im running a 3.73 now. its great but a little short imo. Waiting on my 3.46 to get here from a member. will report back with details.

2.93 is to tall. it takes to long to get into boost. Thats why I bailed mine. For the freeway tho its still nice.

M42 turbo fact thread

Collapse

X

-

What rear end are you guys using? think i might trade for a 3.73. I got a 2.93 for when I planned on driving to ca but the cars kind of a slug off the line now.Leave a comment:

-

-

-

Well im out of the turbo m42 for now...long story.....so im selling my mani, intercooler, and the intercooler piping for 150. Ill have pics monday or tuesdayLeave a comment:

-

they would love each other. if i dont go the borgwarner route ill go gtx3071.

drunk post thoLeave a comment:

-

Well when they made my FW i had to send my oem on in to them, which they kept, because they said they "lost the drawing for the m42 flywheel." I think they drilled out the FW to fit the m20 clutch and when i pull it off ill have nothing but an expensive paper weight... When i talked to the guy at VAC he pretty much said that if they make it it'll work and I took his word for it.Leave a comment:

-

Lots of good info in here, I'm curious as to how you got the M20 clutch on the M42 flywheel though :p

That is a big difference in the bell housing depths though. I am essentially running all 325i stuff from the block back so hope it will work out ok (325i tailshaft is ~100mm shorter and my engine is moved back accordingly).Leave a comment:

-

just bought an m20 flywheel. waffleswaffleswaffleswaffles it.. Dont ask me what i was thinking when i put an m20 clutch on an m42 fw... now i can quit cluttering up this thread.

waffleswaffleswaffleswaffles waffleswaffleswaffleswafflesLeave a comment:

-

Found this.

Found this article tonight, and thought some of you might find it useful. It's probably been posted before, but I've asked questions that have gone unanswered, that this article answers. So here it is:

(updated and functioning URL)

E30 Getrag 260 interchange and information

Submitted by Dale Beuning on Fri, 2006-12-15 08:29. Firstly, all 'i' motors use a crank position sensor on the front of the crank, all 'eta' motors (super-eta may be an exception) use the 2 reference sensors mounted in the trans bellhousing.

Also, don't try pulling the transmission apart. Most of the shops in this area won't even try to dig into one because you can pick one up at a salvage yard anytime for $300 or $400.

There are a couple of issues using an '86 325e manual transmission in an '89 325i car.

Identify which trans you have early 'eta', late 'eta', or 'i':

a) early 'eta' trans (1983, 1984, 1985 manufacture dates?)

i) 260.0.1270.90 is on the side of the 'eta' trans

ii) shifter mounting about the output flange is only 2xM10 holes for the 84,85,86 style plate mount shifter

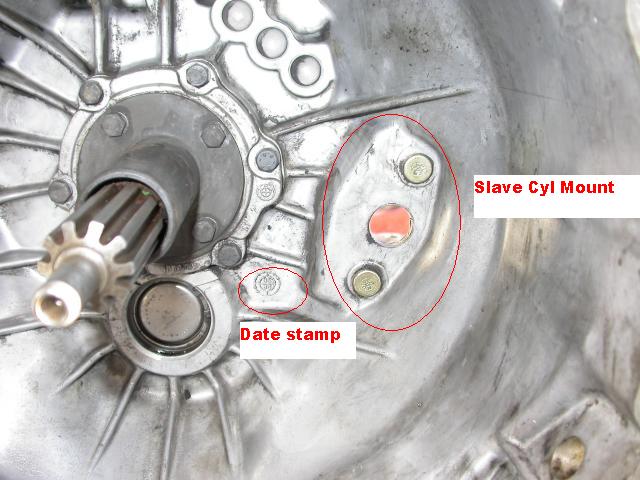

iii) deep bellhousing : Slave cylinder mounting flange = 6 7/8

iv) 2 drilled holes for crank position sensors

v) smaller output flange

b) late 'eta' trans (1986, 1987, 1988 manufacture dates?)

i) 260.0.1270.90 is on the side of the 'eta' trans

ii) shifter mounting about the output flange has 2xM10 holes for the 84,85,86 style plate mount shifter, AND top boss for the aluminum bracket of the 87-91 style shifting mechanism.

iii) shallow bellhousing : Slave cylinder mounting flange = 6 1/2

iv) cast boss for 2 drilled holes for crank position sensors, may or may not be drilled

v) larger output flange

c) 'i' trans

i) 260.0.1346.90 is on the side of the 'i' trans

ii) top boss for the aluminum bracket of the 87-91 style shifting mechanism.

iii) shallow bellhousing : Slave cylinder mounting flange = 6 1/2

iv) no cast boss in bellhousing for reference sensors

v) smaller output flange

If you find your 'eta' 260 trans has the deeper bellhousing, you can correct for it by using a thicker throw-out bearing.

Sachs P/N 21511204525 is a 30mm bearing and will make up the difference.

If you use the driveshaft/guibo that came with the transmission you'll be fine,

the differential end of the driveshaft is the same on all the 6cyl E30s.

There is an early style Guibo(110mm)[26-11-1-225-624] and a late style Guibo(96mm)[26-11-7-511-454], cutover date is 5/86 for end of 110mm, 6/86 is start of 96mm.

6cyl manual driveshaft length 1483mm.

All 3 versions have the same gear ratios:

1 3.83

2 2.2

3 1.4

4 1

5 0.81

Note: If you'd like to use an older version of the 260 with the early style

mounting boss instead of the newer style ears, the E30 M3 came with an adapter

to mount the new style shift carrier to the older style mounting boss.

View it at RealOEM.com

Some pictures of a 'late eta' getrag 260: some images

See the date stamp in the bellhousing in this pic, and also the slave cylinder mounting point to measure bellhousing depth:

This clearly shows both early and late shift lever mounting styles, this has the later style shifter support installed:

Top view of shifter support mount

This shows the part number and sensor mounting points on the bellhousing:

_________________

UnofficialBMW.com Webmaster

dale@unofficialbmw.com

Both of my trans are 260.0.1346.90 so the shallow bell housing.

I remembered that my broken trans was still in the scrap bin. the bell housing depth on it is 190.5mm and the g240 is 174.6.

From this thread I think i should swap to an m20 fwLeave a comment:

-

Thank you strypt. Looks like I might be tearing her down completely..

So just to make sure i dont screw this up, e36 328/m3 zf transmission. Is there a model name for it? like g240, g260, etc. That with an m20 flywheel, clutch and pressure plate. 323i TOB.

Is the 328 e36 driveshaft longer and does it bolt up to our differential?

EDIT: did some research and found that the 318 TOB and 325 TOB are both 1-15/16". trying to find an m20 flywheel to test on it.Last edited by MF DOOM; 06-04-2013, 03:22 PM.Leave a comment:

-

I use the 328/M3 ZF transmission, its much stronger and has smoother shifting aswell. It requires a few mods but nothing too difficult. I use 325 FW, clutch although with a stronger pressure plate and a standard TOB.

I welded two spacers onto the clutch fork, about 8-10 mm I think (can't remember exactly) to get proper engagement, but I think a 323 TOB would work without welding as it is a little bit longer.

Standard E30 transmission crossmember and linkage works without mods (the lower linkage might need a little bend to clear the guibo) but the driveshaft needs to be from a M3E30 (what I use) or from a 328 E36. Only problem there is the spline engagement in the middle of it which is only about 20 mm with this setup. Lengthening the driveshaft would be ideal but I haven't and mine still hasn't broke. A guibo from a M5E34 helps some as it is 5 mm thicker than guibos from M3E30/328/M3E36. If you use the E36 driveshaft you'll need to change the middle bearing to one from an E30.

Oh, and you'll need to change the pilot bearing in the crank as the input axle is a little bit thicker on the ZF.

Edit: You'll need the clutch cylinder from a ZF vehicle aswell.Leave a comment:

-

I cant see why it would be hurting the trans and not the clutch... Woulndt the clutch be the first thing to go out?

Ill get a video of the noise you can hear in the cabin tomorrow.

TOB is a 325 as far as i know. 318 FW, 325 TOB, PP and clutch disk. Ive tried getting ahold of vac to see what they think and to see my order history(nothing shows up when i log on their site) but I never get replies from them.Leave a comment:

Leave a comment: