Broke this s.o.b. putting my valve cover back on after an adjustment. It didn't want to tighten, kept rotating, 'til I snapped it off :(

I got the broken one out, when I get a new one how do I put it back in without damaging the thread?

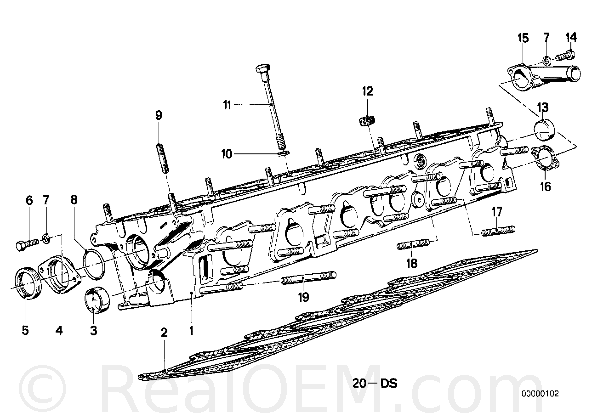

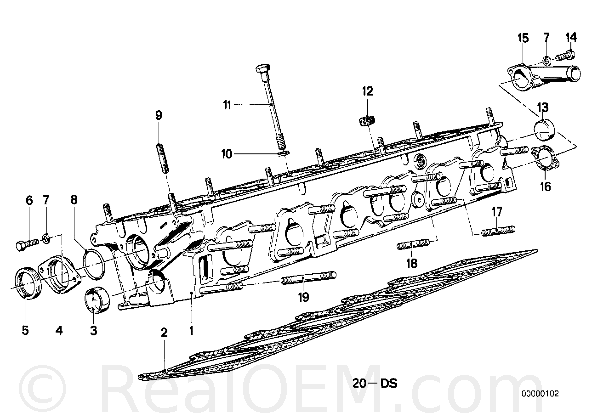

Broke #9.

I got the broken one out, when I get a new one how do I put it back in without damaging the thread?

Broke #9.

Comment