Eta:

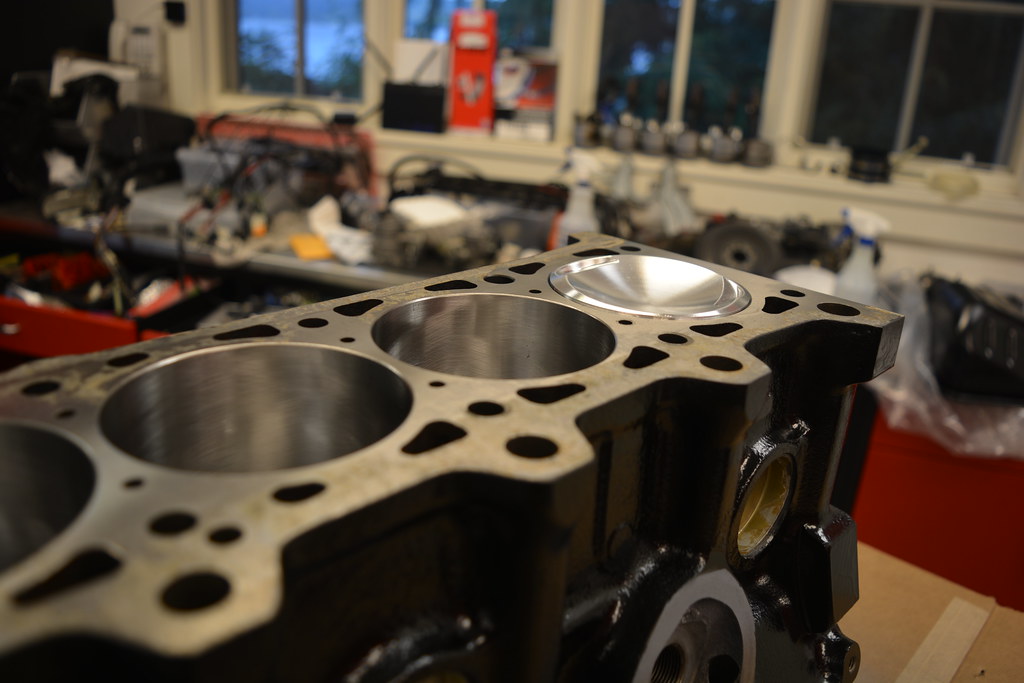

SuperEta:

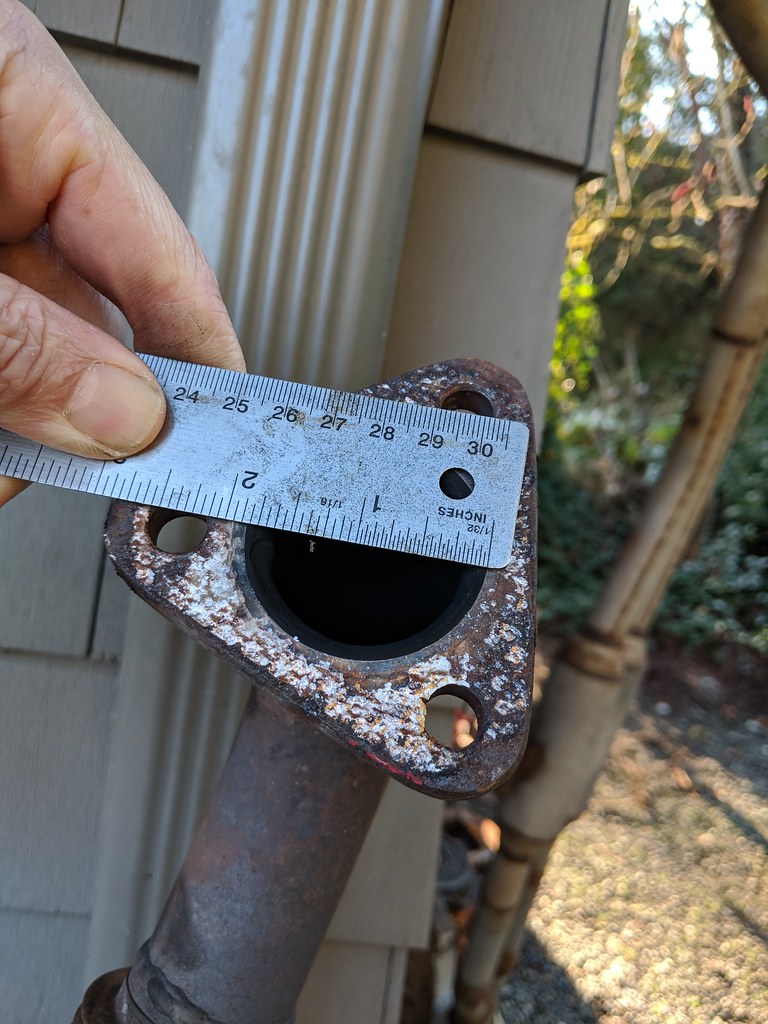

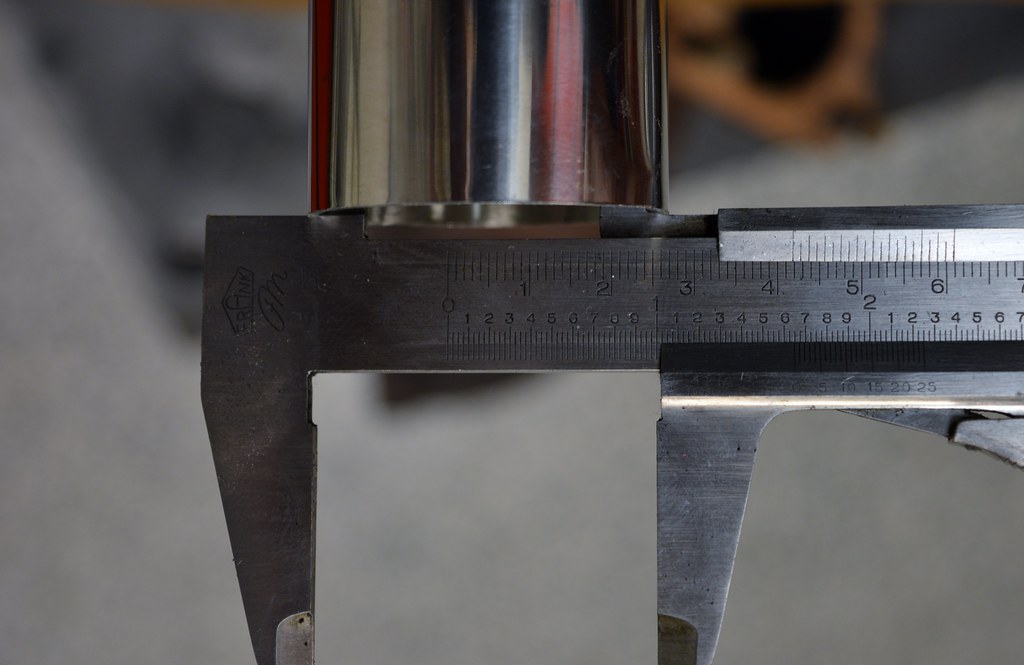

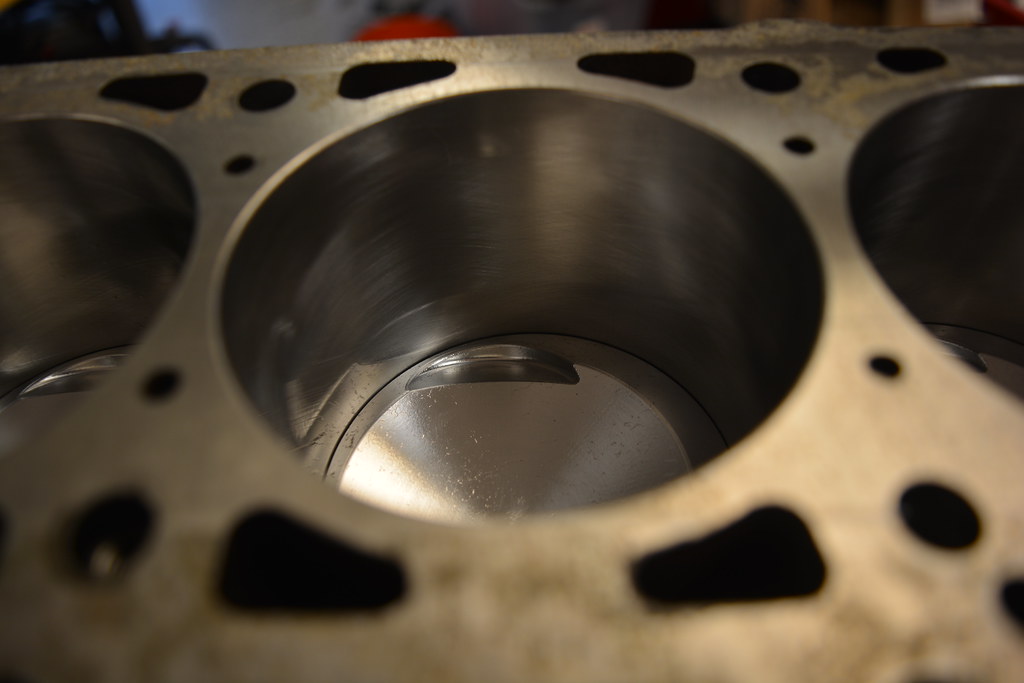

I should use a caliper, but it looks like ~1.75 *ID*.

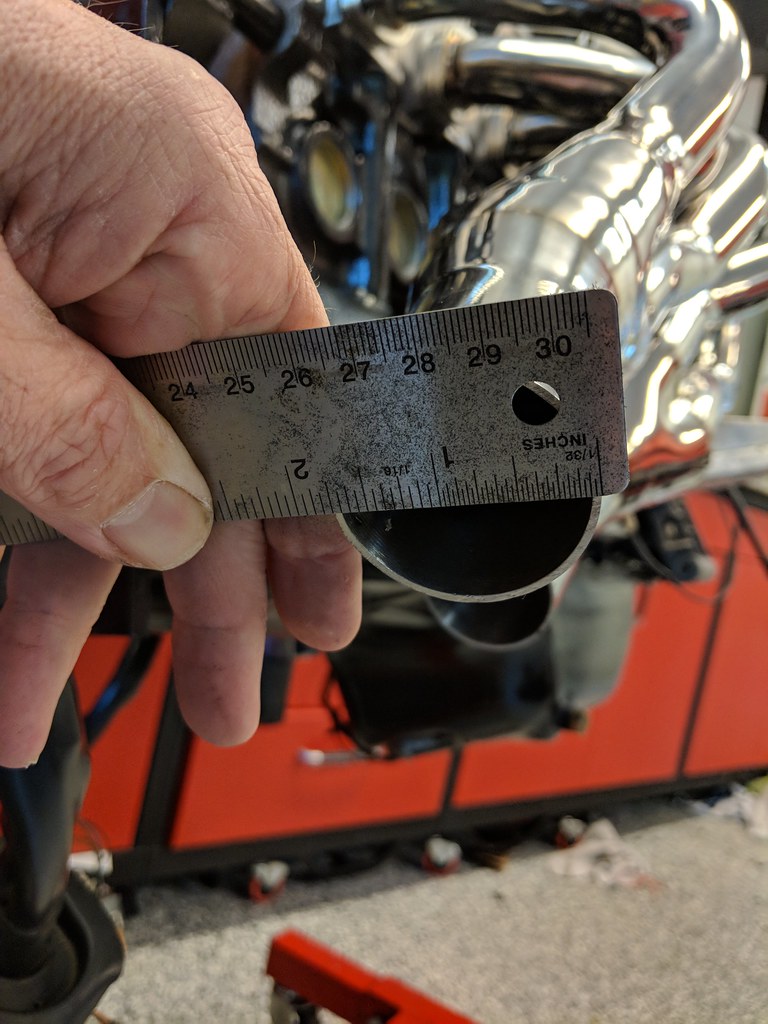

I've been working through the design of the exhaust and decided to measure the OBX header down pipes. Internet description says "2.5 OD" but that would be insane for an M20. I measured. 1.75" OD. Actually SMALLER than both the down pipes above:

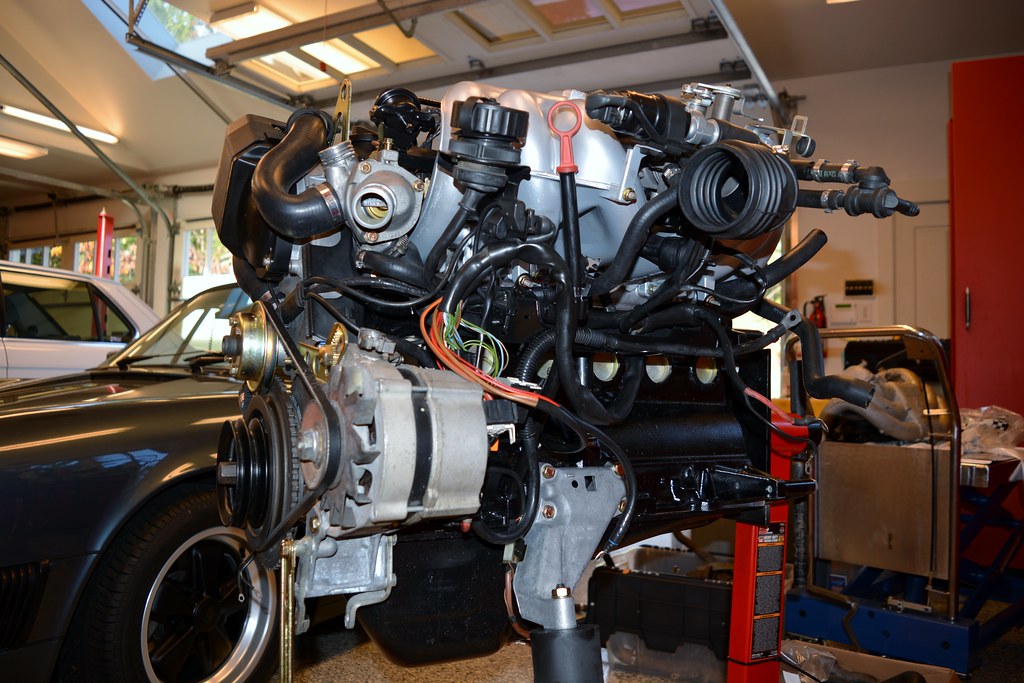

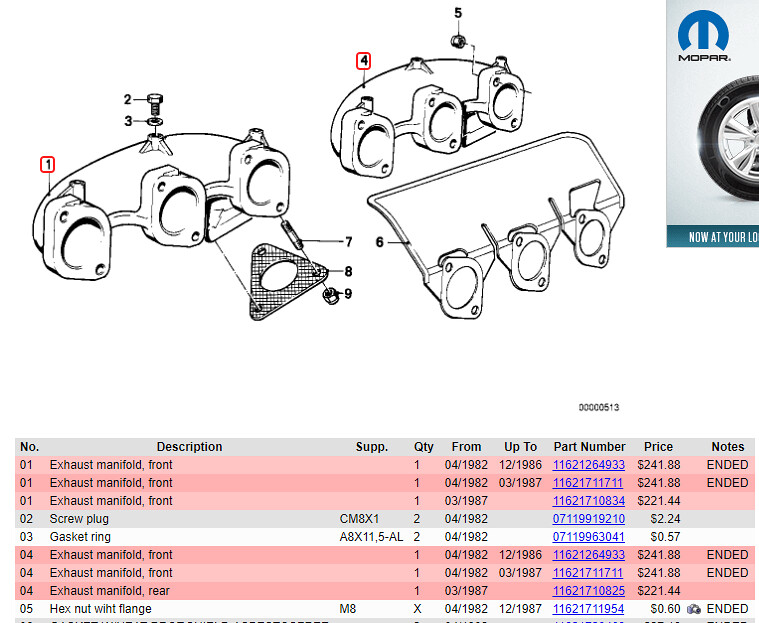

Right now I'm thinking I'll return the OBX Headers and just go with the 325i manifolds I have.

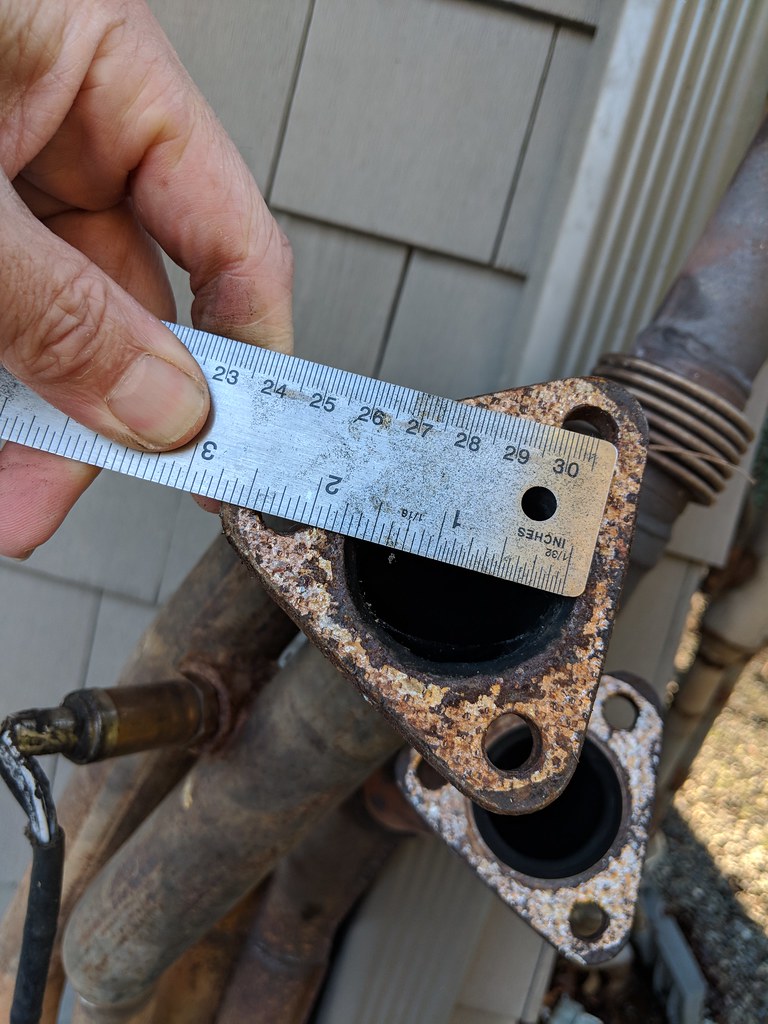

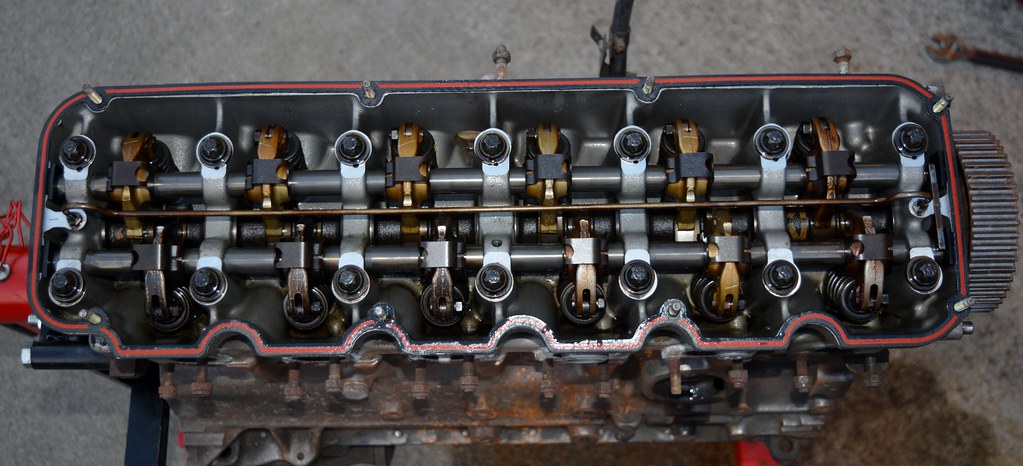

The SuperEta exhaust is in the middle (the exhaust on the right is from the turbo M30 car I parted out; Stromug). Note I'm missing the front down pipe to manifold connector piece. Anyone got a Seta exhaust lying around with this piece on it you'd be willing to give up?

The thinking is I'll use the Seta downpipe to the cat (where the hanger is) putting in a 45 degree mandrel to a Mangaflow 12268 (5x8x18 24" OAL) or 12368 (5x8x24" 30" OAL) as a 'resonator'. I like the idea of a little more sound suppression from the larger muffler, but not sure of what the cons might be (or if it'll be too long; haven't measured yet).

Then from there I'll use some 2.5" pipe and 2 45 degree mandrel to a Magnaflow 12866 (5x5x14" 20" OAL) and weld on dual tips (this is what @Joel323 did on @plndr's 533):

The Super Eta exhaust is dual all the way back.

The Eta exhaust is dual to just after the cat.

I think I'm going to just use the downpipe from the Eta and fab up a dual (or single 2.5") from the resonator back.

(I have not been able to source a Super Eta downpipe that isn't missing a part like mine is).

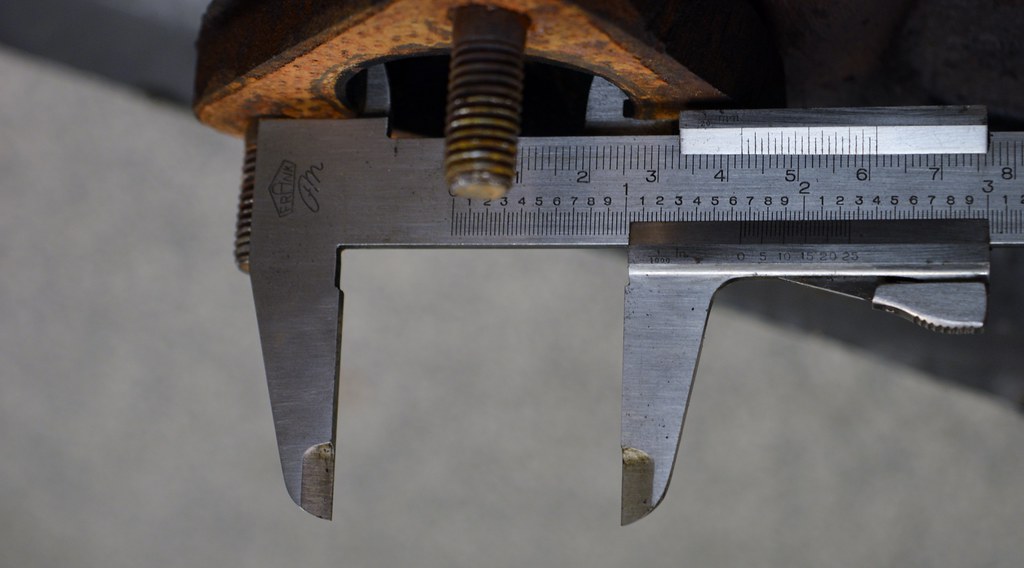

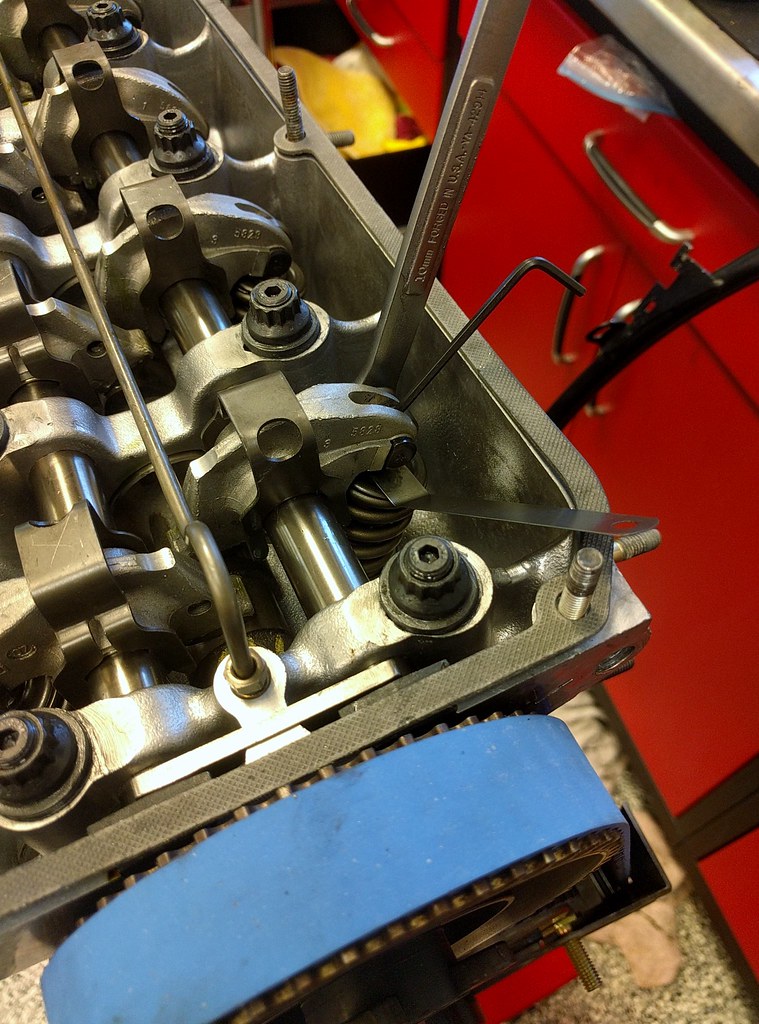

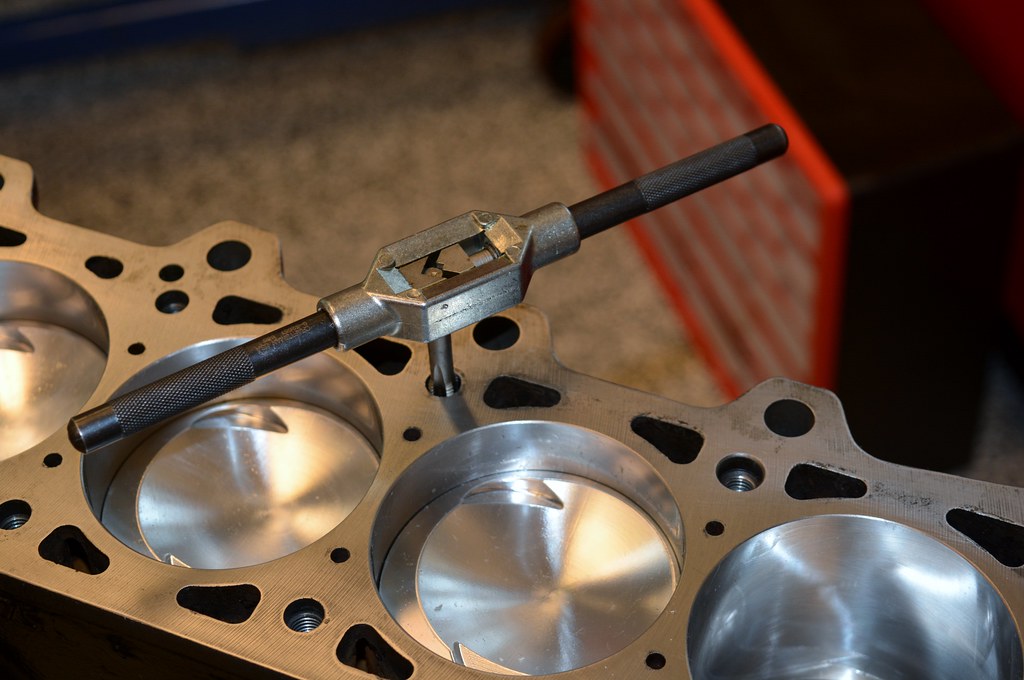

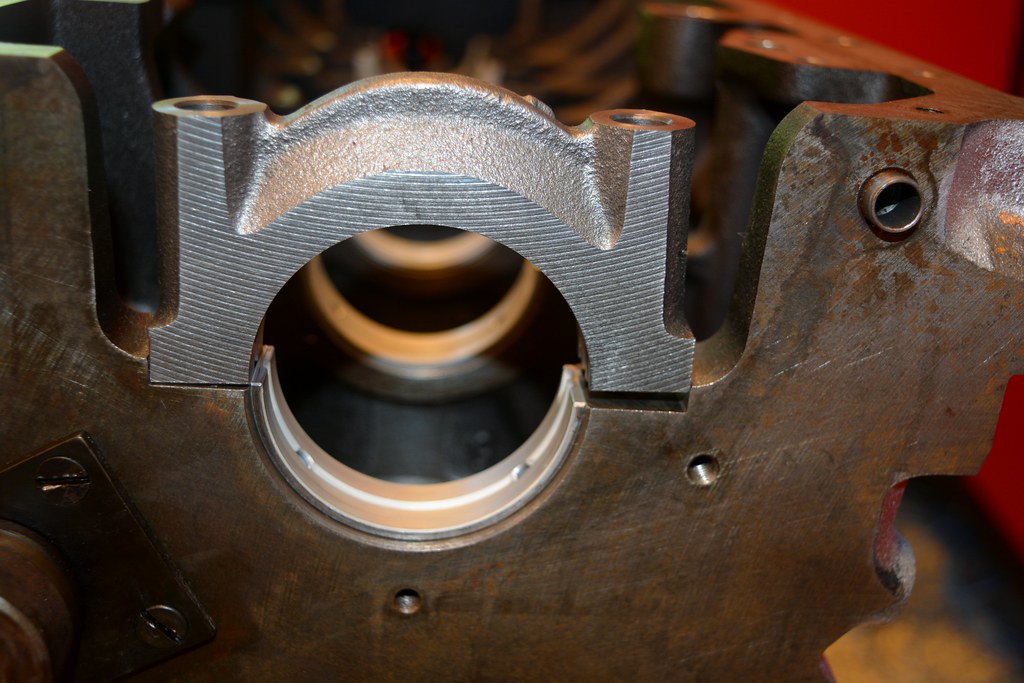

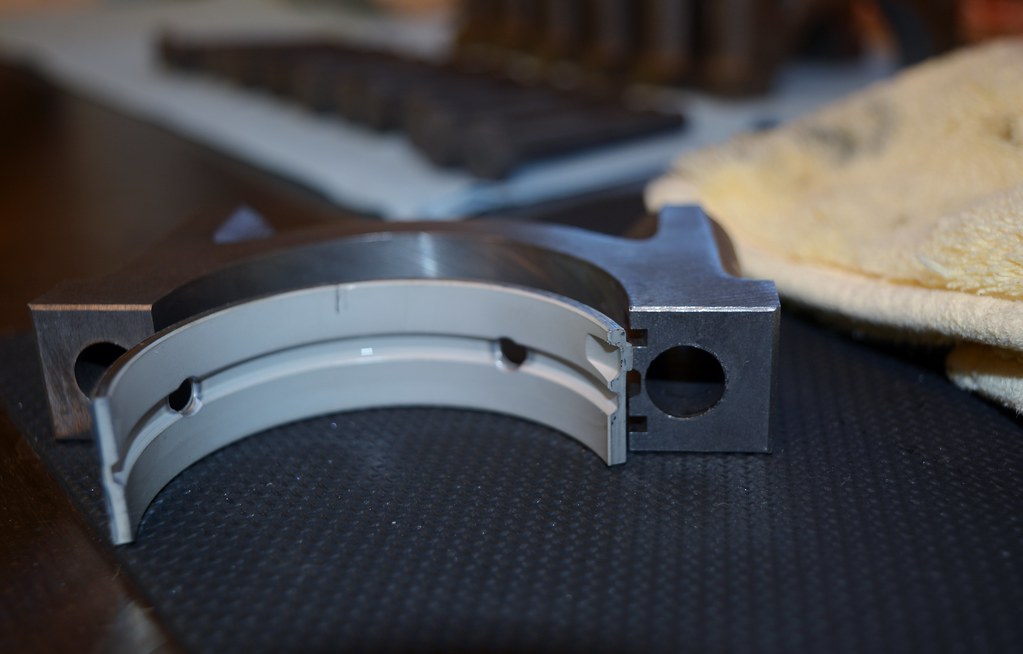

Super Eta/Eta manifolds have an inlet ID of 42mm and an outlet ID of 33mm:

Obx Inlet ID is 37mm.

Obx Outlet ID is 42mm.

Initially, so I can get the car off the lift as soon as possible, I'm just going to use the Eta exhaust as-is, as was the original plan.

Leave a comment: