the tonneau / lid motor is pretty easy to replace and not very expensive - that's the motor that doesn't break :-)

as to gear grinding, check the angled part in the pic above, it's basically a transmission for the lid motor mechanism. I suspect the motor gear is fine.. honestly I've never seen a lid/tonneau motor with the motor attached gear damaged.

Automatic convertible realignment procedure

Collapse

X

-

After a season with a semi-manual top I'm going to try to fix the motor/gear assy to get back to a motorized top. My original problem was a gear stripping sound as the tonneau cover raised. Once the tonneau cover is up, the top motor seems to work fine, although I have to help fold the top due to a lack of elasticity in the top straps which is common.

Has anyone tried to disassemble this tonneau cover motor assy? I am trying to get to that gear which probably requires removing the black bracket. How that bracket comes of isn't clear so before I try more

aggressive measures I'm checking to see if anyone has done it.

The gear you can see in the background is available on eBay so I suspect that may be the gear that's grinding.

To access the gear I need to hinge the two mechanisms apart.

I will document this if it works out. There's not much out there on repairing these automatic tops due to the small number of them sold.

Leave a comment:

-

Hi. I’ve put the car in storage for the winter and haven’t had time to start working through the possible problems. The suspension upgrade and power steering leak have the priority right now. I will share any information as I learn something.

Thanks.Leave a comment:

-

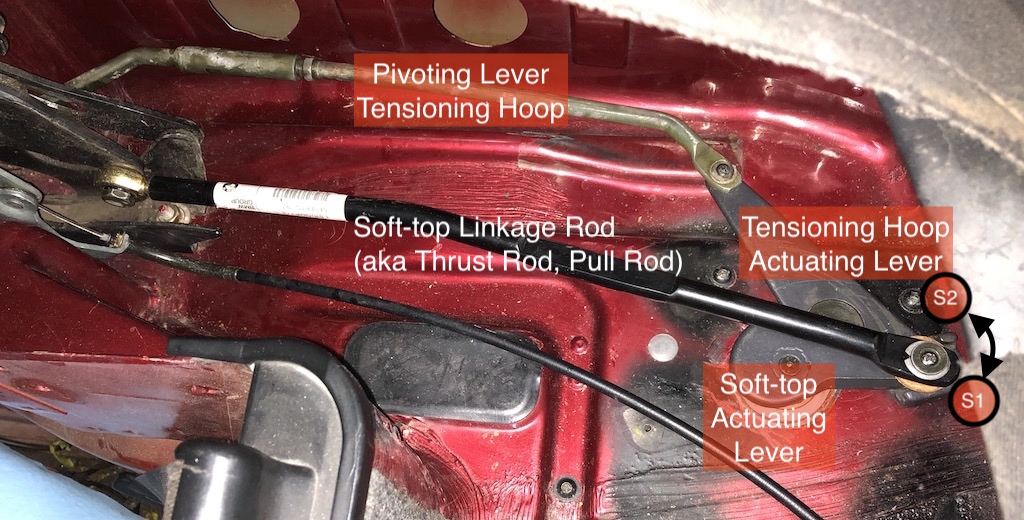

great example of how strong the motors are. I picked up a severely bent pull rod from an r3v member a while back which I was unable to reuse. that's why the thrust rod in the pic is new.

here's another example of how strong the motors are - the top of the motor housing is broken here (right in the center of the pic). This is a very common problem that was caused over time by the top frame itself not moving freely, and eventually cracking and separating the attachment point to the top motor housing. THere's no way for the top motor to move the tensioning hoop now, so the top can't move and the lid motor can't engage. Only recourse (until the motor housing is repaired or top motor replaced) is to disconnect the top and lid motors. Most driver quality electric top cars are like this, and have been converted to manual operation.

Last edited by bradnic; 11-01-2018, 01:47 PM.

Last edited by bradnic; 11-01-2018, 01:47 PM.Leave a comment:

-

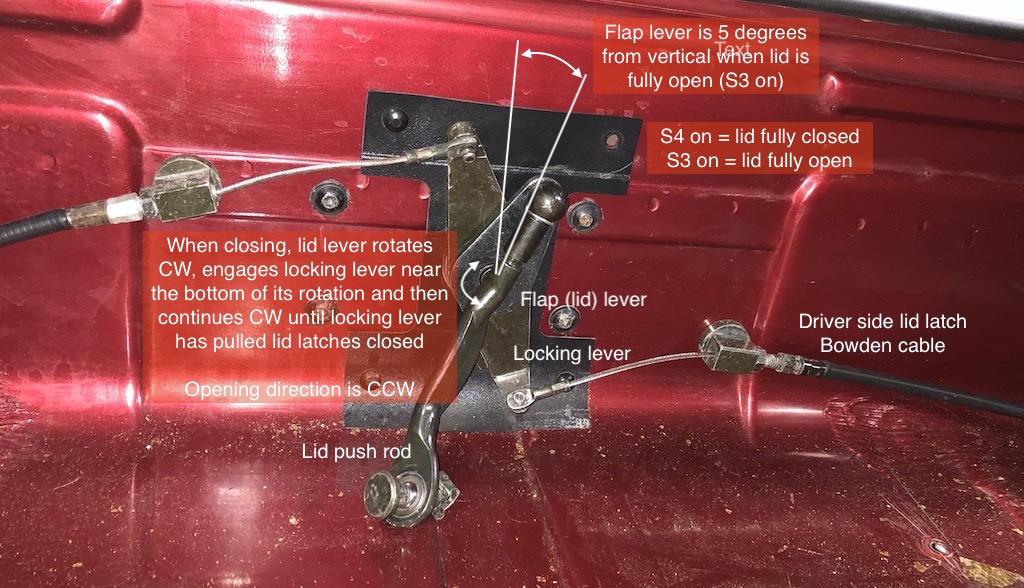

There's no reason that link should be bent back to front. more likely your flap lever needs to be moved clockwise a bit. note the comment in my diagrams about 5 degrees from vertical.

My cover would not close tight when i got my car. I adjusted bowdens and fiddled with the motors without benefit until i finally took this arm off and put another 5-10 degrees of bend in the direction of the blue arrow. Now it doesn’t touch the car and the cover closes down tight. It seems that the motors can be strong enough to straighten that arm over time.

Sent from my iPhone using Tapatalk

Note there are TWO levers for the lid motor. the lid lever and the locking lever. The lid lever is keyed, the locking lever has a rib on it that is caught by the lid lever as it rotates. The S3 and S4 microswitches determine when the levers start and stop. be careful messing with them. If your lid did not fully close, either the locking lever did not rotate far enough, the Bowden cables are adjusted too long, or as a last report the latches need to be repositioned. You can also change the length of that rod, but it's unlikely you would need to do that to the original link. These last two causes are unlikely if the install has never been messed with.

As mentioned the motors have VERY high torque. they can bend the levers severely. sometimes you need to bend them back to shape.Last edited by bradnic; 11-01-2018, 01:46 PM.Leave a comment:

-

Until i figured out the importance of the tension straps to pull the top back slightly, my motors would bend this thrust rod another 20 degrees and I’d have to remove it and straighten in on an anvil. That rod is 3 times the diameter.

Sent from my iPhone using TapatalkLeave a comment:

-

Got it. I was planning to lubricate all the joints this winter, as well as change out the struts/shocks. Fortunately the ragtop days are about over here so I have some time to work on it.that's not good. you either have damaged gears or the lid motor is not fully locked in. DO NOT keep pressing the top bottom if your top or lid stops moving before it should.

have you greased the top mechanism at all? there are a couple of slots on each side that should be greased. in my case my top frame had sheared bolts in those areas. I have pics of the damage on my thread, and also pics of top motors with the top case broken off.

I'm surprised that steel lift bar could be bent by the forces of the lid motor. I can see how that would improve the interference with the body.

Thanks.Leave a comment:

-

Automatic convertible realignment procedure

[QUOTE=Dspill;4928367]

My cover would not close tight when i got my car. I adjusted bowdens and fiddled with the motors without benefit until i finally took this arm off and put another 5-10 degrees of bend in the direction of the blue arrow. Now it doesn’t touch the car and the cover closes down tight. It seems that the motors can be strong enough to straighten that arm over time.

Sent from my iPhone using TapatalkLast edited by htseng; 10-16-2018, 10:42 AM.Leave a comment:

-

that's not good. you either have damaged gears or the lid motor is not fully locked in. DO NOT keep pressing the top bottom if your top or lid stops moving before it should.

have you greased the top mechanism at all? there are a couple of slots on each side that should be greased. in my case my top frame had sheared bolts in those areas. I have pics of the damage on my thread, and also pics of top motors with the top case broken off.Leave a comment:

-

Thanks for the help!!

I will study your posting closely.

I will post a video as soon as I go back to the car. it's stored offsite at the moment.

But for now....

Picture if you will, the tonneau opening up and visibly struggling until it finally stops lifting parts of the way up (~45 deg) but the motor continues to operate and there is a rat-tat-tat gear noise. If I assist the tonneau's weight then it will continue to raise without the noise.

However, when the tonneau reaches the very top of the open position (also where it seems to be interfering with the car), it will rat-tat-tat because nothing is telling the motor to stop turning. I'm guessing that there is a microswitch issue there so I will try to adjust that gear until this stops. I'm not sure if these two issues are related or the first problem created a new problem. Maybe the "up" switch failed and then created a gear problem.

Then on the way back down the same noise will occur unless I assist the tonneau down by hand.

I believe the motor is pushed all the way in as it's very clear how that plate fits into the slot. As the previous poster suggested, if I was to bend the plate backward 1mm it would result in the motor moving in 1mm closer. However I cannot feel any additional room to push it in if I move the locking slot out of the way so I'm hesitant to start bending things yet.

This top worked OK since new, although it has required some hand adjustments as the elastic bands have worn out. This car is in great shape so I want to preserve the operations.Leave a comment:

-

some pics from my thread that may be helpful

and good info starting at this post

"lid" linkage and motor = tonneau

"top" linkage and motor is the main bits that move the actual top

the bottom part of the top frame is called a tensioning hoop. It's the part that sit on the lid when the top is closed, and swings up so the lid can swing open and closed. S1-S2 switches detect tensioning hoop position. S3-S4 switches indicate lid open or closed. The S5 switch sits on the front right top pin and does not allow the motors to engage if the top is locked.Leave a comment:

-

That tonneau / top cover arm has a tight fit - it frequently rubs against the seal behind it. In fact there's supposed to be a protective boot over that arm.

I would VERY careful about bending anything. It's super easy to break the top motor lid by just holding the top button too long when there's an interference problem. Buddy of mine snapped one of the top rods in front of me, just by closing the top.

I can't really understand what you're describing to be honest. Maybe you can post a video, and you can point out what you're seeing?

If your motors are properly engaged you should have ZERO 'gear skipping'. perhaps you have not pushed the lid/tonneau motor all the way in.

I have a lot of electric top info on my vert thread. check the last couple of pages.Leave a comment:

-

Thanks for the suggestions.

I finally had some time to dig into this today. I am able to connect and disconnect the motors now. The key there was to have the top in the "up" position so there is downward pressure on the tonneau while I'm trying to lock it with the Allen wrench.

I'm still getting the gear-skipping from the tonneau during various stages of the process. If I support the weight of the tonneau while it's going up or down I don't have the gear skipping. However depending on how the micro switches are adjusted the cycle may not stop at the top or bottom of the cycle which results in the same gear skipping and it won't move to the next stage of the process.

I have noticed that the arm that lifts the tonneau seems to have interfered with the body of the car as if it's gone beyond where it is supposed to have stopped in the tonneau "up" position (see picture below).

I wonder if the micro switch that tells it to stop going "up" is not adjusted correctly or not working. I removed the micro switch adjustment cover to see both micro switches. I've seen the instructions that say turn it all the way one way or the other and then turn it back until it clicks. Does anyone have more specific ideas of how these work together?

I did try to bend that plate toward the back of the vehicle but it's quite stiff and I'm not sure it moved much. I think I'm on the right track.

Can I remove and reinstall this entire motor assembly without any major complications to get a better look?Leave a comment:

Leave a comment: