yes but the pistons do not make the displacement alone. stroke and bore combined. an 84mm bore with an 89.6mm crank and any of the different piston combinations will still give you 3.0L of displacement.

MM sells pistons that give you compression and clearance based on your bore, stroke and rods.

the pistons for the 3.2 are for an oversized bore(86.5mm?) with an 89.6mm crank, can't remember if they use the same 135mm rods or not...

It can be done, but I'm trying to do it(~3.0L) without buying a $2000 kit, since so much of my $ is going into other parts, including headwork.

3.0L, 84mm bore, 89.6mm crank?

Collapse

X

-

After reading your post it got me thinking. Unfortunately I lost all of my notes from the build.SO I called MM and looked into it a lil more. The set of pistons I bought we're for a 2.9 m20 with 10.5:1 compresion and not the 3.0 I had orig thought. So you were correct about that. However they DO sell pistons for a 3.0 and even a 3.2 M20 so it CAN be done.Leave a comment:

-

you cannot get 3 liters out of an eta or TD crank.

what you have is a 2.8, not a 3.0.

sounds like a fun motor, regardless.Leave a comment:

-

Wether or not this helps you idunno? But what I did for my 3.0 was bore out a 2.7eta. I used MM custom pistons, a 524td crank, 325i rods, an 885 head ported and polished, schrick 304 cam and schrick springs, euro 323i distributor, distributor delete timing belt covers from the 323i as well, and three weber 40 IDF down draft carbs on a magaletsi manifold and it all works very well together... :)

Leave a comment:

-

I have to get the spare head on the bandsaw so I can take measurements from the cross section to find the depth of cut for valve reliefs.

The jig for holding the pistons is a pipe fixture(with 4 bolt flange) bored to a tight fit for the piston, with split sides and bolt/nut welded to tighten the split. Should be able to hold it nicely on the lathe and on an incline table on the cnc.

Once I have a block I can play with, I can get the parts in and see where material needs to come off just for clearance, then measure compressed CCs. I have the ability to dish the piston on the CNC, and doing something similar to the MM rally dish would be the simplest.

I'm moving soon so I won't be pulling the engine for at least a couple weeks.If I had a spare block I could get to it right away...Last edited by supernaughtIX; 05-12-2012, 04:12 AM.Leave a comment:

-

pffft. I went over some measurements and this is going to be easy. some light bevel and the piston will work. Its just a matter of cutting for compression!

When I have the jig made up and have some decent measurements, I'll post the amount of material needed to be removed in the bevel cut, etc.Leave a comment:

-

Are there any documents that describe the different pistons in detail? Something with dimensions maybe?

I read an old bfc thread that mentioned a bmw training manual that might have this kind of info.

I'd like to compare pistons before I start making chips and find out I went too deep.Leave a comment:

-

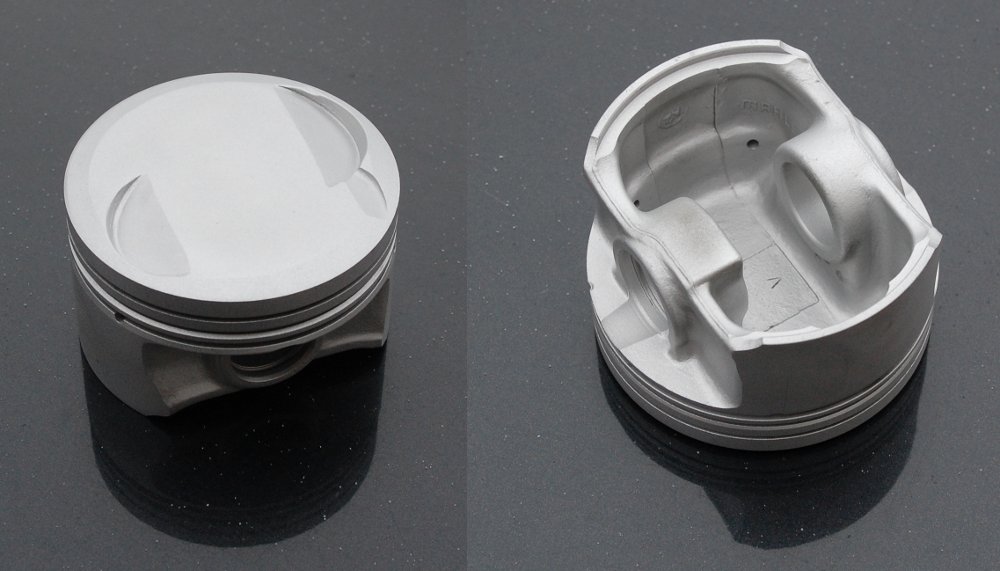

whoa. ok, I've got some M54 pistons, but they are not the same as these that iXer used:

The crowns on the pistons I have look shorter than those. I'm measuring them in the morning to be sure of thickness, but I'm not sure how much I can cut out. And what minimum should I leave under the relief?

We are making a jig to hold the pistons on an angle block to machine the reliefs on the cnc, but if I don't have enough crown material, I might have to look at other piston options.

I used a crude measuring method just now, but looks close to 7mm thickness and ~5mm to the first ring groove.Last edited by supernaughtIX; 04-03-2012, 05:44 PM.Leave a comment:

-

How much for your M54B30 pistons? I'd like to see what I accomplish by turning them on a lathe.Leave a comment:

-

-

With the 272 i would shoot for 9.5 or even 10:1. 9:1 is really too low to be used with an aftermarket cam.Leave a comment:

-

Top end is mostly done at the moment, just standard mods: oversized valves, 272 cam, heavy duty rockers and adjustable cam gear. When I put it on that block (in a few months) it should have M30B35 injectors and throttle body as well.

Last edited by Raxe; 03-29-2012, 08:05 PM.

Last edited by Raxe; 03-29-2012, 08:05 PM.Leave a comment:

-

Yes, I know the pistons must be machined... and I know the the exact c/r will depend on how and how much they are machined...

Stock m54b30 is 10.5:1, iirc. But that is with an entirely different head

And I read the thread just fine the first time

Sent from my Vortex using TapatalkLeave a comment:

-

Leave a comment: