheasive,

then backed it with 1/2" rubber,

now the hard part, this is all done by eye and experience. im still learning this part, but is very artistic, its basicly sculpting, a word of advise, go slow, take very little at a time.

once i feel like its close enough, i cover both pieces of rubber with 1/4" rubber, it smoothes out all the imperfections, and brings back some of the size that the ruibber has lost over the last 20 years,

well thats as much as i got done on friday, maybe this week ill get to paterning and sewing.

Comment